Multi-block copolyester, preparation method of the multi-block copolyester and preparation method of compound of multi-block copolyester

A copolyester and multi-block technology, which is applied in the field of multi-block copolyester with ER reaction, can solve the problem that the Diels-Alder bond content of the polyurethane molecular chain cannot be easily adjusted, which limits the adjustability of the final material properties and limits the furan The number of rings and other issues can be improved to improve heat resistance, good repeatability and molding performance, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

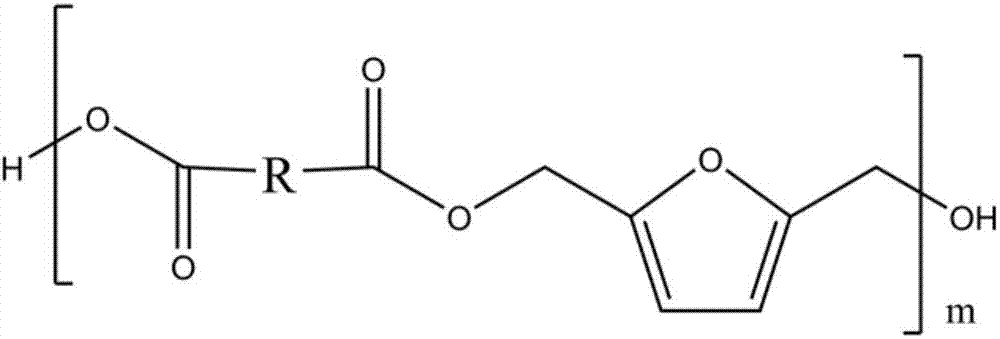

[0045] The preparation method of the multi-block copolyester that the present invention proposes comprises the following steps:

[0046] (1) Solution polymerization:

[0047] (1-1) Evenly mix dibasic alcohol and dibasic acid, wherein, the molar weight of dibasic alcohol is 1.05-1.3 times of dibasic acid molar weight, pass into inert gas protection, add catalyst, the addition amount of catalyst is two 5%-15% of the molar weight of the basic acid, the catalyst is 4-methylaminopyridine, and the stirring is started until the reactants are completely dissolved to obtain the first solution;

[0048] (1-2) In the first solution of the above-mentioned step (1-1), add dehydrating agent in 3-5 times, the addition of dehydrating agent is 100%-200% of dibasic acid molar weight, described dehydrating agent N,N'-dicyclohexylcarbodiimide, N,N'-diisopropylcarbodiimide, N-hydroxysuccinimide, N-hydroxysulfosuccinimide or 1-(3 -One or more of dimethylaminopropyl)-3-ethylcarbodiimide hydrochlor...

