Method and device for measuring working temperature of slow wave structure of helical traveling wave tube

A technology of working temperature and slow wave structure, which is applied in the field of vacuum electronics, can solve the problems of placing it in it, affecting the working state of the traveling wave tube, and affecting the distribution of the electromagnetic field, so as to achieve the requirement of reducing the speed, accurate distribution of working temperature in the tube, and convenient Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

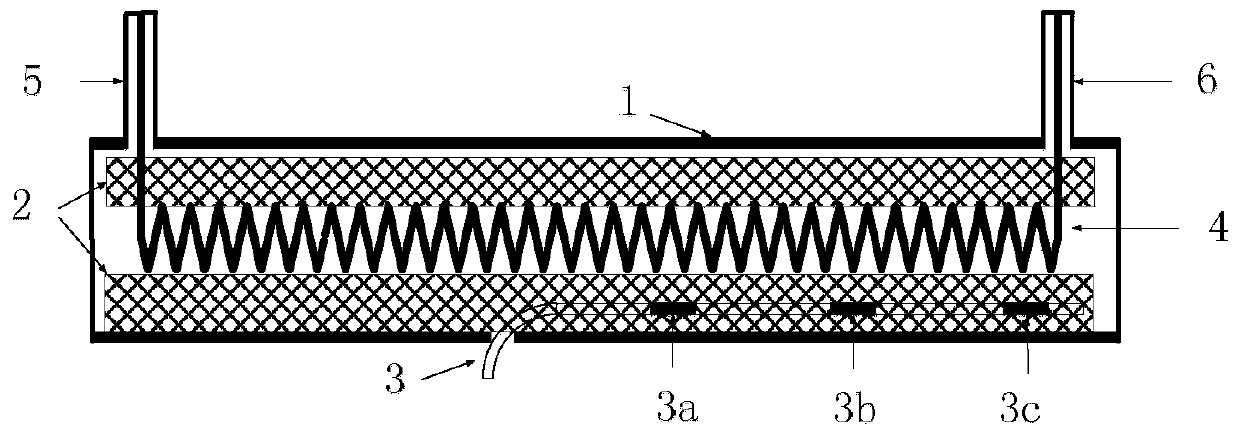

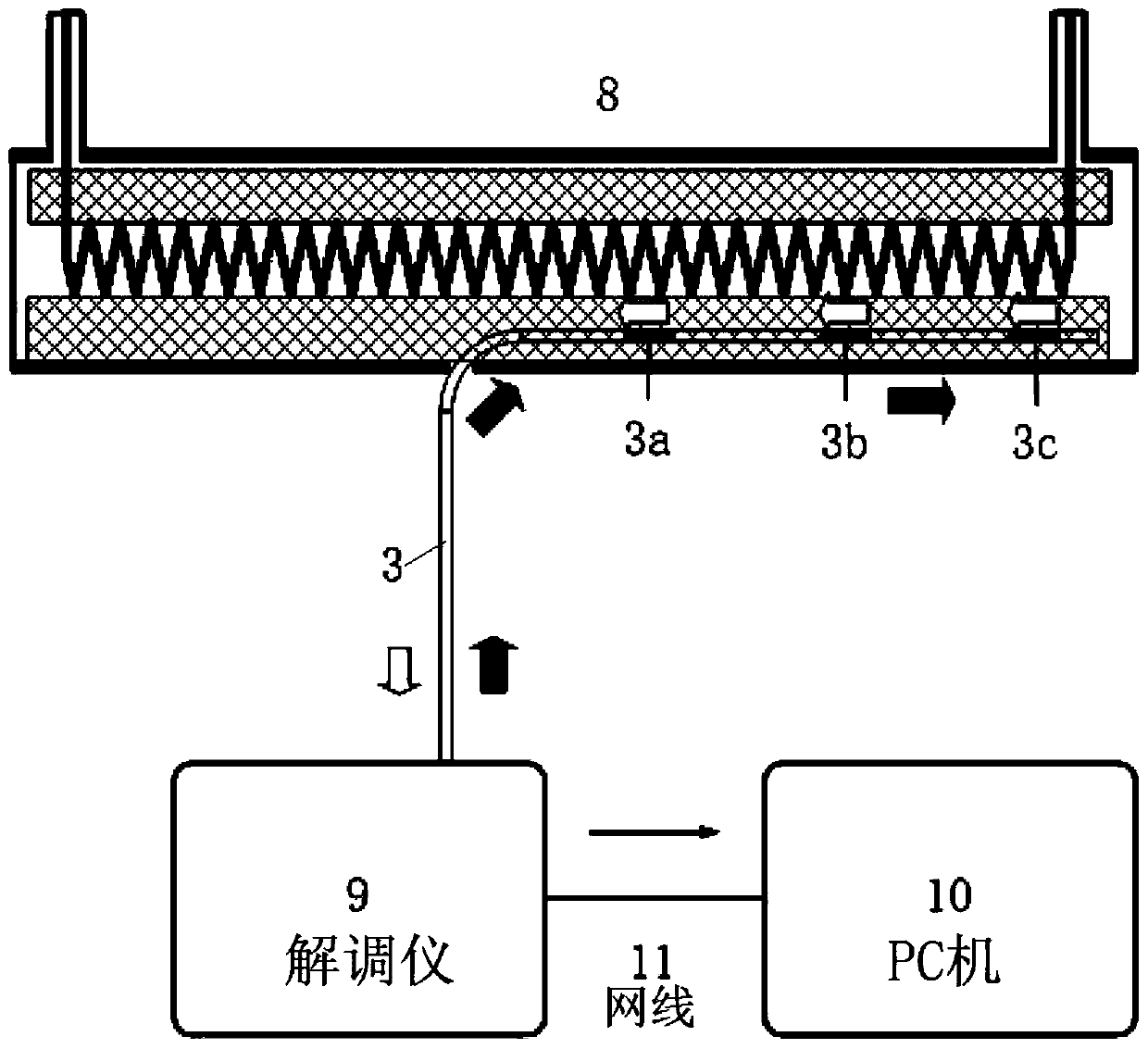

