A method for preparing a protective coating on the surface of a plasma etching chamber

A protective coating and plasma technology is applied in the field of preparation of protective coatings on the surface of ion etching chambers, which can solve the problems of unusable polymers, reduced quality of finished wafers, plasma pollution, etc., and achieves enhanced mechanical properties and chemical properties. Stability, maintain structural stability, improve the effect of anti-degeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

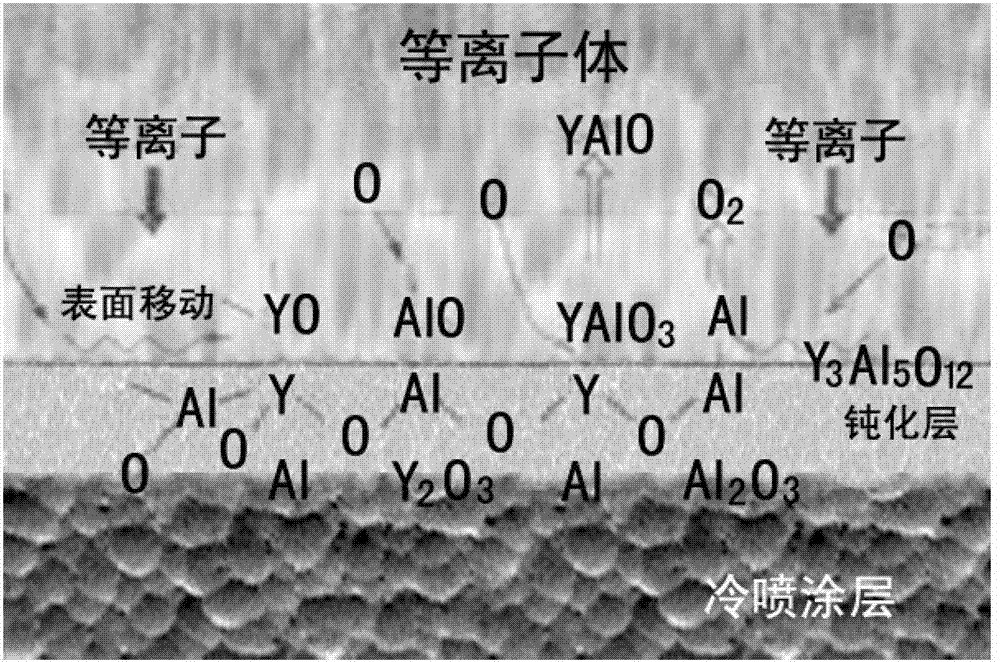

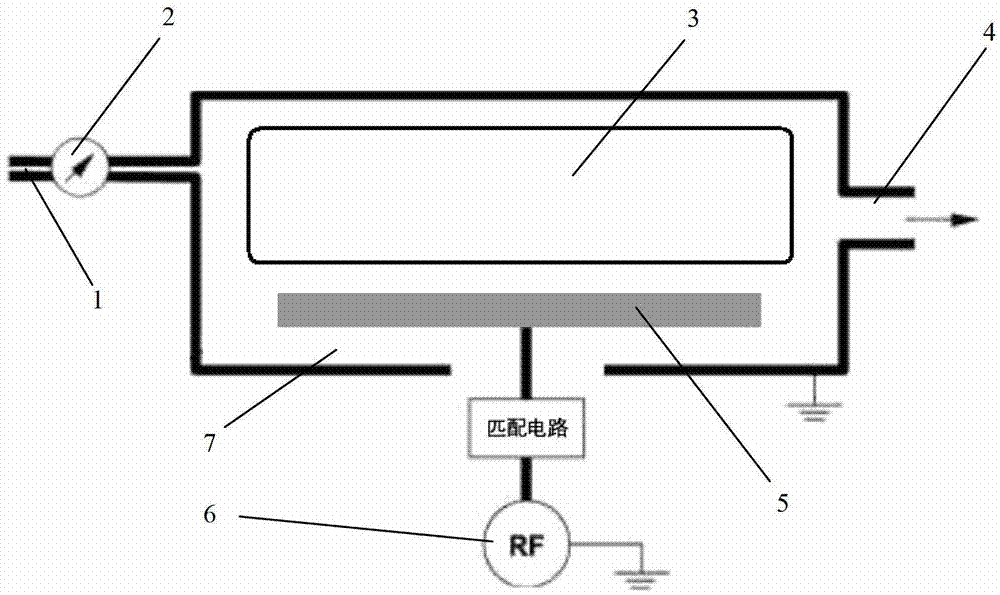

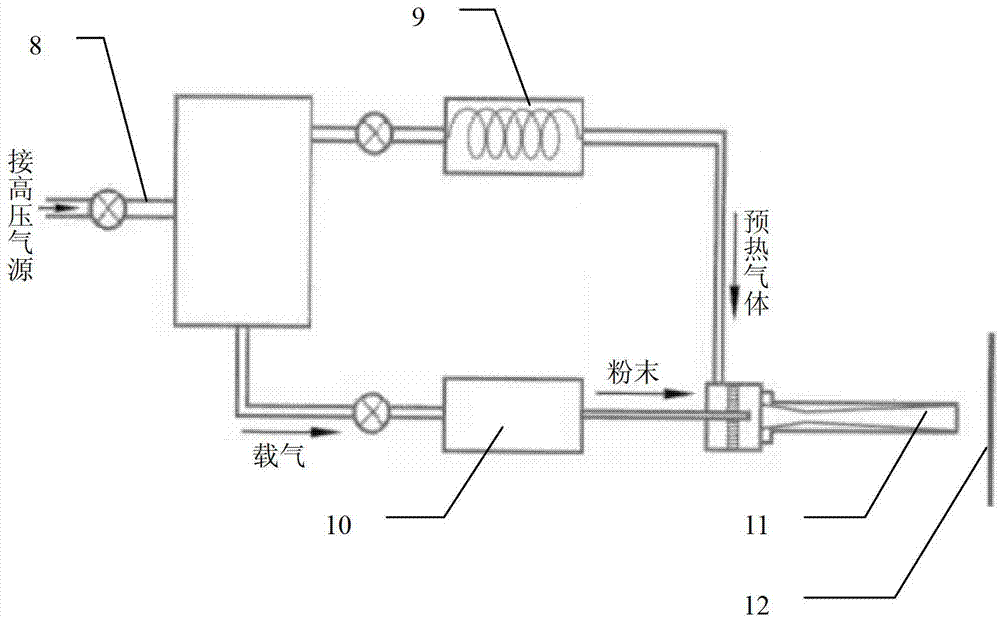

[0048] Using pure Al powder and Y 2 o 3 -A1 2 o 3 The mixed powder of the powder prepares the protective coating on the surface of the plasma etching chamber, and the Al powder and the Y 2 o 3 -A1 2 o 3 The mixed powder of the powder is directly sprayed on the surface of the ion etching chamber. By controlling the spraying parameters: the spray distance is 20mm, the gas pressure is 2.0MPa, the gas temperature is 400°C, the air flow rate is 20g / s, and the average particle size of the powder is 20μm. Deposited on the surface of the plasma etching chamber to form a uniformly distributed protective coating; among them, pure Al powder and Y 2 o 3 -A1 2 o 3 The weight ratio of powder is 0.2:1; Y 2 o 3 -A1 2 o 3 In powder, Y 2 o 3 with A1 2 o 3 The weight ratio is 2:1.

[0049] In this embodiment, the passivation process of the plasma etching chamber refers to the plasma etching process, and the passivation process conditions are as follows,

[0050] (1) Time param...

Embodiment 2

[0065] The difference from Example 1 is that

