Automatic system with road-surface rapid drying, cooling, snow removing and ice melting functions

An automation system and fast drying technology, applied in the field of automation systems, can solve problems such as installation and post-maintenance inconvenience, vehicle wheel slippage, traffic safety, and reduce the service life of road surfaces, so as to realize automatic operation, speed up road surface drying, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

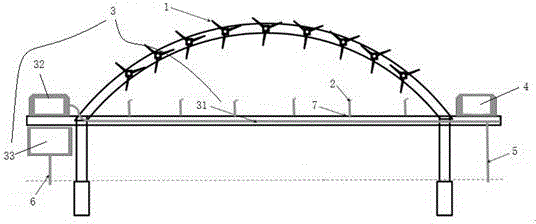

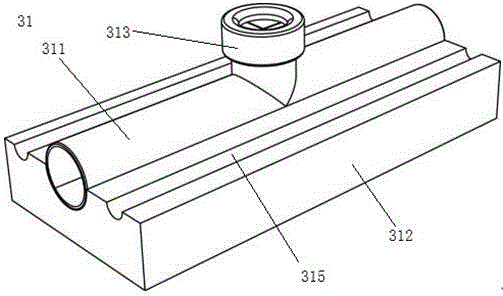

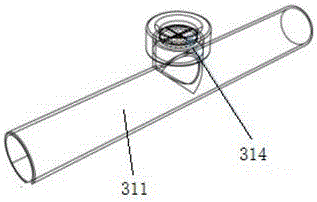

[0018] Such as figure 1 As shown, an automatic system for rapid drying, cooling and snow removal and ice melting of the road surface, including a wind power generator 1, a solar power generation circuit lamp 2 with solar power generation function, a road surface snow removal and ice melting device 3 and an energy management room 4, the wind power generator 1 is fixedly installed on the arc-shaped pole of the bridge span, the solar power circuit lamp 2 is fixedly installed on the road surface of the bridge, and the road surface snow removal and ice melting device 3 includes automatic pipeline components 31, 311 automatic pipelines and pressure pumps 32 pre-buried in the bridge road surface And the high-pressure boiler 33, the pressure pump 32 and the high-pressure boiler 33 are located on the same side of the bridge, the pressure pump 32 is fixedly connected with one end of the automation pipeline assembly 31, the other end of the automation pipeline assembly 32 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com