Treatment device and method for flue gas of rare earth kiln

A flue gas treatment and treatment device technology, which is applied in the field of rare earth furnace flue gas, can solve the problems of increased production costs, waste of water resources and heat, etc., and achieve the effects of improving utilization, not easy to scale, and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

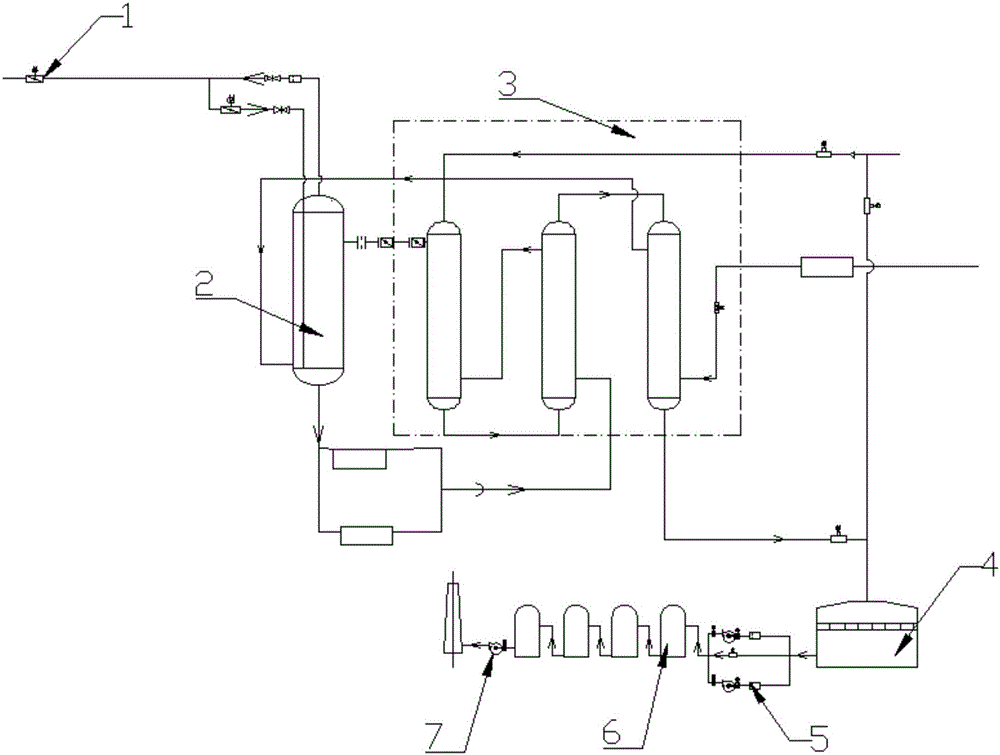

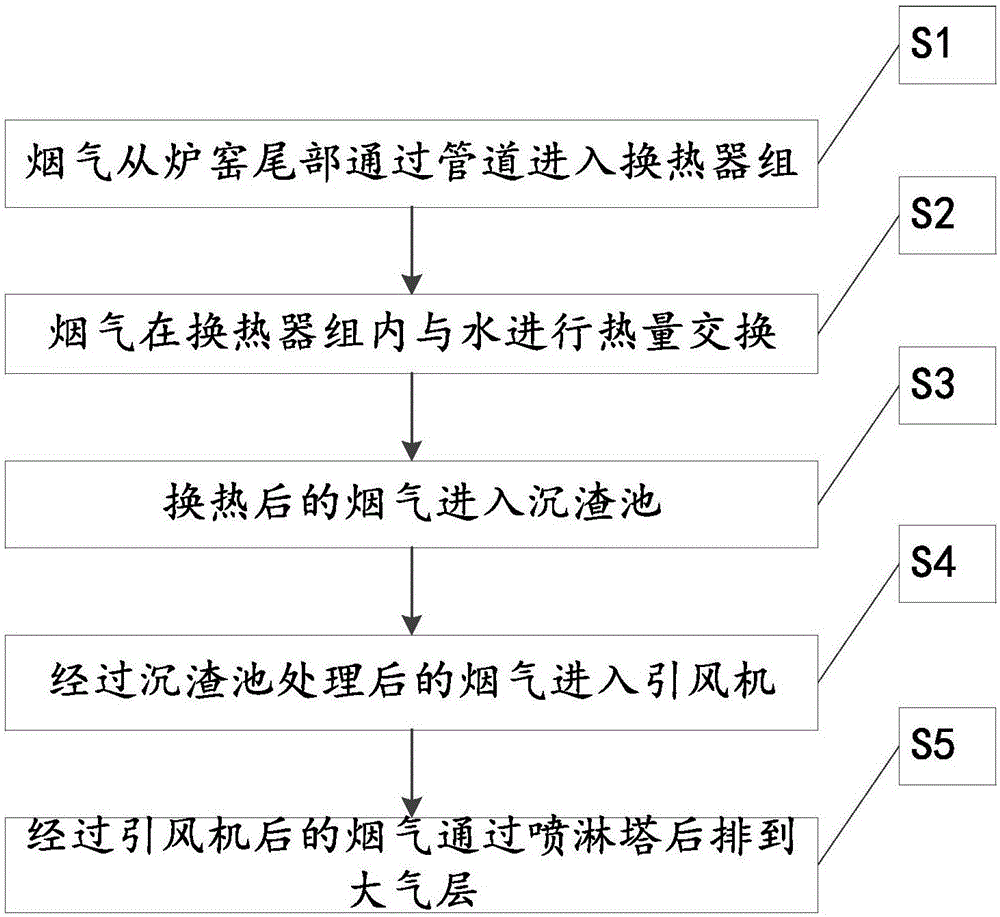

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0033] Such as figure 1 and 2 As shown, after the flue gas comes out from the tail of the kiln, a large amount of sulfur, fluorine, strong acid flue gas and radioactive waste residue are produced during the high-temperature roasting process. The washing of the spray tower can remove the acidic substances and waste residues from the flue gas, and the flue gas that meets the emission requirements is discharged into the atmosphere through the induced draft fan 5 and the chimney, but the temperature of the flue gas is reduced from 350 ° C to 60 ° C with the sediment and water washing. ℃, this part of the heat is taken away by the cooling water, which is wasted in vain. At the same time, a large amount of cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com