Gas percussion hot wind and vacuum pulsating vacuum combination drying method and device

A combined drying and vacuum pulsation technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying solid materials, etc., can solve the problem of unscientific hot air circulation, poor convective heat transfer effect of hot air, and unreasonable exhaust gas discharge, etc. problems, to achieve the effect of shortening drying time, reducing drying energy consumption, and broadening the path of material moisture transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

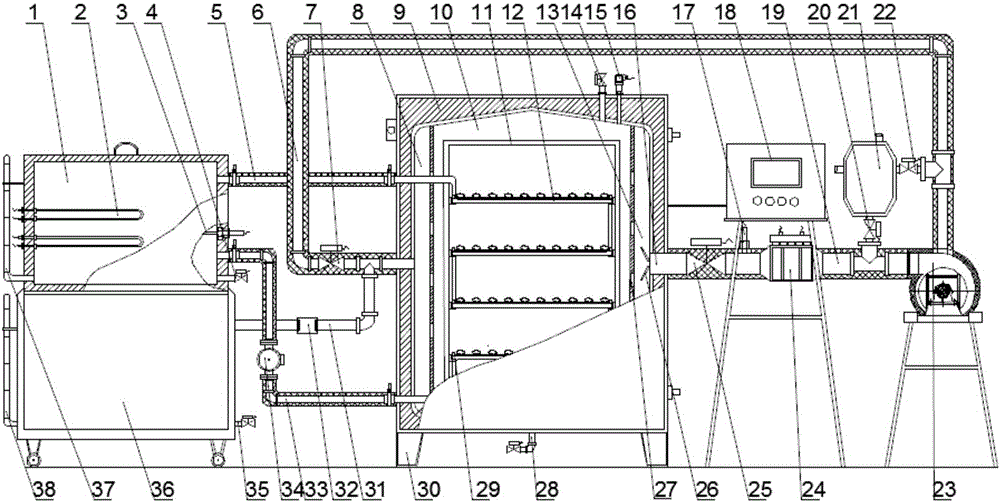

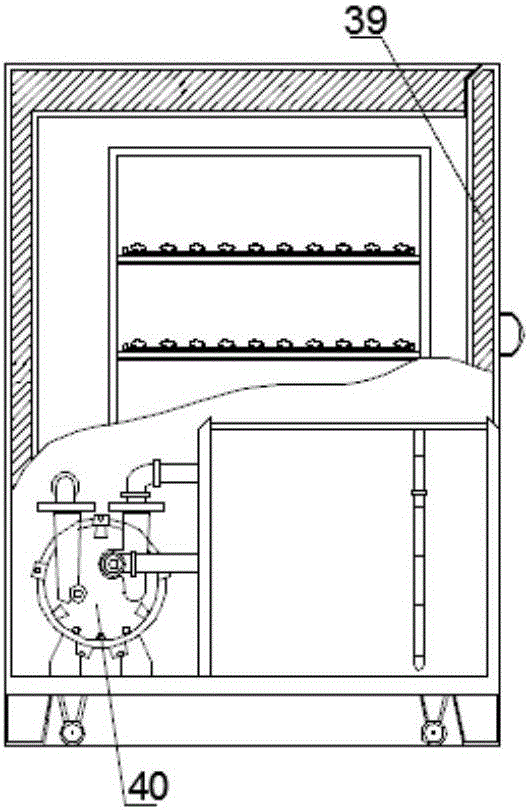

[0041] The invention will be further described below with reference to the accompanying drawings and specific embodiments. The following examples are descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0042] A combined drying method of airflow impact and vacuum pulsation, the technical scheme includes:

[0043] (1) The hot air drying stage of the hot air vacuum combined drying adopts the gas jet impingement technology, which is characterized in that the airflow velocity of the airflow jet port is 0~20m / s. Improve convective heat transfer coefficient and heat transfer efficiency;

[0044] (2) The hot air drying stage of the hot air vacuum combined drying adopts the humidity control and dehumidification technology, and it is characterized in that the intermittent automatic dehumidification in the drying process is carried out based on the upper and lower limits of the set humidity and the humidity of the drying chamber monitored onlin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com