Construction method for pile body hole collapse or pile bottom sediment quality defect treatment of rotary excavating filling pile

A construction method and cast-in-place pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of lack of unified construction specifications, reduced pile bearing capacity, and many construction links, etc., and save piles or rework costs. , The effect of improving the construction speed and saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

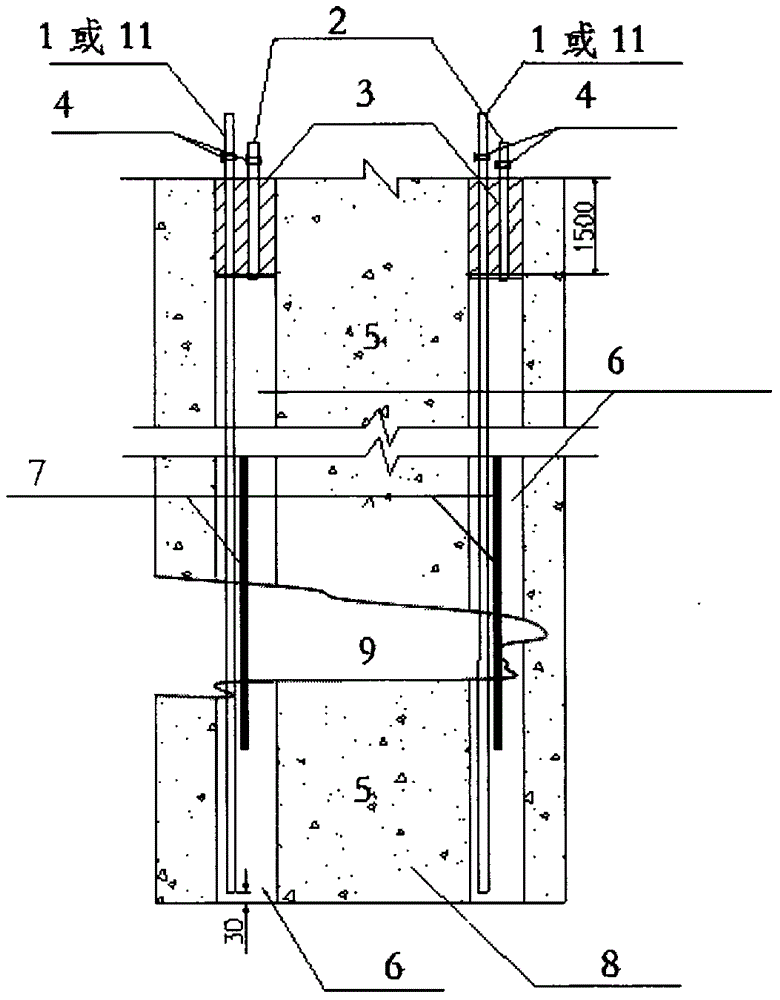

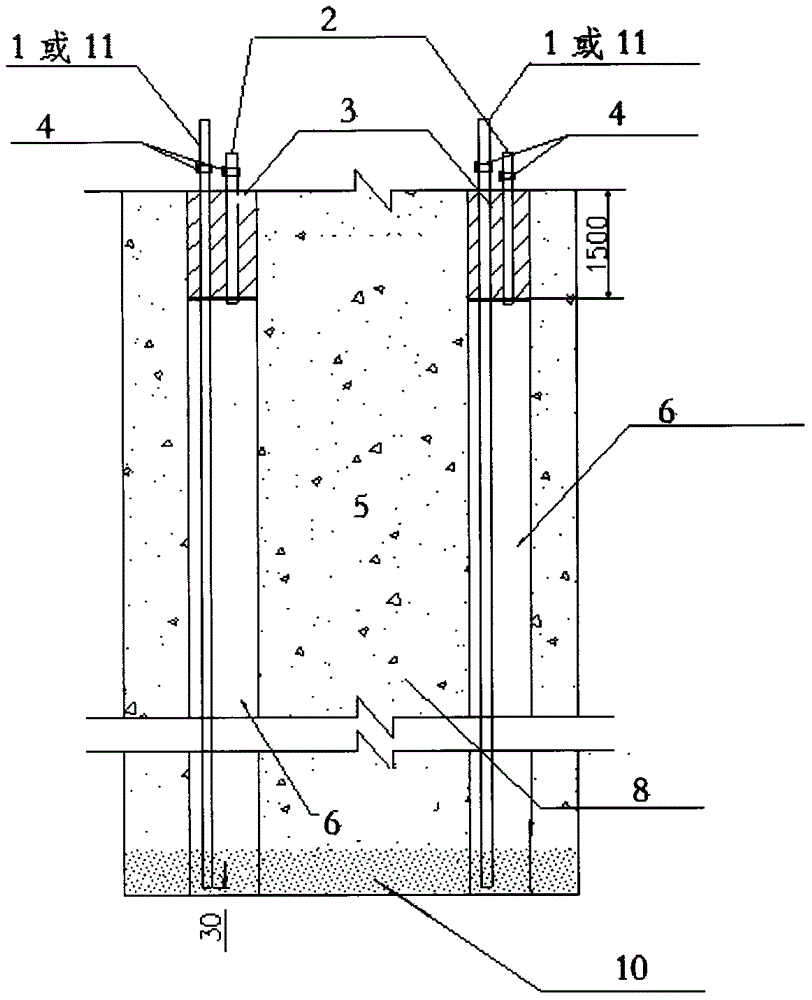

[0017] In the implementation column, the present invention utilizes two interconnected boreholes for judging pile body collapse holes or pile bottom sediment defects, and adopts high-pressure water gas cutting-gas lift slag removal-hole washing-self-compacting atmospheric pressure grouting-high pressure Grouting-The construction method of implanting high-strength rebar in the grouting hole is used to reinforce the collapsed hole of the pile body or the sediment defect at the bottom of the pile. Specifically, high-pressure water gas is used to high-pressure cut the soil clods or sediments in the pile body collapse holes or pile bottom sediment defects, and the soil clods or sediments are chipped and broken, and the sand particles at the defects are removed by air lift. , clay, and silt are cleaned out of the pile, and then high-grade cement is used to prepare cement slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com