[0046] In the present invention, the traveling wave tube for testing adopts a certain type of 200W traveling wave tube provided by Twelve; the optical fiber adopts the gold-plated optical fiber AS19 / 125 / 155G of FiberGuide Company, the core diameter is 9 μm±0.5 μm, and the cladding diameter is 125 μm+1 / -3μm, the outer armor diameter is 155μm±16μm, the test temperature range is -269 to +700℃; the demodulator adopts the demodulator produced by China Metrology Institute; the data processing device adopts an ordinary desktop computer.

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

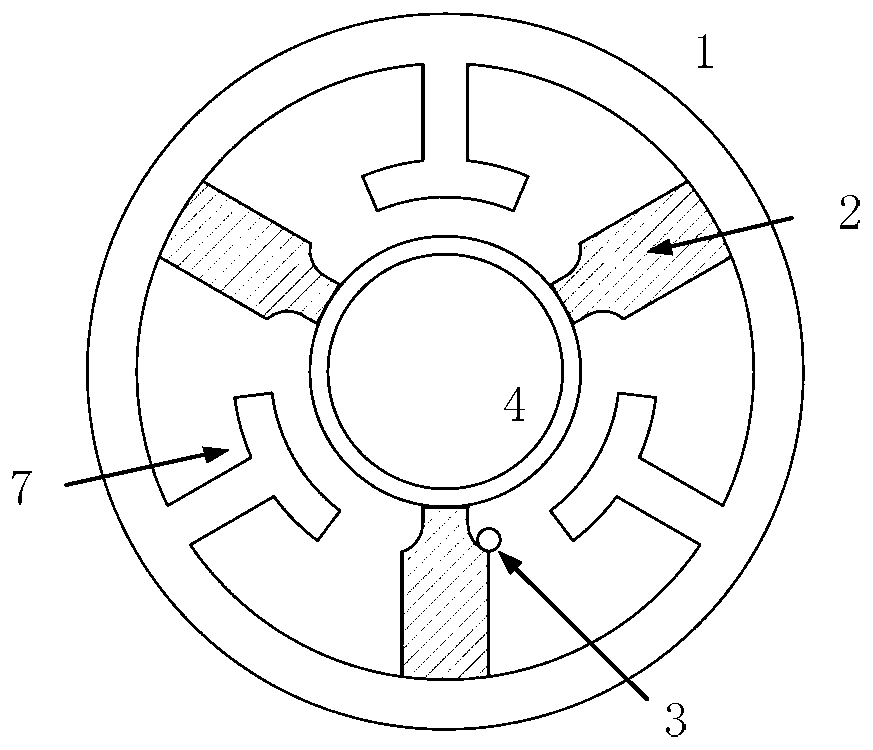

[0048] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com