COA (color-filter on array) substrate

A technology of array substrates and common electrode lines, applied in nonlinear optics, instruments, optics, etc., can solve the problems of accumulation on the periphery of deep holes, affecting product quality, and uneven brightness of products, so as to improve product quality and save equipment renovation and upgrading The cost, the effect of improving the problem of twill mura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

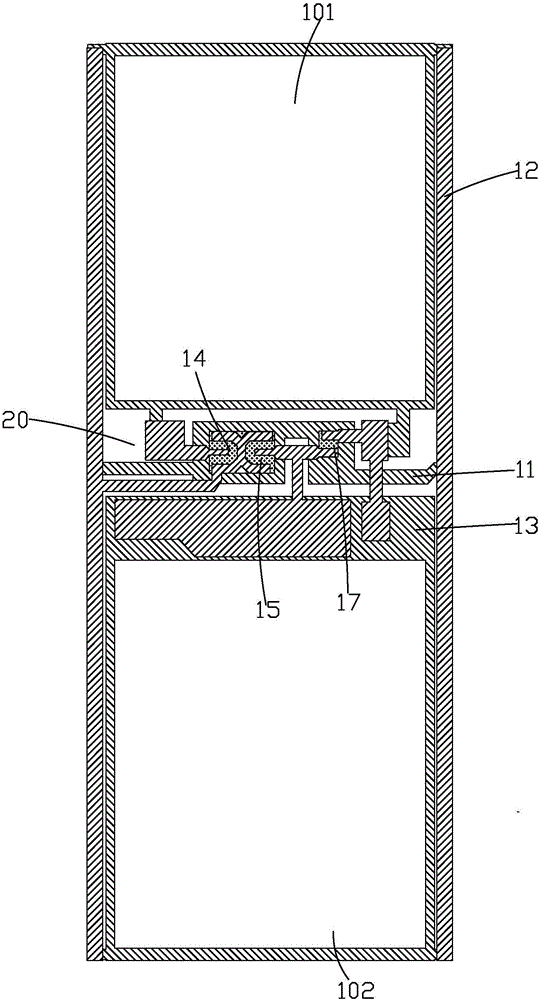

[0039] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

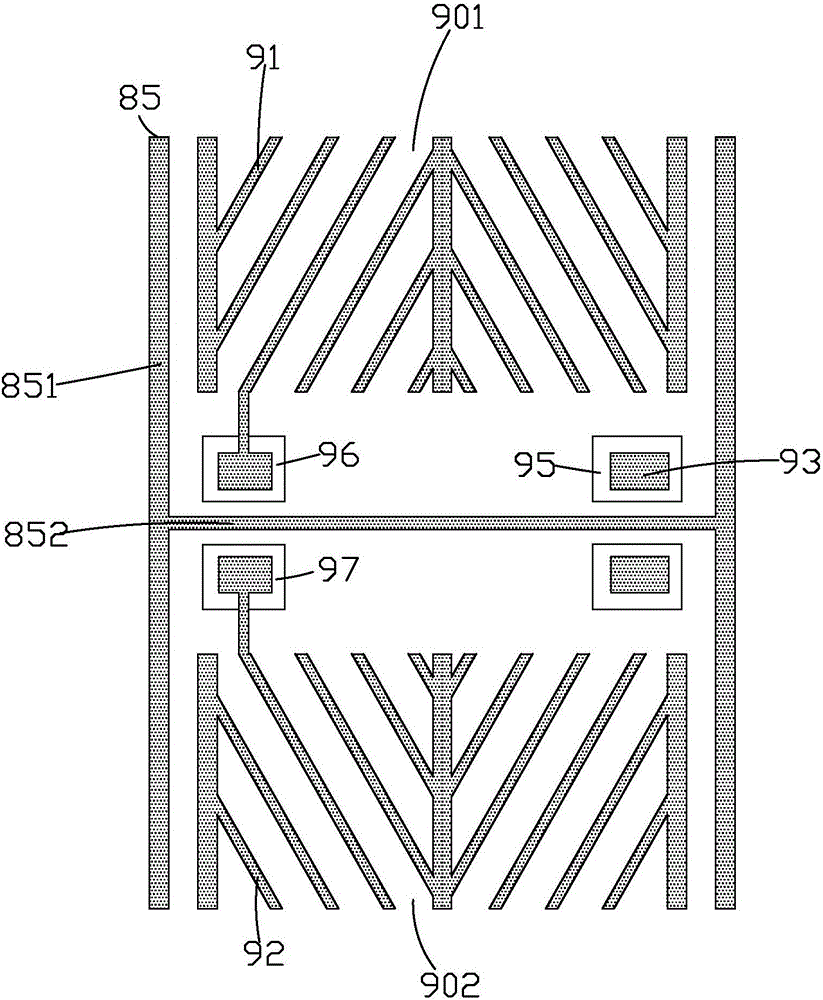

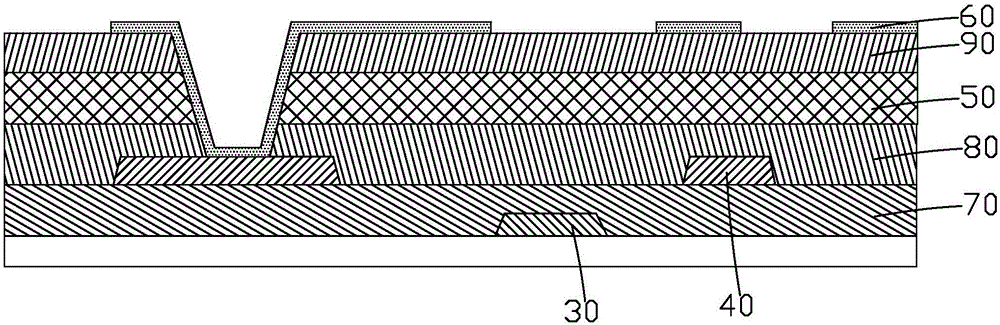

[0040] DBS (that is, Data Line BM Less) pixel design is covered with ITO (that is, indium tin oxide) traces above the data lines. Lines) to form the DBS common electrode lines. When the liquid crystal panel is working normally, the electric field formed by these ITO lines can keep the liquid crystal molecules in a non-deflected state, thereby achieving the purpose of shading, and thus saving the data lines in the liquid crystal panel. The black matrix at the position increases the aperture ratio, so this design is being used more and more.

[0041] Then, for the COA liquid crystal display panel adopting 3T design and DBS design at the same time, on the array substrate, since the DBS common electrode line and the floating ITO in the deep hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com