Coal floatation test demonstration device and method

A technology of floating and sinking test and demonstration device, which is applied in the direction of educational appliances, instruments, teaching models, etc., and can solve the problem that students cannot intuitively observe the phenomenon of coal stratification, test instruments such as heavy liquid buckets with mesh bottoms are bulky, and the key points of test operations Insufficient performance and other problems, to achieve the effect of simple structure, low cost, easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

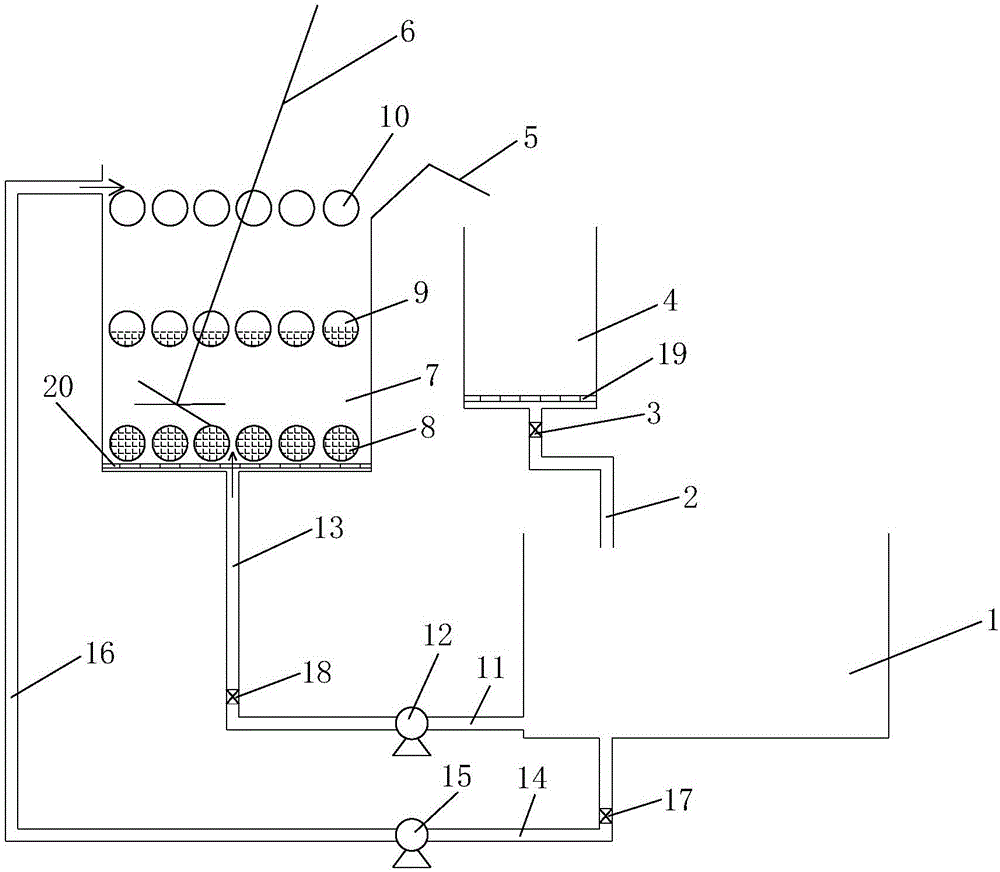

[0042] Such as figure 1 A kind of coal floating-sinking test demonstration device shown, comprises water tank 1, pulse pump 12, water pump 15 and buoyancy tank 7, and the bottom of described water tank 1 is connected with the water inlet of pulse pump 12 through first pipeline 11, and described pulse The water outlet of the pump 12 is connected to the bottom of the buoyancy tank 7 through the second pipeline 13, the bottom of the water tank 1 is connected to the water inlet of the water pump 15 through the third pipeline 14, and the water outlet of the water pump 15 is connected through the fourth pipe The road 16 is connected to the upper part of the floating sinking tank 7, and the upper part of the floating sinking tank 7 is provided with an overflow weir 5, and the described floating sinking tank 7 is provided with an agitator 6, high-density PVC particles 8, medium-density PVC particles 9 and low-density PVC particles. PVC particles 10, the bottom of the overflow weir 5 i...

Embodiment 2

[0050] combine figure 1 , the present embodiment utilizes the method that the device described in embodiment 1 carries out the coal float-sink test demonstration and comprises the following steps:

[0051] Step 1. Fill the water tank 1 with water, and feed high-density PVC particles 8, medium-density PVC particles 9 and low-density PVC particles 10 into the buoyancy tank 7;

[0052] Step 2, open the upflow check valve 18, start the pulse pump 12, feed the water in the water tank 1 into the floating and sinking tank 7, and close the pulse pump 12 when the water reaches the overflow weir 5;

[0053] Step 3: Start the agitator 6, stir at a low speed for 4 minutes, then turn off the agitator 6, and let it stand for 3 minutes, so that the PVC particles of different densities are layered according to the density in the floating sink 7, that is, the low-density PVC particles 10 float in the floating sink 7 The upper layer, medium-density PVC particles 9 are suspended in the middle o...

Embodiment 3

[0058] combine figure 1 , the present embodiment utilizes the method that the device described in embodiment 1 carries out the coal float-sink test demonstration and comprises the following steps:

[0059] Step 1. Fill the water tank 1 with water, and feed high-density PVC particles 8, medium-density PVC particles 9 and low-density PVC particles 10 into the buoyancy tank 7;

[0060] Step 2, open the upflow check valve 18, start the pulse pump 12, feed the water in the water tank 1 into the floating and sinking tank 7, and close the pulse pump 12 when the water reaches the overflow weir 5;

[0061] Step 3: Start the agitator 6, stir at a low speed for 3 minutes, then turn off the agitator 6, and let it stand for 4 minutes, so that the PVC particles of different densities are layered according to the density in the floating sink 7, that is, the low-density PVC particles 10 float in the floating sink 7 The upper layer, medium-density PVC particles 9 are suspended in the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com