Activated carbon preparation method

A technology of activated carbon preparation and carbon powder, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems affecting product indicators, integration, etc., and achieve the effect of improving iodine value, high efficiency and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

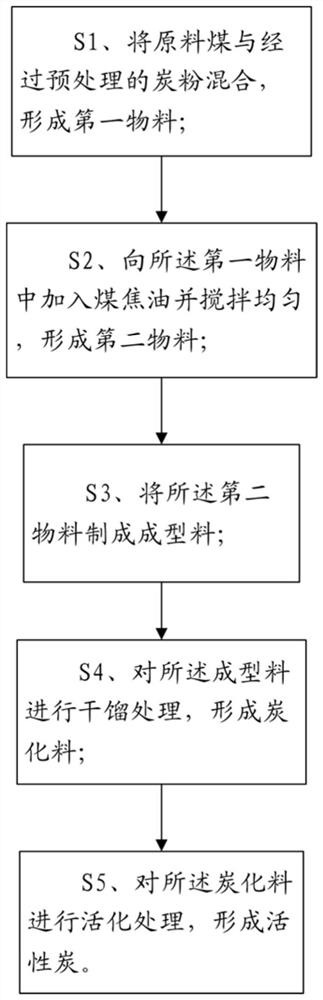

Method used

Image

Examples

Embodiment 1

[0060] Referring to Table 1, in this example, anthracite, coking coal and semi-coke were crushed and pulverized according to the mass ratio of 2:3:5 to obtain raw coal, and its fineness meets the requirement that the sieving rate on a 325 mesh Taylor standard sieve is greater than 90 %; the charcoal powder is crushed and pulverized, and its fineness meets the sieving rate of more than 90% on a 325-mesh Taylor standard sieve; the content of coal tar pitch meets 55wt%-65wt%.

[0061] Subsequently, raw coal, charcoal powder and coal tar are weighed and put into kneading equipment. In the raw coal, the ratio between anthracite, coking coal and semi-coke is constant, and it accounts for 99wt% of the first material, carbon powder accounts for 1wt% of the first material, and coal tar is 30wt% of the first material (not included in the first material). total material weight). The quality of raw coal and charcoal powder is placed in the kneading equipment from large to small. The knea...

Embodiment 2-11

[0065] Referring to Table 2, the difference between Examples 2-10 and Example 1 is that the content of carbon powder added to the raw material is different, while Example 11 does not add carbon powder to the raw material. Furthermore, it can also be seen from Table 2 that the corresponding indicators of the finished activated carbon obtained in different embodiments have also changed, and setting the carbon powder content to 1wt%-30wt% can maximize the reutilization of carbon powder, while using charcoal Among the indicators of activated carbon prepared from powder, iodine value≧330mg / g, wear resistance≧97%, compressive strength≧40kgf, desulfurization value≧15.4mg / g, denitrification rate≧54.8%. In the case of not using carbon powder in Example 11, its iodine value, desulfurization value and denitrification rate all decreased, that is, the iodine value and desulfurization value of activated carbon prepared by using carbon powder as one of the raw materials of activated carbon mi...

Embodiment 12

[0068] In embodiment 12, the waste material under active carbon sieve (unqualified material, without flue gas treatment) is raw material, coal tar is binder, other preparation process and control parameters are identical with embodiment 1, and the performance of the activated carbon prepared by it is The experimental statistics are shown in Table 3 below:

