Preparation method of highly-unsaturated flaxseed oil fatty acid

A linseed oil fatty acid and unsaturated technology, which is applied in the fields of fatty acid preparation/refining, fatty acid production, fatty acid chemical modification, etc., can solve the problems of large waste water discharge, easy thermal oxidation, thermal polymerization deterioration, etc., and achieves small waste water discharge. , Universal, low energy consumption, high iodine value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

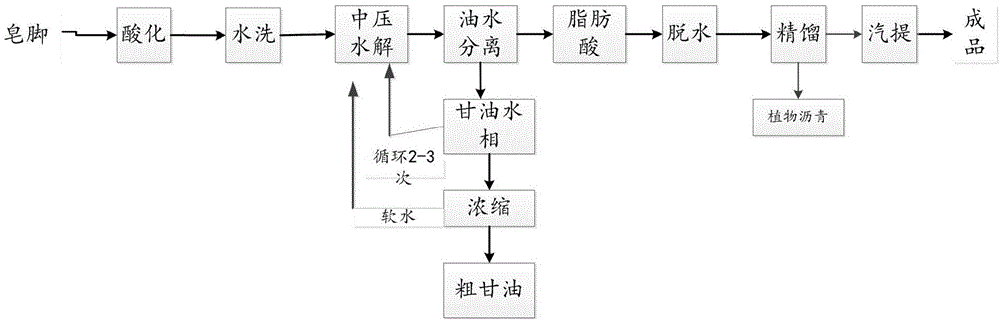

[0028] combine figure 1 , the preparation method of the highly unsaturated linseed oil fatty acid that the embodiment of the present invention 1 provides, comprises the following steps:

[0029] Step 1: Add 500kg of linseed oil soapstock into the acidification kettle, stir and heat to 90°C;

[0030] Step 2: Slowly add concentrated sulfuric acid with a concentration of 98% to the stirred and heated linseed oil soapstock for acidification for 1 hour, wherein the added amount of concentrated sulfuric acid is 5% of the weight of the linseed oil soapstock, and the pH value is 3;

[0031] Step 3: Keeping the temperature constant, adding a temperature of 90°C to the acidified linseed oil soapstock and washing with 5% sodium chloride solution in an amount of 5% of the weight of the linseed oil soapstock 10%, and repeated washing 3 times, after washing, the water in the lower layer was discharged to obtain the acidified oil in the upper layer;

[0032] Step 4: Put the acidified oil ...

Embodiment 2

[0039] The preparation method of the highly unsaturated linseed oil fatty acid that the embodiment of the present invention 2 provides comprises the following steps:

[0040] Step 1: Add 500kg of linseed oil soapstock into the acidification kettle, stir and heat to 95°C;

[0041] Step 2: Slowly add concentrated sulfuric acid with a concentration of 98% to the stirred and heated linseed oil soapstock for acidification for 2 hours, wherein the added amount of concentrated sulfuric acid is 8% of the weight of the linseed oil soapstock, and during acidification, the pH value is 4;

[0042] Step 3: Keeping the temperature constant, adding a temperature of 90° C. to the acidified linseed oil soapstock and washing with 8% sodium chloride solution in an amount of 8% by weight of the linseed oil soapstock 15%, and repeated washing 3 times, after washing, the water in the lower layer was discharged to obtain the acidified oil in the upper layer;

[0043] Step 4: Put the acidified oil ...

Embodiment 3

[0050] The preparation method of the highly unsaturated linseed oil fatty acid provided by the embodiment of the present invention 3 comprises the following steps:

[0051]Step 1: Add 500kg of linseed oil soapstock into the acidification kettle, stir and heat to 100°C;

[0052] Step 2: Slowly add concentrated sulfuric acid with a concentration of 98% to the stirred and heated linseed oil soapstock, and acidify for 0.5h, wherein the added amount of concentrated sulfuric acid is 10% of the weight of the linseed oil soapstock. During acidification, the pH value is 4;

[0053] Step 3: Keeping the temperature constant, adding a temperature of 95° C. to the acidified linseed oil soapstock, and washing with 10% sodium chloride solution by mass fraction, the amount of sodium chloride solution added is 1% of the linseed oil soapstock weight 20%, and repeated washing 2 times, after washing, drain the water in the lower layer to obtain the acidified oil in the upper layer;

[0054] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com