Transient temperature and thermal flux simultaneous measurement sensor and preparation method thereof

A technology of heat flux density and transient temperature, applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve the problem of not being able to measure temperature at the same time, achieve small size, improve sensitivity, and response speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

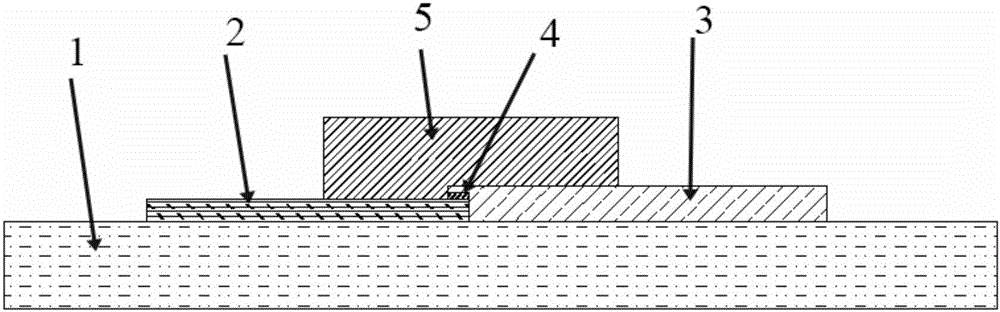

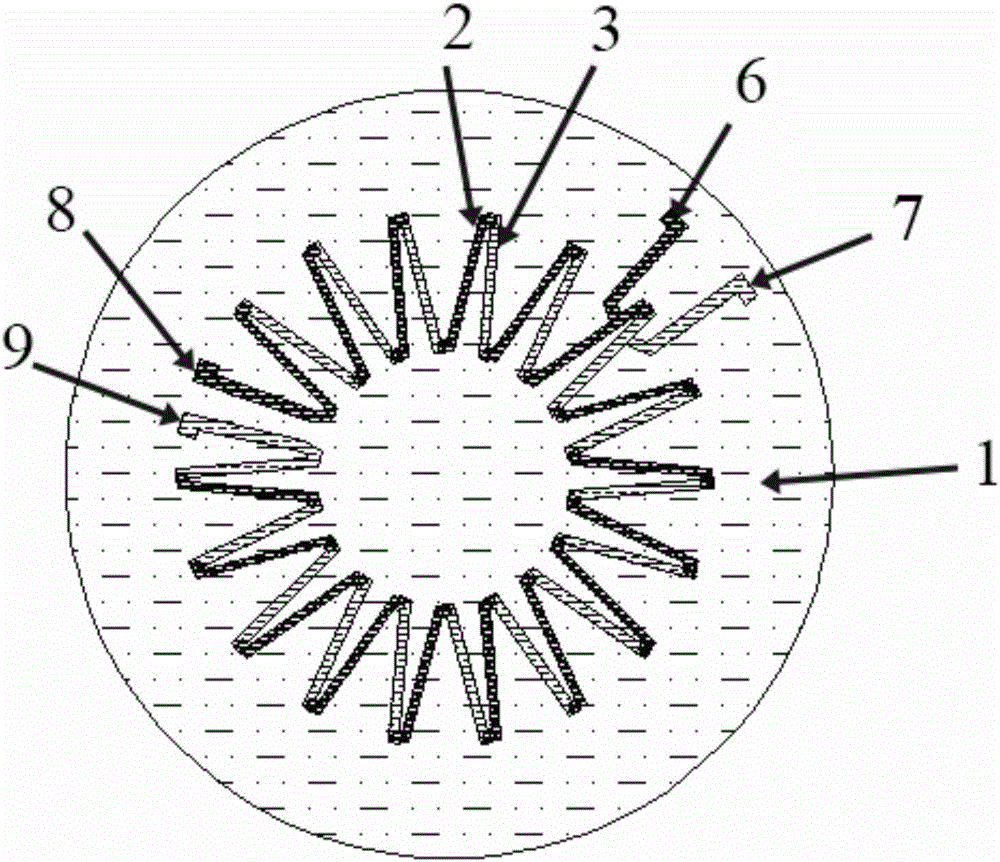

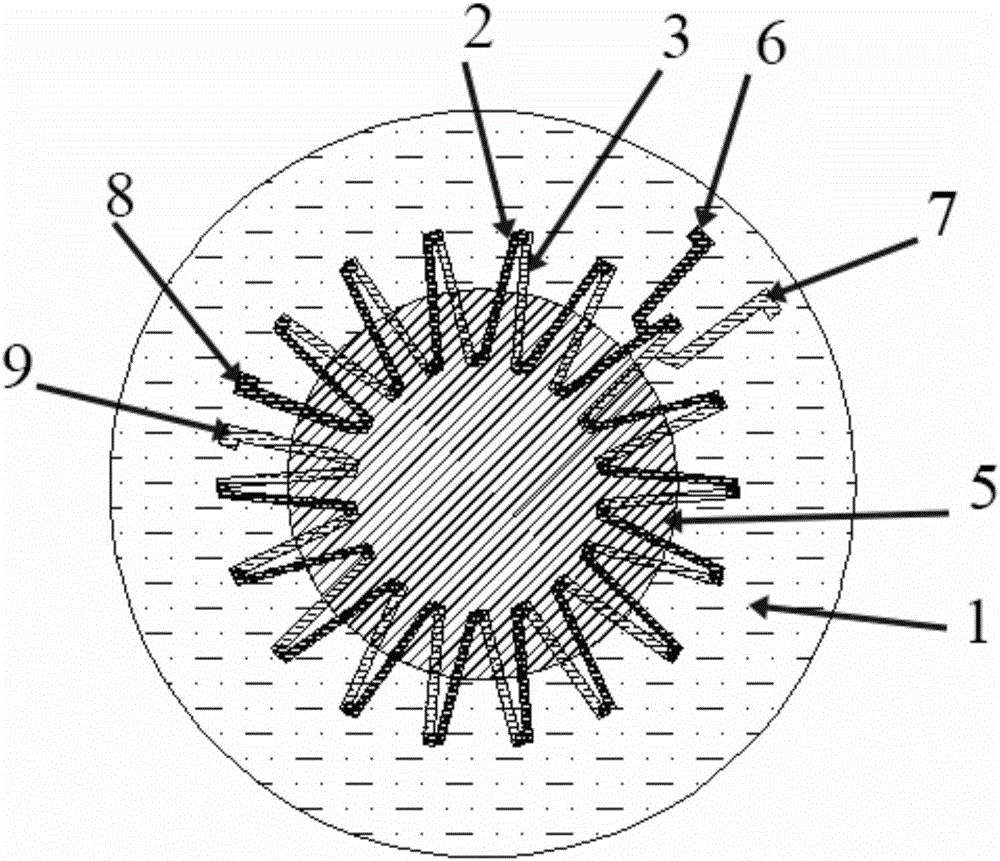

[0040] like figure 1 , figure 2, image 3 As shown, a transient temperature and heat flux joint measurement sensor includes: ceramic substrate 1, positive thermocouple 2, negative thermocouple 3, thermocouple connection layer 4, thermal resistance layer 5, positive thermocouple lead terminal 6, The negative thermocouple terminal 7, the positive thermopile lead terminal 8 and the negative thermopile lead terminal 9, wherein:

[0041] The positive thermocouple 2, the negative thermocouple 3, the thermocouple connection layer 4, the thermal resistance layer 5, the positive thermocouple lead 6, the negative thermocouple 7, the positive thermopile lead 8 and the negative thermopile lead 9 are all It is set on the ceramic substrate 1; the positive thermocouple 2 and the negative thermocouple 3 are butted through the thermocouple connection layer 4; a positive thermocouple 2 and a negative thermocouple 3 are connected in series to form a pair of thermocouples, and multiple pairs o...

Embodiment 2

[0057] A method for preparing a sensor for joint measurement of transient temperature and heat flux, comprising the steps of:

[0058] The first step is to deposit a thin film by magnetron sputtering method, and realize patterning by mask sputtering method or liftoff method, so as to form positive thermocouple 2, positive thermocouple lead end 6 and positive thermopile lead end on ceramic substrate 1 8; where:

[0059] When the thin-film thermopile is a PtRh-Pt type thermocouple, the material of the positive thermocouple 2, the positive thermocouple lead 6 and the positive thermopile lead 8 is platinum rhodium;

[0060] When the thin-film thermopile is a Pt / ITO type thermocouple, the material of the positive thermocouple 2, the positive thermocouple lead 6 and the positive thermopile lead 8 is Pt;

[0061] In the second step, a layer of thermocouple connection layer 4 is formed at both ends of the positive thermocouple 2 in the first step by mask sputtering, and the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com