Method for preparing linseed oil fatty acid with light color

A technology for linseed oil fatty acid and linseed oil, which is applied in the directions of fatty acid preparation/refining, fatty acid production, etc., can solve the problems of excessively dark product color, consumption, and inability to produce light-colored products, and achieves the effect of environmental protection in the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

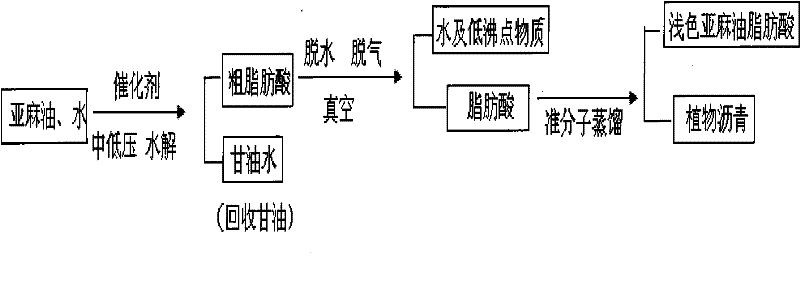

Image

Examples

Embodiment Construction

[0019] Put 7 tons of linseed oil and 3.5 tons of water into the hydrolysis kettle, then add 7kg of zinc oxide and 3.5kg of calcium oxide, adjust the pressure in the kettle to 1.3-1.5Mpa, stir and hydrolyze for 5 hours, let stand for half an hour to exhaust the sweet water and Soap (recycled separately). Add 3-4 tons of clear water again, heat to keep the pressure at 1.3-1.5Mpa, measure the acid value of the product every hour, when the acid value is higher than 190mgKOH / g, stop the hydrolysis, let go of the lower layer of glycerin water (for initial hydrolysis Feeding), the obtained crude fatty acid is put into the transition tank.

[0020] The crude fatty acid is naturally sucked into the dehydration kettle through vacuum, and the vacuum dehydration and degassing are carried out while it is hot. The temperature of the material is controlled at 100-120°C (the temperature is low, the temperature must be raised), and the vacuum degree is controlled at -0.098~-0.099MPa.

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com