Method for producing active carbon by using cinder of brown coal

A technology for the production of activated carbon and lignite slag, which is applied in the chemical/physical/physical-chemical processes of energy application, and the removal of solid wastes. Low production cost, high product quality, overcoming the effect of cold centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

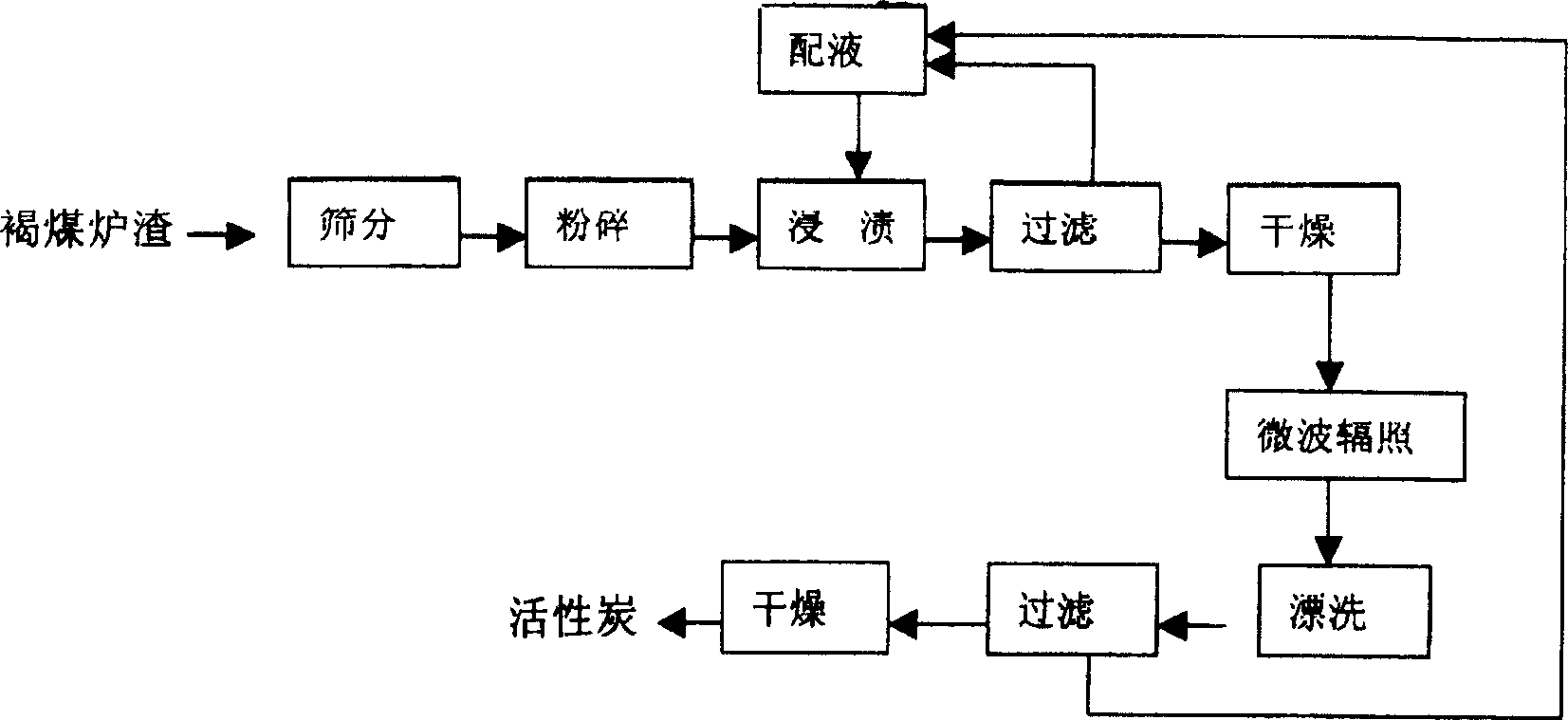

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The raw material is the slag of the Lurgi pressurized gasifier. Ingredients (percentage by weight): carbon 40.50%, hydrogen 0.73%, sulfur 0.51%, nitrogen 0.51%, oxygen 7.32%, ash 43.70%.

