High-performance water-based phase change coating and preparation method thereof

A water-based, high-performance technology, applied in the direction of microsphere preparation, epoxy resin coating, chemical instruments and methods, etc., can solve the problem of poor adhesion and coating stability of phase change microcapsules, decreased coating stability, and difficult stability Construction and other issues, to achieve the effect of improving heat transfer and heat absorption performance, improving stability, and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

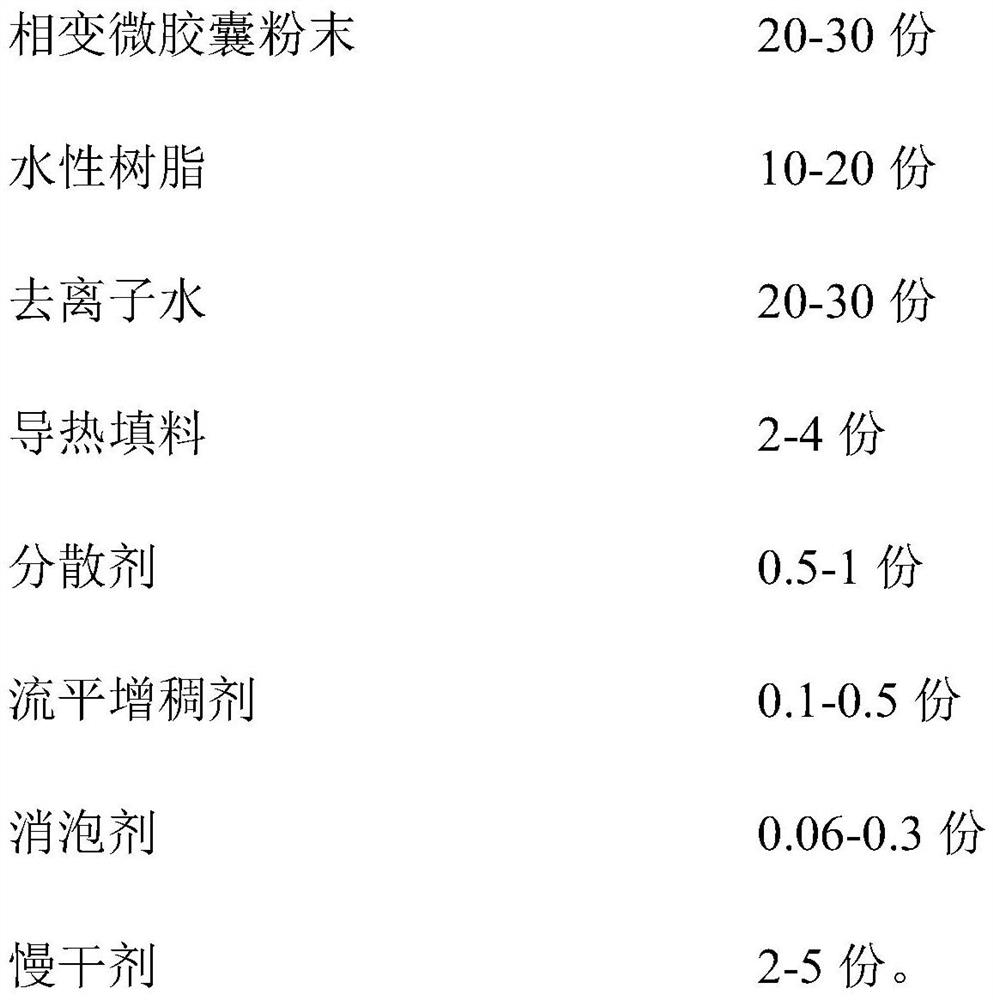

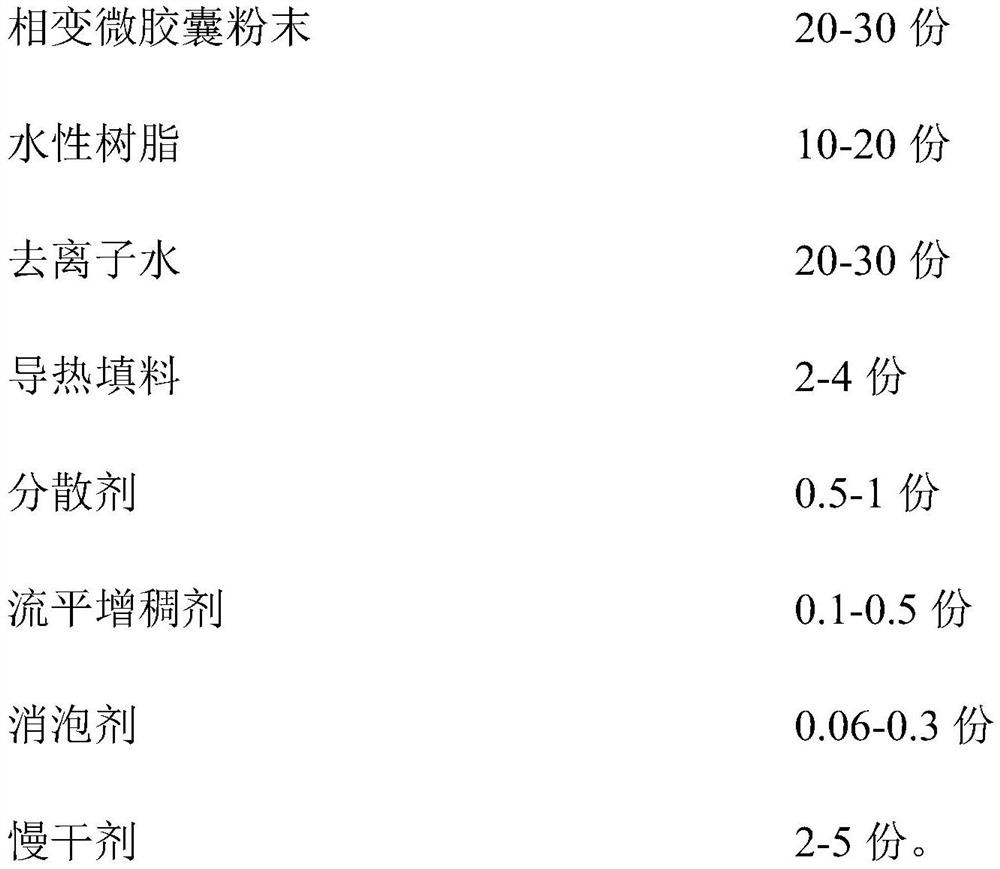

Method used

Image

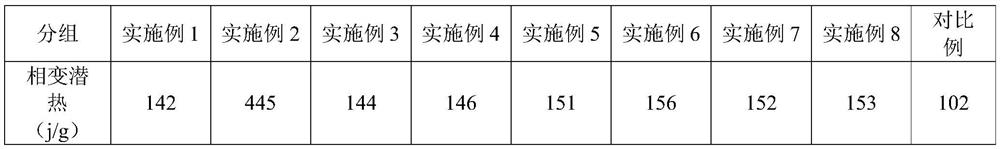

Examples

Embodiment 1

[0044] Add 5g of sodium dodecylbenzenesulfonate to 200g of deionized water, mix and stir at room temperature until the sodium dodecylbenzenesulfonate is completely dissolved, transfer the mixed system to an ultrasonic stirrer, add 200g of melamine Resin phase-change microcapsule powder and 20g of alumina were stirred ultrasonically for 10 minutes, and then 0.6g of polyether defoamer was added to obtain a dispersion;

[0045] Add 100g of water-based acrylate to the dispersion, stir at room temperature for 10min, after stirring, add 1g of polyurethane associative thickener HY-304D, stir, adjust the viscosity of the system to 3000-6000cp, and finally add 20g of ethanol to obtain a mixture, And the mixture was placed in a vacuum box at room temperature to defoam for 60 minutes to obtain a phase change coating.

Embodiment 2

