Large-aperture aspheric online contour detection device and detection method thereof

A technology of contour detection and detection method, which is applied in the field of optical detection, can solve the problems of limiting the measurement accuracy of three-coordinate profilers, increasing displacement positioning errors, and greatly affecting detection accuracy, achieving long measurement time, improving measurement accuracy, and principle simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

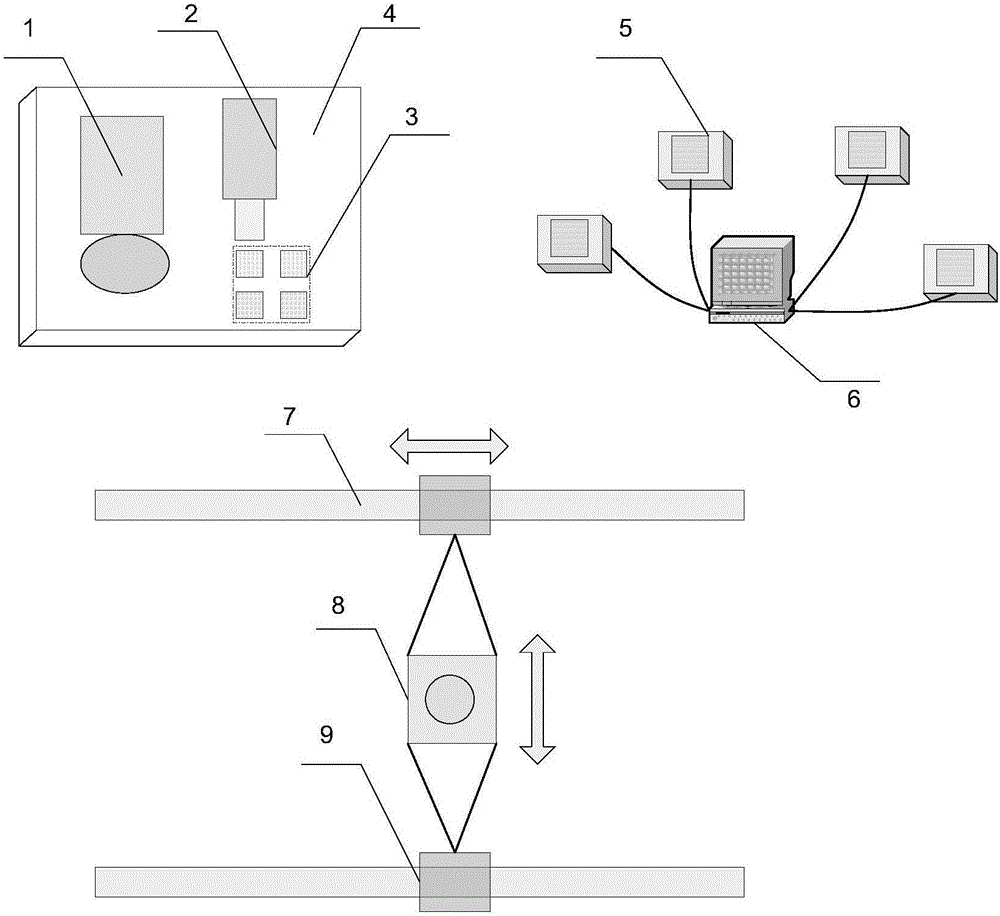

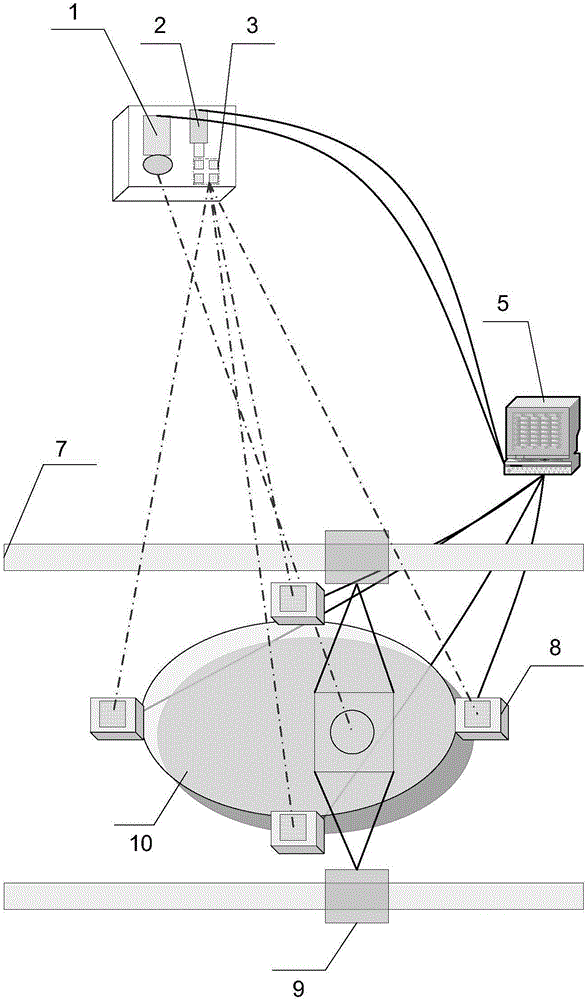

[0036] Embodiment 1, large aperture aspheric surface online profile detection device, such as figure 1 As shown, it includes a laser tracker 1, a laser emitting mechanism, a CCD component 5, a central controller 6, a translation mechanism, and a target ball;

[0037] The CCD assembly includes a plurality of CCDs, and the plurality of CCDs are uniformly and symmetrically fixedly installed on the edge of the mirror under test; in this embodiment, the number of CCDs in the CCD assembly is 4 and can be evenly distributed around the mirror under test.

[0038] The multiple laser beams emitted by the laser emitting mechanism are respectively projected into each CCD in one-to-one correspondence; in this embodiment, such as figure 2 As shown, the laser output mechanism includes a laser 2, a beam splitter and a deflection mirror group 3; the laser light emitted by the laser 2 is divided into laser beams with the same number of CCDs in the CCD assembly through the beam splitter 3, and ...

Embodiment 2

[0043] Embodiment 2, a detection method of a large-diameter aspheric surface online profile detection device, using the large-diameter aspheric surface online profile detection device as in Example 1, the detection process specifically includes the following steps:

[0044] Step 1: select the mirror body benchmark on the mirror under test 10, adopt the laser tracker 1 to measure the mirror body benchmark of the mirror under test 10, and establish the measurement coordinate system of the mirror under test 10 according to the mirror body benchmark; in this embodiment , the mirror body reference is the side milling cylinder or facet of the mirror 9 .

[0045] Step 2: according to the measurement coordinate system, construct a sampling point set covering the entire mirror 10 under test;

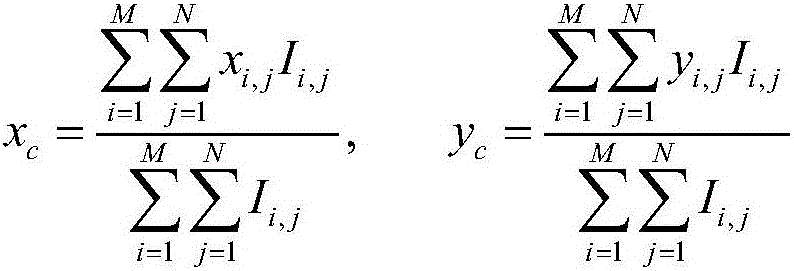

[0046] Step 3: According to the set of sampling points, use the translation mechanism to move the target ball, stop when the target ball reaches the coordinates of a sampling point, trigger the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com