Ion-injection-assisting peeling method for ultrathin film material

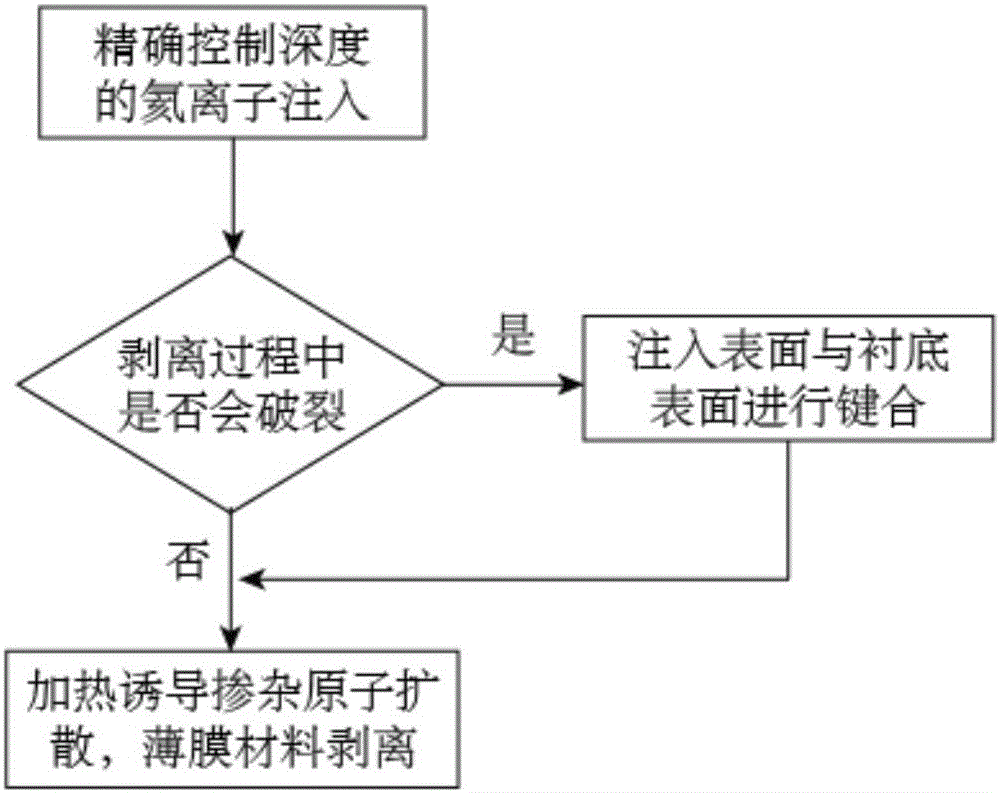

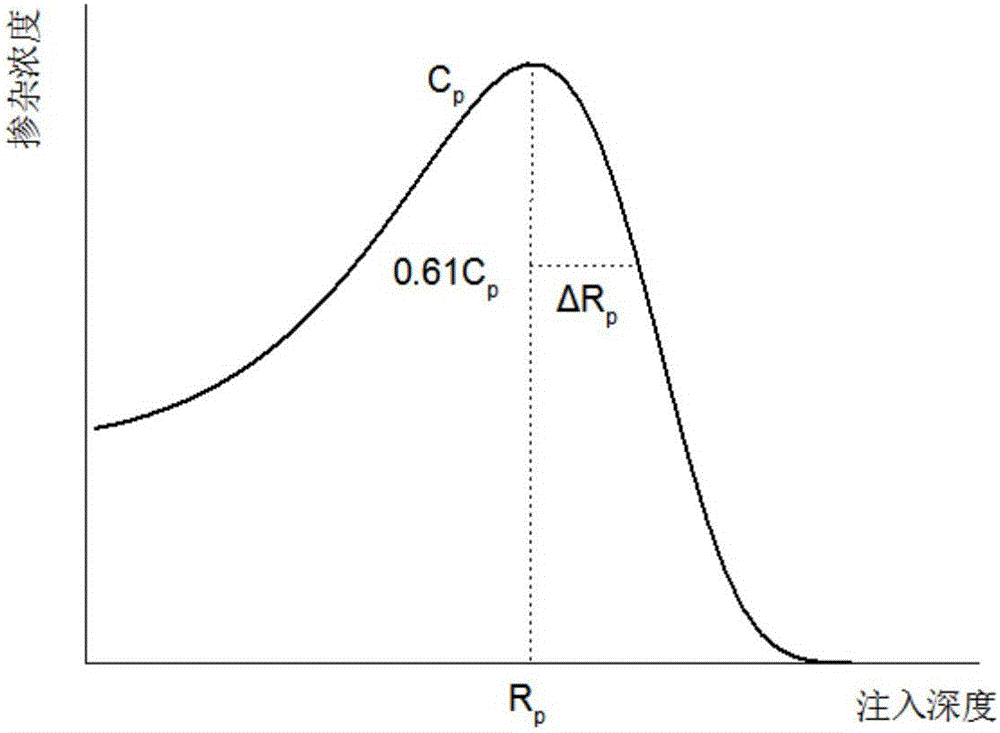

An ion implantation, thin film material technology, applied in electrical components, lamination, semiconductor/solid state device manufacturing, etc., can solve the problem of low repeatability, reduced peeling layer energy, low repeatability of layered material thickness and morphology, etc. problem, to achieve the effect of strong uniformity, maintaining the lattice structure, and maintaining the uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Ion implantation assisted exfoliation of 1 to 10 graphene atomic layers.

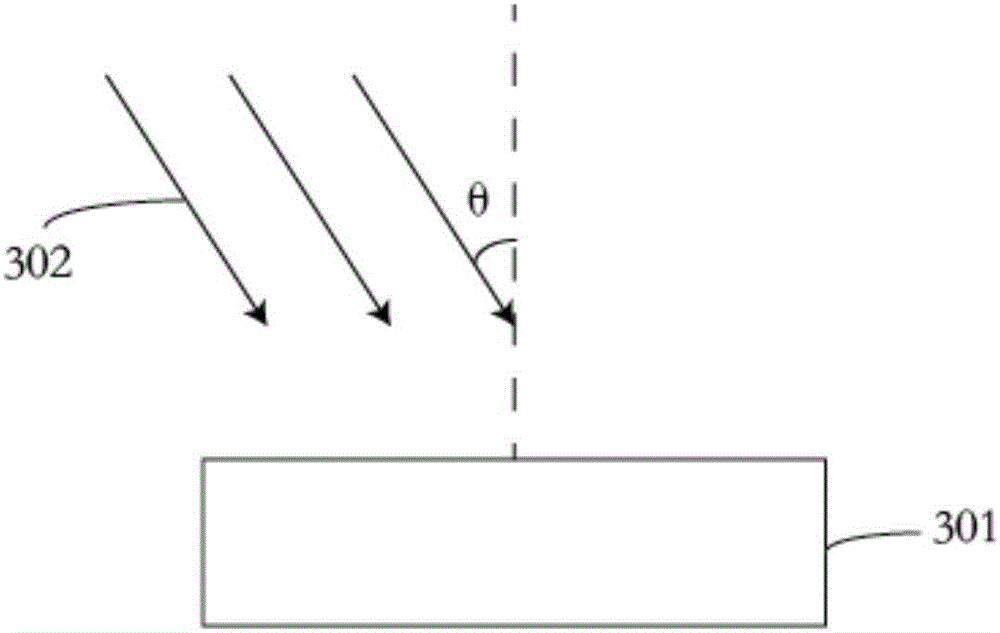

[0057] Step 1: Using a thicker graphene material 301 , select a material surface parallel to the arrangement direction of its internal atomic layers to perform ion implantation 302 .

[0058] Wherein, the included angle between the implanted ion beam and the normal direction of the material surface is 5-30°;

[0059] Wherein, the implanted ions are helium ions;

[0060] Wherein, the implanted ion energy is 1-2000eV;

[0061] Among them, the implanted ion dose is 1012cm-2~1015cm-2;

[0062] Step 2: Cover the surface of the material to be stripped with a substrate 501 as a reinforcement layer. The material injection surface and the substrate are activated, and the material injection surface is induced to bond with the substrate under the conditions of elevated temperature and pressure.

[0063] Wherein, the substrate is a polished silicon wafer;

[0064] Wherein, the heating temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com