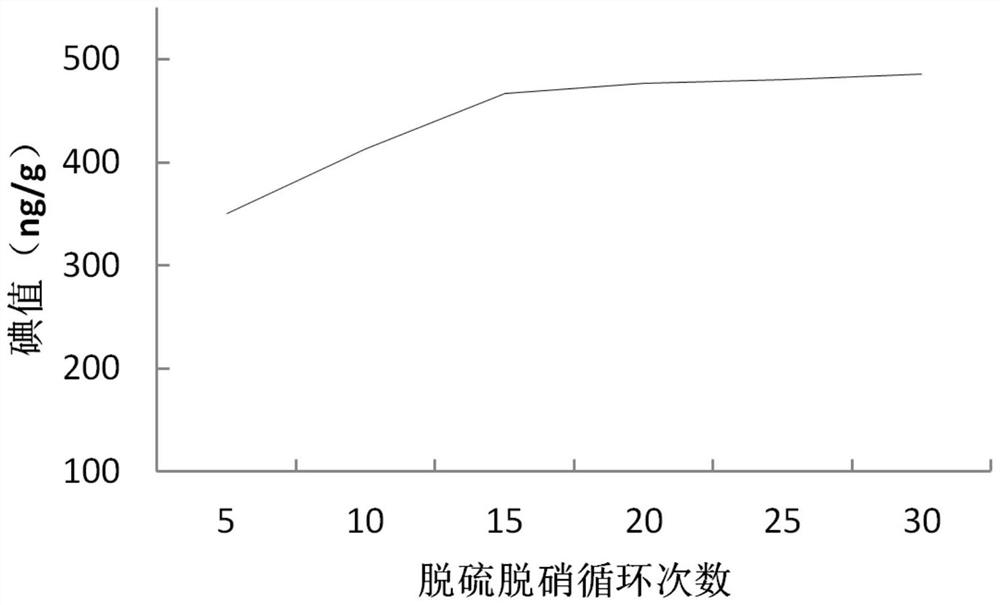

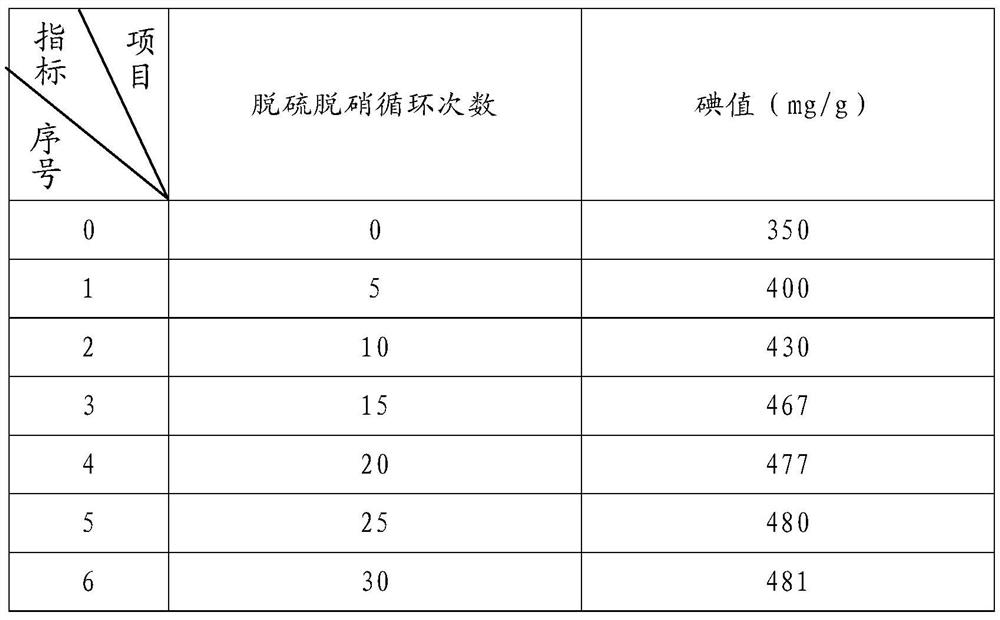

[0069]

[0070]

[0071] table 3

[0072] It can be seen that the iodine value, desulfurization value, and denitrification value of the activated carbon prepared by using the crushed material under the activated carbon sieve and raw coal as raw materials are still lower than the corresponding indicators of the activated carbon prepared in Examples 1-10. It can be seen that even if activated carbon is prepared by using the under-sieved material of activated carbon and raw coal, the performance index of the obtained activated carbon product is still insufficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com