Label, system and application method for measuring surface strain of metal component

A metal component and metal surface technology, which is applied in the field of strain measurement on the surface of metal components, can solve problems such as complex operations, power supply failure, and numerous leads, and achieve the effect of not being easily damaged, relaxing processing restrictions, and firm strain sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

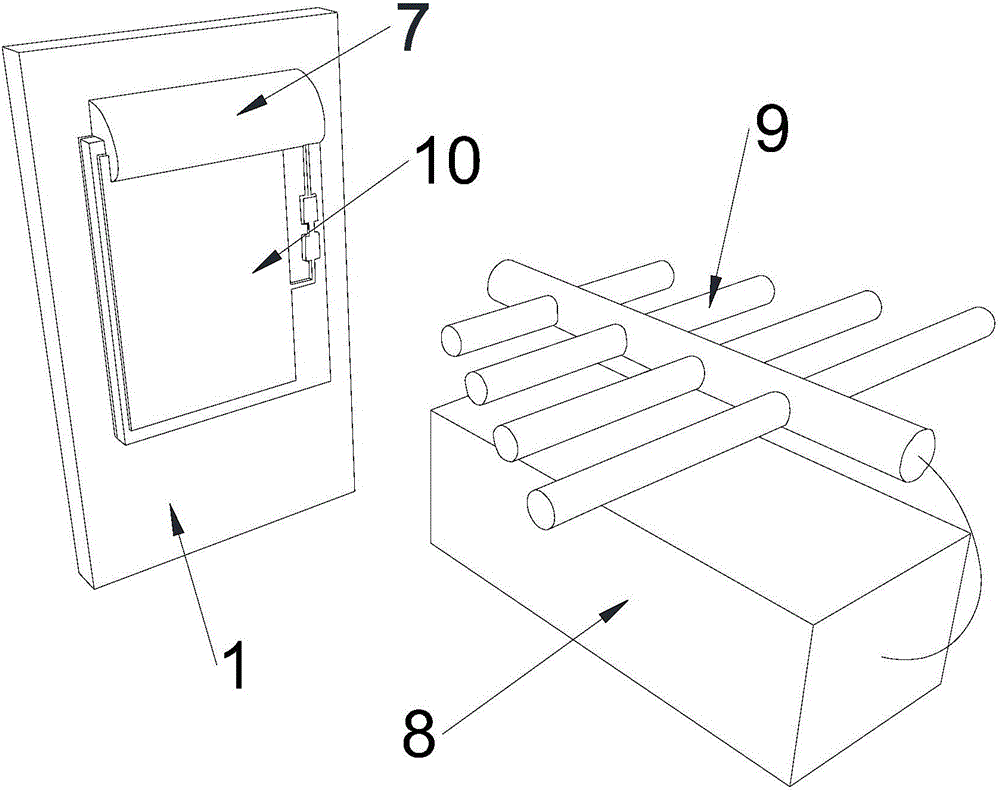

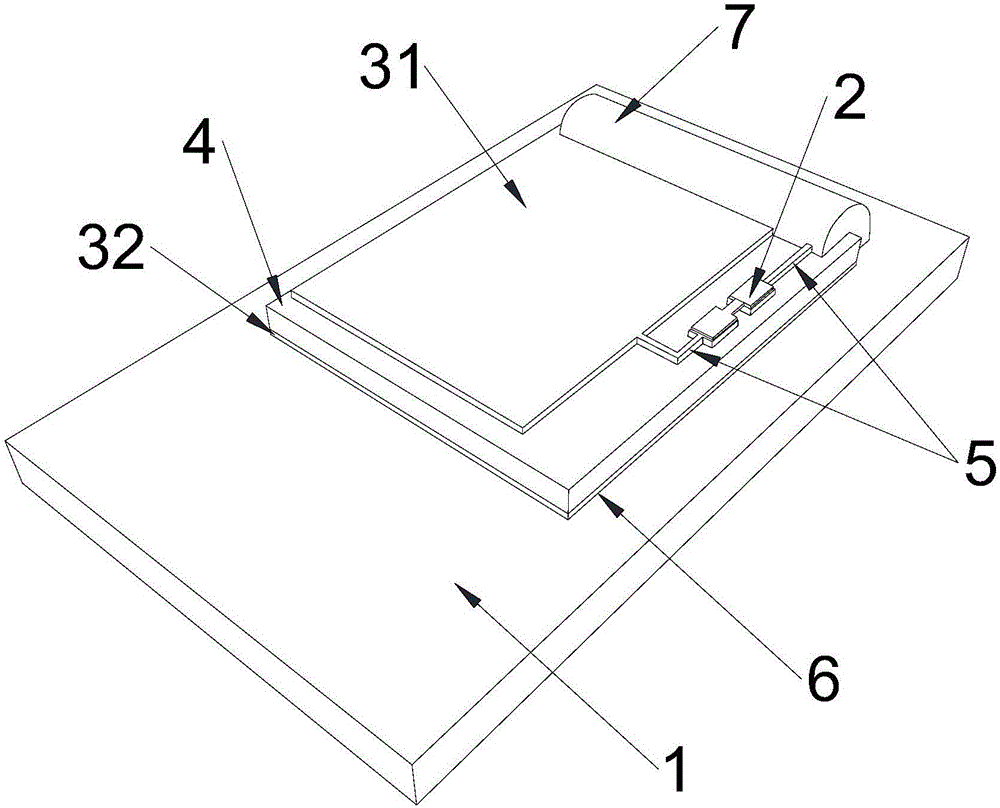

[0037] The system of the present invention is composed of RFID tags and RFID readers. The RFID tag is pasted on the surface of the metal component under test with conductive glue. In the RFID tag, a quarter-wavelength rectangular patch antenna short-circuited through the weld is used as the sensing unit. When the surface of the metal component under test undergoes strain, the patch The change of the antenna size causes the resonant frequency to drift; the code information of the tag is carried in the chip, and the RFID reader is used to transmit the modulated electromagnetic wave signal to the tag, and the code of the tag can be identified. When multiple RFID tags are arranged in the scanning range of the RFID reader, the reading The device can mark the strain value of each measuring point according to the code of each label.

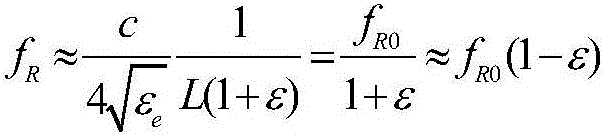

[0038] The RFID used in this system is specially designed, and its principle of measuring the surface strain of metal components is as follows: the RFI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com