Thermally-conductive and electrically-conductive adhesive and preparation method and application thereof

A technology for conductive adhesives and uses, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems affecting the solderability of conductive adhesives, increase the viscosity of conductive adhesives, and adversely apply conductive adhesives, and achieve accelerated curing. process, good weldability, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

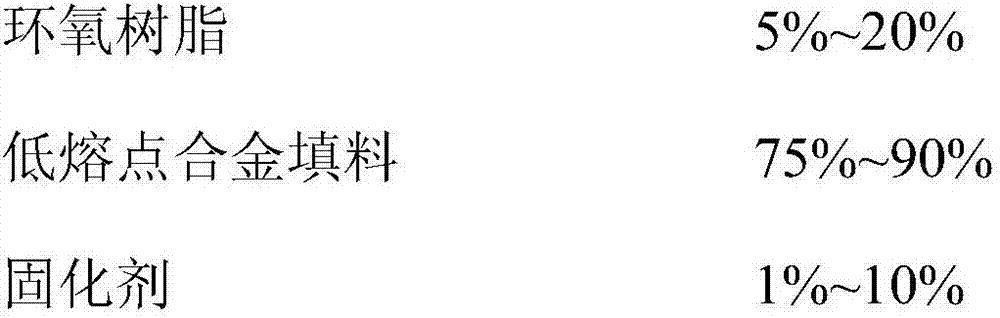

Method used

Image

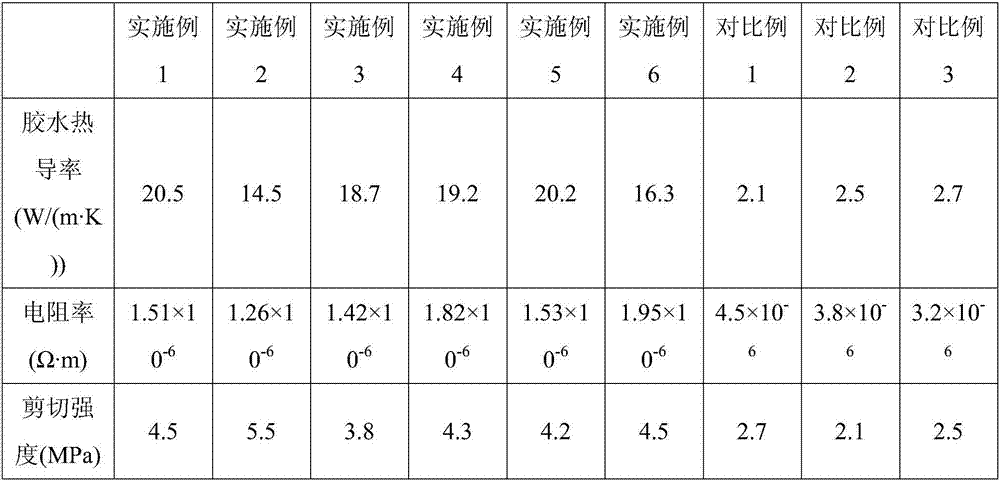

Examples

Embodiment 1

[0047] A heat-conducting and electrically-conducting adhesive, which consists of 15 parts of a resin matrix and 85 parts of a low-melting-point alloy filler in parts by mass;

[0048] The resin matrix is composed of bisphenol A diglycidyl ether, methyl hexahydrophthalic anhydride, amine curing agent, neopentyl glycol glycidyl ether, 1,6-hexanediol diglycidyl ether, hydrogenated castor oil, diethyl Tetramethylimidazole, polymerized rosin and acrylic resin modified maleic rosin are mixed according to the weight ratio of 100:80:2:1:1:2:1:1:1; the low melting point alloy filler is Cu, Ag, SnBi, SnBiAg, SnBiCu and SnInBi filler powders are mixed according to the weight ratio of 1:1:80:20:5:5.

[0049] The preparation method of the thermally conductive adhesive comprises the following steps:

[0050] Step 1, mixing the low melting point alloy filler and the resin matrix in proportion;

[0051] Step 2. Put the mixing tank into the mixer and vacuum mix the mixture evenly;

[0052...

Embodiment 2

[0054] A heat-conducting and electrically-conducting adhesive, which consists of 12 parts of a resin matrix and 88 parts of a low-melting-point alloy filler in parts by mass;

[0055] The resin matrix is composed of bisphenol A diglycidyl ether, methyl hexahydrophthalic anhydride, neopentyl glycol glycidyl ether, 1,6-hexanediol diglycidyl ether, diethylene glycol glycidyl ether, hydrogenated castor oil, Ethylene bis-stearin, imidazole, hydrogenated rosin, and maleic rosin are mixed according to the weight ratio of 100:85:2:1:1:2:1:2:1:1; the low melting point alloy filler is Cu, Ag, SnBi, SnBiCu and SnIn filler powders are mixed according to the weight ratio of 1:1:60:20:5.

[0056] The preparation method of the thermally conductive adhesive comprises the following steps:

[0057] Step 1, mixing the filler and the resin matrix in proportion;

[0058] Step 2. Put the mixing tank into the mixer and vacuum mix the mixture evenly;

[0059] Step 3, the slurry after mixing is t...

Embodiment 3

[0061] A heat-conducting and electrically-conducting adhesive, which consists of 10 parts of a resin matrix and 90 parts of a low-melting-point alloy filler in parts by mass;

[0062] The resin matrix is composed of bisphenol F epoxy resin, aliphatic epoxy resin, 2-ethyl-4-methylimidazole, 2-undecylimidazole, 1,4-butanediol glycidyl ether, neopentyl Glycidyl ether, hydrogenated castor oil, triethylamine, and maleic rosin are mixed according to the weight ratio of 85:15:70:10:2:3:2:2:3; the low melting point alloy filler is Cu, Ag , SnBiAg, SnBiCu and SnIn filler powders are mixed according to the weight ratio of 1:1:75:25:5.

[0063] The preparation method of the thermally conductive adhesive comprises the following steps:

[0064] Step 1, mixing the filler and the resin matrix in proportion;

[0065] Step 2. Put the mixing tank into the mixer and vacuum mix the mixture evenly;

[0066] Step 3, the slurry after mixing is the obtained conductive adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com