Method for treating soil organic matter and mercury combined contamination

A technology of complex pollution and organic matter, applied in the field of soil pollution remediation, can solve the problem of mercury not easily volatilized, achieve the effect of strengthening the separation process, efficient in-situ remediation, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

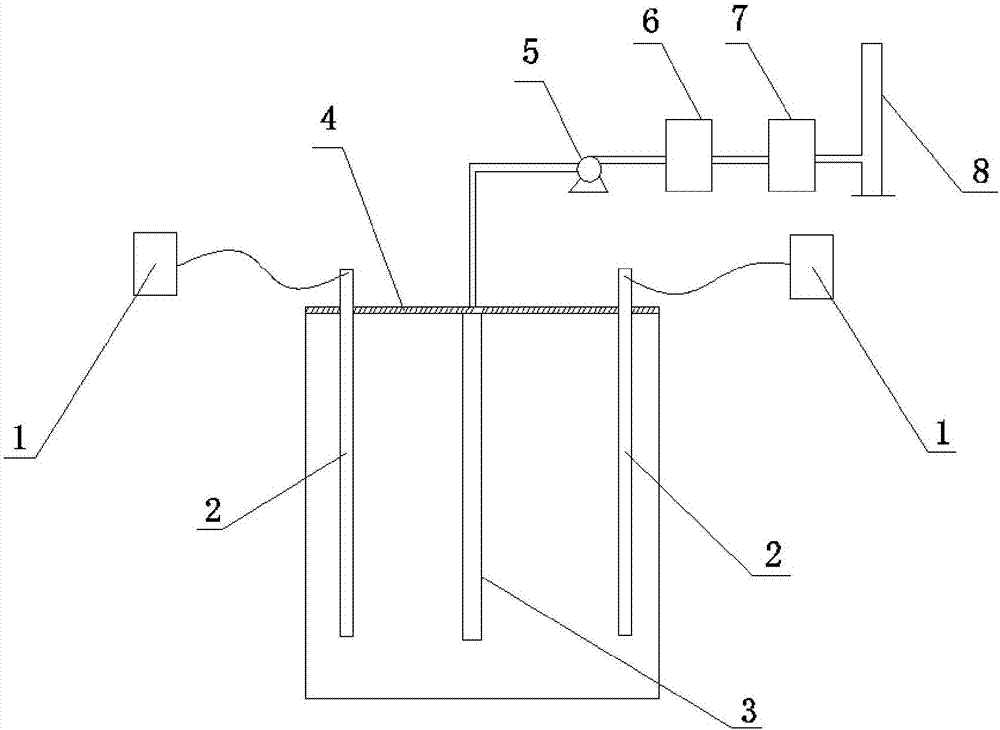

Method used

Image

Examples

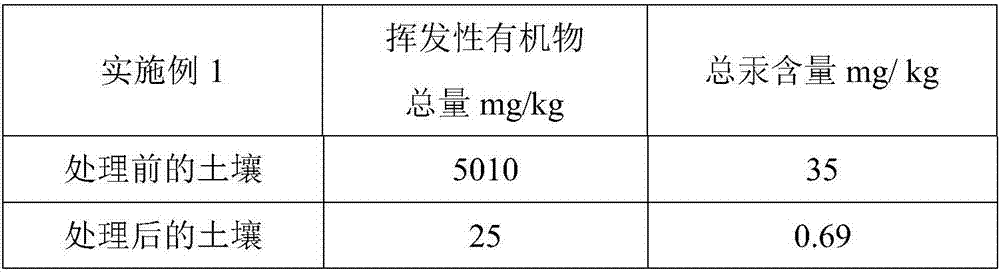

Embodiment 1

[0029] (1), select 5m × 5m of organic matter and mercury composite polluted soil plots, carry out the detection of the total amount of volatile organic compounds and the total mercury content before treatment; remove weeds and stones on the surface of the plots, and compact them with a rolling device to make them The surface of the contaminated soil plot forms a compact level ground;

[0030] (2), adopt low-density polyethylene film to cover described polluted soil plot, then compact with rolling device so that low-density polyethylene film is close to the polluted soil surface;

[0031] (3), drill vertically downwards with a drilling rig in the center of the polluted soil plot to form a cylindrical tunnel with a depth of 15 m and a diameter of 0.2 m; insert a 10 m long, Single-ended heating rod with a diameter of 25mm;

[0032] (4) Connect the cylindrical channel to the vacuum pump, drier, activated carbon adsorber and exhaust cylinder in turn through the pipeline, and conne...

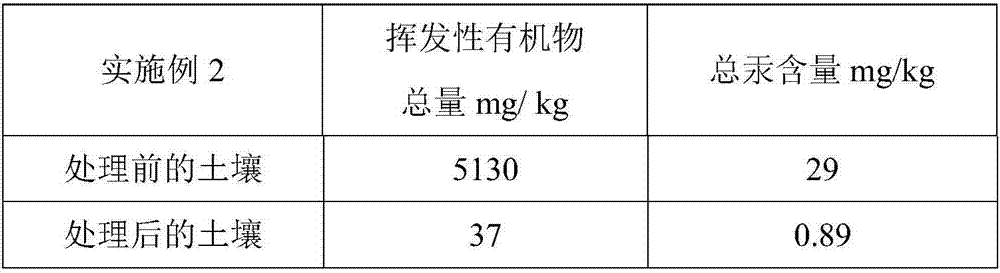

Embodiment 2

[0037] (1), select 5m × 5m of organic matter and mercury composite polluted soil plots, carry out the detection of the total amount of volatile organic compounds and the total mercury content before treatment; remove weeds and stones on the surface of the plots, and compact them with a rolling device to make them The surface of the contaminated soil plot forms a compact level ground;

[0038] (2), adopt low-density polyethylene film to cover described polluted soil plot, then compact with rolling device so that low-density polyethylene film is close to the polluted soil surface;

[0039] (3), in the center of the polluted soil plot, use a drilling rig to drill vertically downwards to form a cylindrical tunnel with a depth of 10m and a diameter of 0.2m; insert a 10m long, Single-ended heating rod with a diameter of 25mm;

[0040] (4) Connect the cylindrical channel to the vacuum pump, dryer, activated carbon adsorber and exhaust cylinder in turn through the pipeline, and conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com