[0066] Using pure Al powder and Y 2 o 3 -A1 2 o 3 The mixed powder of the powder prepares the protective coating on the surface of the plasma etching chamber, and the Al powder and the Y 2 o 3 -A1 2 o 3 The mixed powder of the powder is directly sprayed on the surface of the ion etching chamber. By controlling the spraying parameters: the spray distance is 5mm, the gas pressure is 1.0MPa, the gas temperature is 300°C, the air flow rate is 10g / s, and the average particle size of the powder is 5μm. Deposited on the inner surface of the plasma etching chamber to form a uniformly distributed protective coating; among them, pure Al powder and Y 2 o 3 -A1 2 o 3 The weight ratio of powder is 0.6:1; Y 2 o 3 -A1 2 o 3 In powder, Y 2 o 3 with A1 2 o 3 The weight ratio is 2.2:1.

[0067] In this embodiment, doped Y 3 A1 5 o 12 thin film, doped Y 3 A1 5 o 12 film, Y 3 A1 5 o 12 Accounting for 95wt%, the rest is Y ...

Embodiment 3

[0069] The difference from Example 1 is that

[0070] Using pure Al powder and Y 2 o 3 -A1 2 o 3 The mixed powder of the powder prepares the protective coating on the surface of the plasma etching chamber, and the Al powder and the Y 2 o 3 -A1 2 o 3 The mixed powder of the powder is directly sprayed on the surface of the ion etching chamber. By controlling the spraying parameters: the spray distance is 30mm, the gas pressure is 3.0MPa, the gas temperature is 500°C, the air flow rate is 30g / s, and the powder particle size is 30μm, so that the mixed powder is deposited On the inner surface of the plasma etching chamber, a uniformly distributed protective coating is formed; among them, pure Al powder and Y 2 o 3 -A1 2 o 3 The weight ratio of powder is 1:1; Y 2 o 3 -A1 2 o 3 In powder, Y 2 o 3 with A1 2 o 3 The weight ratio is 2.3:1.

[0071] In this embodiment, doped Y 3 A1 5 o 12 thin film, doped Y 3 A1 5 o 12 film, Y 3 A1 5 o 12 Accounting for 98wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com