Middle temperature solid oxide fuel cell electrolyte and preparation method thereof

A solid oxide and fuel cell technology, applied in fuel cells, electrolytes, circuits, etc., can solve the problems of poor battery sealing performance, high requirements for connector materials, and densification of electrodes, so as to achieve improved electrochemical performance and small size , the effect of reducing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

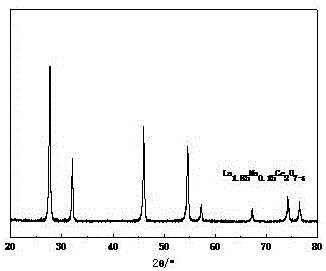

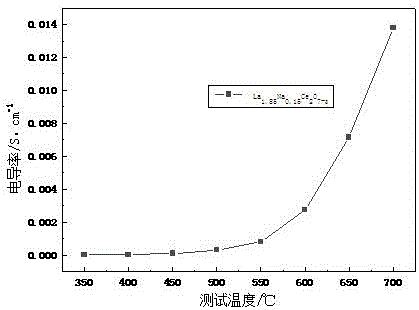

[0032] (1) 1 mole La 1.85 Na 0.15 Ce 2 o 7-δ (LNC) preparation:

[0033] Prepare 0.01mol La1.85 Na 0.15 Ce 2 o 7-δ :

[0034] Weigh 1.85 moles of La(NO 3 ) 3 ·nH 2 O: 1.85×324.92= 601.102 grams;

[0035] Weigh 0.15 moles of NaNO 3 : 0.15×84.99=12.749 grams;

[0036] Weigh 2 moles of Ce(NO 3 ) 3 ·6H 2 O: 2×434.22=868.440 grams;

[0037] Weigh 6 moles of citric acid: 6×210.14=1260.840 grams;

[0038] (2) NaNO 3、 Ce(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 and citric acid were dissolved in deionized water respectively;

[0039] (3) Pour all the above solutions into the citric acid solution, add ammonia water dropwise to adjust the pH value to 7;

[0040] (4) Put the mixed solution into a stirrer and heat it to 70°C, stir continuously at 70°C, and add ammonia water during the stirring process to keep the pH value of the solution at 7 until a gel is formed;

[0041] (5) Move the gel into an evaporating dish and heat it on an electric furnace until self-propagating com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com