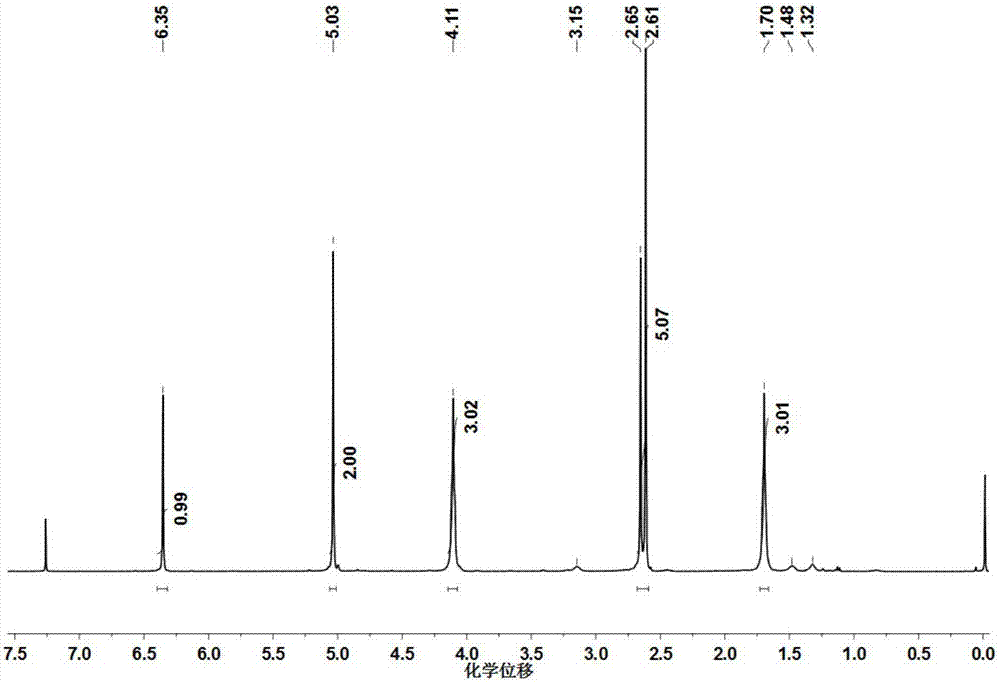

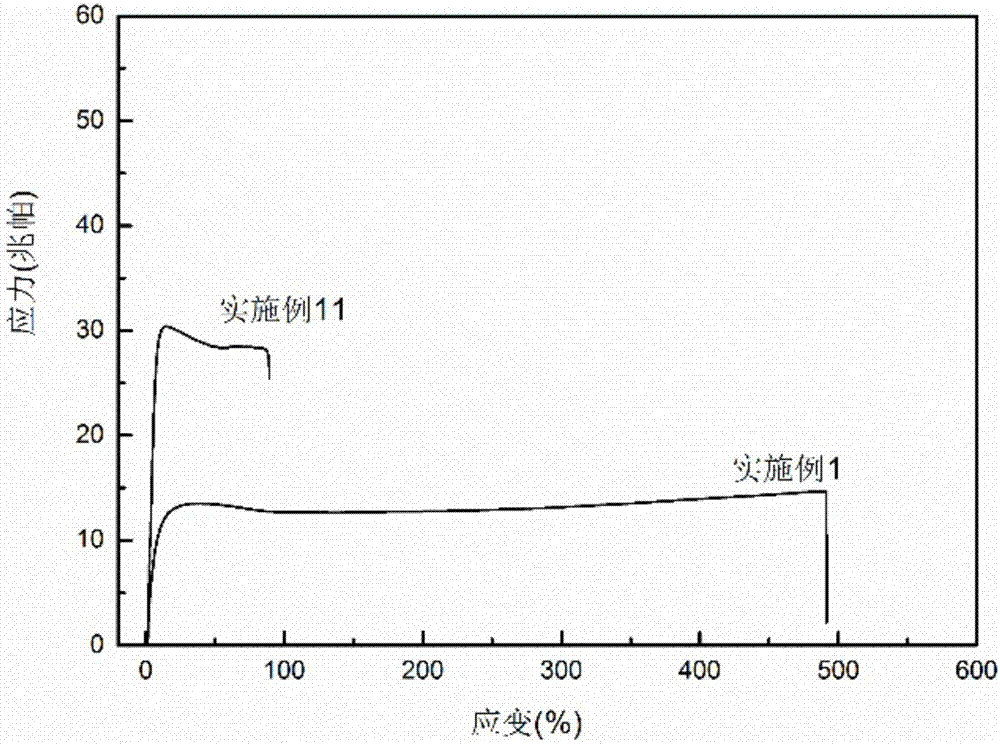

Embodiment 1

[0065] Add 0.4 mol of succinic acid and 0.44 mol of 2,5-furandimethanol into 500 ml of dichloromethane and mix evenly, pass through nitrogen protection, add 0.02 mol of 4-methylaminopyridine as a catalyst, and start stirring until the reactants are completely dissolved. 0.8 mol of dehydrating agent N,N-dicyclohexylcarbodiimide was added to the solution in the above step in four times, and the addition time was 0 hour, 3 hours, 6 hours and 9 hours after the reaction started, and 0.2 mol was added each time. Reaction at normal temperature, the reaction time is 12 hours. Purify to obtain hydroxyl-terminated polysuccinate 2,5-furandimethanol oligomer;

[0066] Add 0.6 mol of succinic acid and 0.66 mol of 1,4-butanediol into 500 ml of dichloromethane and mix evenly, pass through nitrogen protection, add 0.02 mol of 4-methylaminopyridine as a catalyst, and start stirring until the reactants are completely dissolved. 1.2 moles of dehydrating agent N,N-dicyclohexylcarbodiimide was ad...

Embodiment 2

[0069] Add 0.4 moles of terephthalic acid and 0.42 moles of 2,5-furandimethanol into 500 ml of dichloromethane and mix evenly, pass through nitrogen protection, add 0.06 moles of 4-methylaminopyridine as a catalyst, start stirring until the reactants are completely dissolved . Add 0.8 moles of dehydrating agent N,N'-diisopropylcarbodiimide to the solution in the above steps in four times, the addition time is 0 hour, 3 hours, 6 hours and 9 hours after the reaction starts, and add 0.2 moles each time . Reaction at normal temperature, the reaction time is 24 hours. Purify to obtain hydroxyl-terminated poly(2,5-furandimethylene terephthalate) oligomer;

[0070] Add 0.6 mol of terephthalic acid and 0.66 mol of ethylene glycol into 500 ml of dichloromethane and mix evenly, pass through nitrogen protection, add 0.09 mol of 4-methylaminopyridine as a catalyst, and start stirring until the reactants are completely dissolved. Add 1.2 moles of dehydrating agent N,N'-diisopropylcarbod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com