Method for improving wear resistance of surface of iron-based powder metallurgy product by electron beam remelting

An iron-based powder metallurgy and electron beam remelting technology, applied in the field of powder metallurgy, can solve the problems of insufficient surface mechanical properties of iron-based powder metallurgy products, and achieve the effects of small deformation of the workpiece, small heat input, and small thermal influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

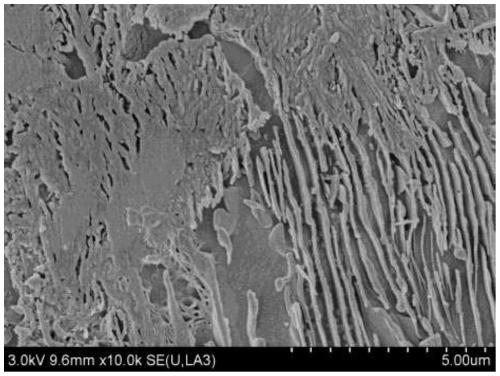

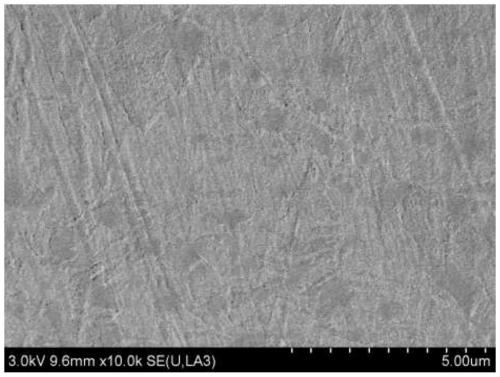

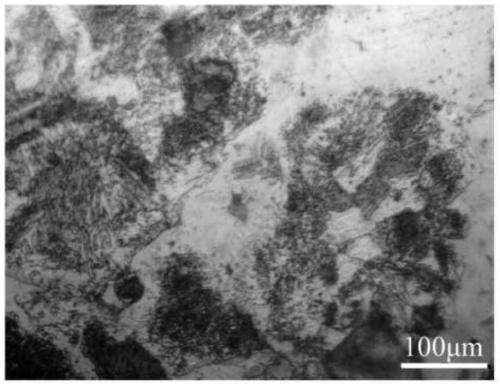

Image

Examples

Embodiment 1

[0026] First, the metal powder is formed by 23T pressure, and then sent to the mesh belt type sintering iron furnace for sintering. It is kept at 1000°C and 1080°C for 6 minutes, and at 1120°C for 30 minutes, and then slowly cooled in the furnace. During the sintering process, the furnace Into the hydrogen, prepared into iron-based powder metallurgy products.

Embodiment 2

[0028] First, the metal powder is formed by 23T pressure, and then sent to the mesh belt type sintering iron furnace for sintering. It is kept at 1000°C and 1080°C for 6 minutes, and at 1120°C for 30 minutes, and then slowly cooled in the furnace. During the sintering process, the furnace Hydrogen is introduced into the medium to prepare iron-based powder metallurgy products.

[0029] Fix the sintered powder metallurgy product on the workbench, seal the molding cavity and pump it to a high vacuum state; then use an electron beam with a current of 8mA to scan the surface of the sample with a voltage of 60kV, a scanning speed of 10mm / s, and maintain a heat output of 3J / mm , and then cut out a small middle part for inlaying, so as to observe the change of its cross-sectional properties later.

Embodiment 3

[0031] The difference between this embodiment and Embodiment 2 is that a 9 mA electron beam is used, and the voltage, scanning speed, and heat output of the electron beam remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com