[0047]Add 10g of alkylnaphthalene sulfonate to 300g of deionized water, mix and stir at room temperature until the alkylnaphthalene sulfonate is completely dissolved, transfer the mixed system to an ultrasonic stirrer, add 300g of melamine resin phase change Microcapsule powder and 40g of aluminum nitride were ultrasonically stirred for 20 minutes, and then 3g of polyether defoamer was added to obtain a dispersion;

[0048] Add 200g of water-based polyurethane to the dispersion, stir at room temperature for 60min, add 5g of methyl cellulose ether after stirring, stir to adjust the viscosity of the system to 3000-6000cp, finally add 50g of ethanol to obtain a mixture, and place the mixture in a vacuum Defoaming in the box at room temperature for 10 minutes to obtain a phase change coating.

Embodiment 3

[0050] Add 6 g of dihexadecyl dimethyl ammonium oxide to 220 g of deionized water, mix and stir at room temperature until the dihexadecyl dimethyl ammonium oxide is completely dissolved, transfer the mixed system to an ultrasonic stirrer, Add 220g of melamine resin phase change microcapsule powder and 30g of ultrafine graphite, stir ultrasonically for 30min, then add 1g of polyether defoamer to obtain a dispersion;

[0051] Add 120g of water-based epoxy resin to the dispersion, stir at room temperature for 20min, add 2g of ethyl cellulose ether after stirring, stir, adjust the viscosity of the system to 3000-6000cp, finally add 30g of ethylene glycol to obtain a mixture, and The mixture was placed in a vacuum box at room temperature to defoam for 20 minutes to obtain a phase change coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com