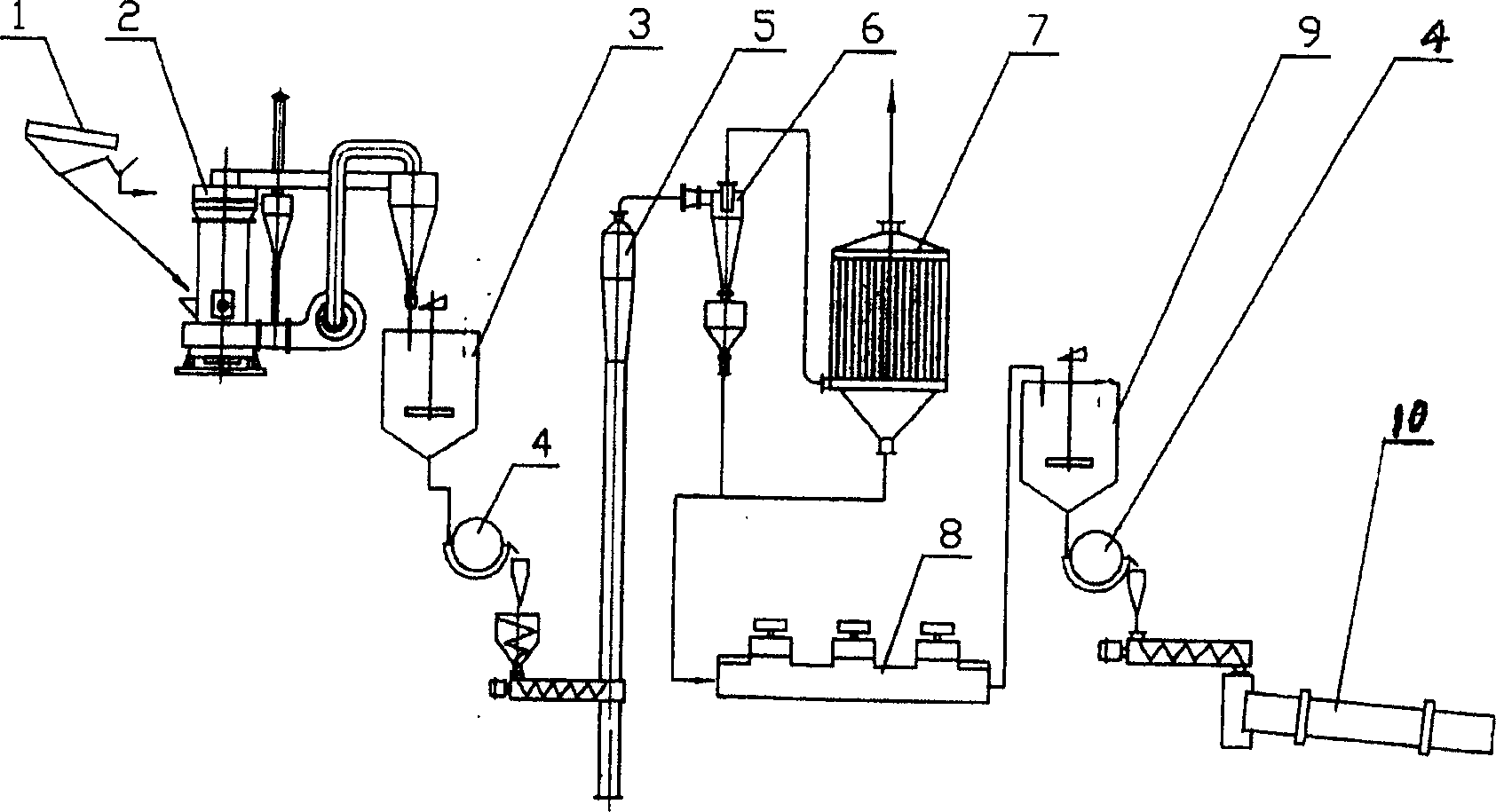

[0023] Pass the above raw materials through a vibrating classifier (1) to separate the large pieces of molten slag in the slag, use a Raymond mill (2) to crush the undersize to a particle size of less than 0.18mm, put the slag powder into the impregnator (3), and press The weight ratio of slag to caustic potash is 1:0.8, and caustic potash is prepared into an aqueous solution with a concentration of 30% by weight, and the slag is added to the prepared caustic potash solution, soaked for 4 hours, filtered with a vacuum filter (4), and the filtrate is returned for use , use the flue gas flow dryer (5) to dry the slag powder filtered out at 120 ° C, and the dried powder is separated in the separator (6) and the pulse bag filter (7), and put into a box-type microwave oven (8...

Embodiment 2

[0024] Embodiment 2: raw material is lignite slag, composition (weight percentage): carbon 45.6%, hydrogen 3.14%, nitrogen 1.21%, sulfur 1~2.4%, oxygen 14.15%, ash content 20~22.19%, moisture content 10.70% .

[0025] The above-mentioned raw materials are passed through a vibrating classifier (1) to separate the large pieces of slag in the slag, and the underscreen is crushed with a Raymond mill (2) until the particle size is less than 0.18mm. The ratio of slag to caustic potash is 1: 1.1, and the slag is added to the potassium hydroxide solution with a concentration of 40% by weight, soaked for 5-6 hours, filtered with a vacuum filter (4), and the filtrate is returned for use. Put the filter cake into a box-type high-temperature microwave oven (8), heat to 800°C-900°C for 2-3 minutes, and 900°C-1100°C for 5-10 minutes to obtain powdered activated carbon.

[0026] In above-mentioned embodiment, if the carbon content of raw material is low, then the specific surface area and i...

Embodiment 3

[0027] Embodiment 3: Irregular granular activated carbon and columnar activated carbon

[0028] After the powdered activated carbon obtained in the above two examples is mixed with 15-25% carboxymethyl cellulose and 10-25% calcium carbonate by weight, it is extruded and heated to 350- 450 ° C, heat preservation for 10-20 minutes, that is, columnar activated carbon is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com