Fiber reinforced composite structure comprising stitch-member and the method for producing the same

A technology of reinforced composites and manufacturing methods, applied in the direction of fiber chemical characteristics, chemical instruments and methods, vehicle parts, etc., can solve problems such as low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

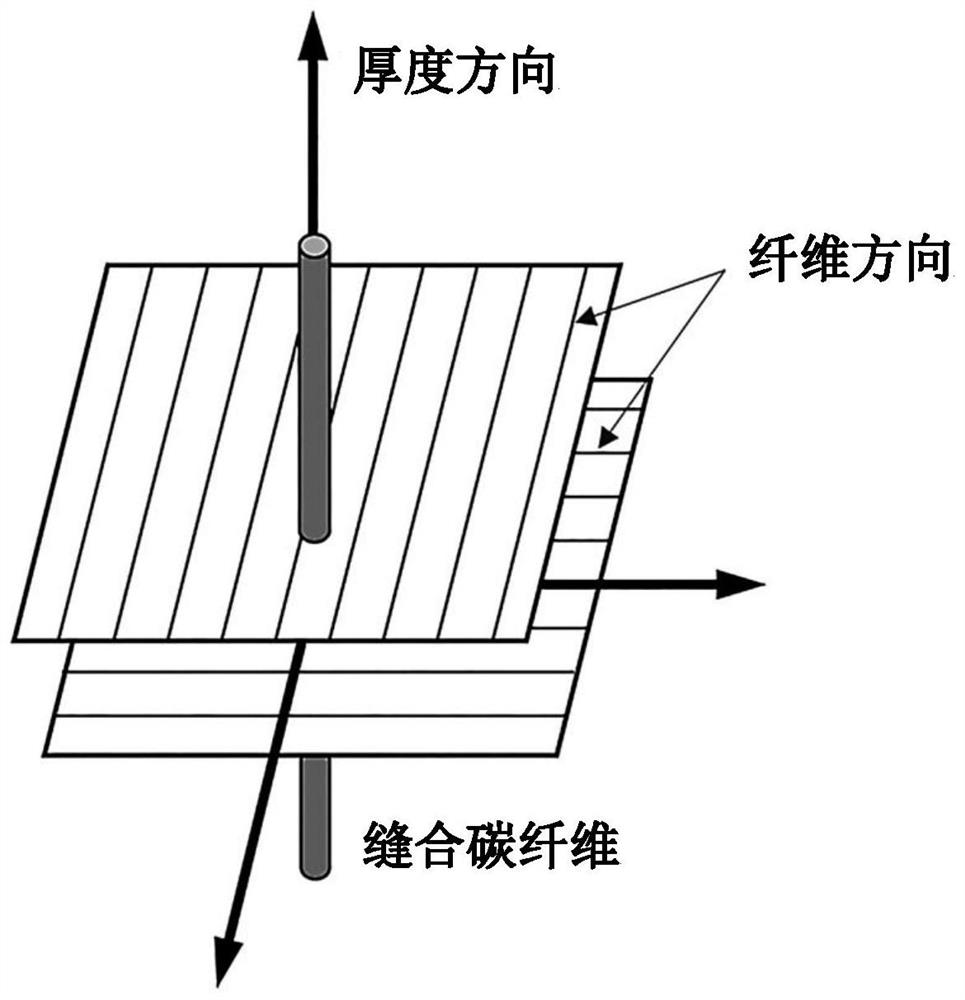

[0090] Example 1: Fiber-reinforced composite structure (primary suture, PAN system)

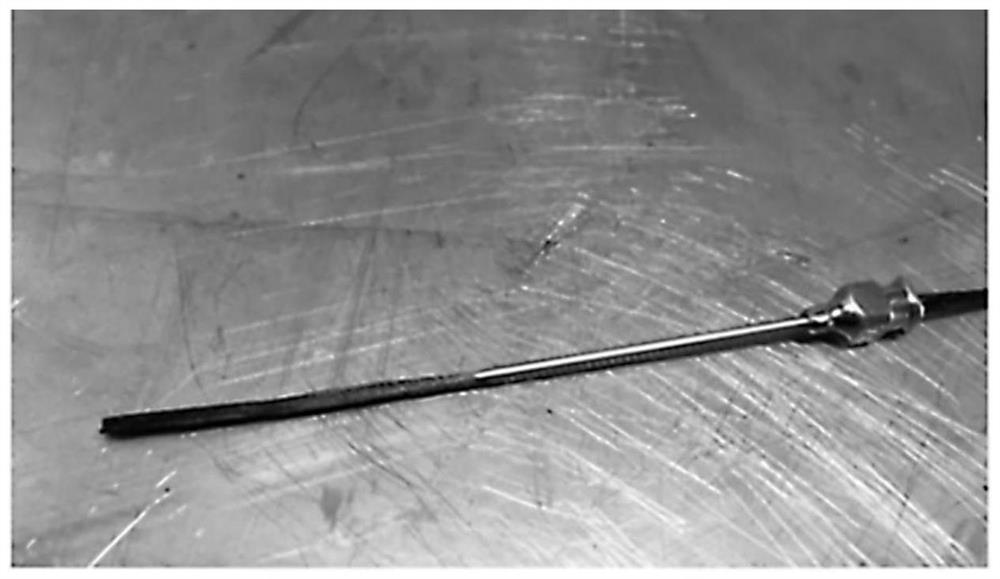

[0091] A prepreg containing PAN-based carbon fibers (USN200A, SK Company) was cut into a regular quadrilateral shape of 8 cm in width and length along directions perpendicular to and parallel to the direction of the fibers. For this prepreg sheet, odd-numbered layers were rotated by 0°, and even-numbered layers were rotated by 90° so that the directions of fibers of adjacent layers were perpendicular to each other, and 22 layers were stacked to manufacture a fiber-reinforced structure. Then, a PAN-based carbon fiber (T700, TORAY Co., Ltd.) was passed through a suture needle of a predetermined thickness, and this was used to suture one point inside a circle with a diameter of 19 mm in the fiber-reinforced structure. After the penetrating needle point is fully raised upwards, the fiber is pulled out so that the fiber becomes a pattern of penetrating the prepreg ( Figure 2c , 2d ). After the...

Embodiment 2

[0092] Example 2: Fiber-reinforced composite structure (primary stitching, asphalt system)

[0093] A fiber-reinforced composite structure was produced in the same manner as in Example 1 except that pitch-based carbon fibers (XN-90-60S, NGF) were used as carbon fibers to be stitched through the fiber-reinforced structure.

Embodiment 3

[0094] Example 3: Fiber-reinforced composite structure (4 sutures, PAN system)

[0095] A fiber-reinforced composite structure was produced in the same manner as in Example 1, except that four points inside a circle with a diameter of 19 mm in the fiber-reinforced structure were sewn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com