Automatic electric welding machine for closed type circular weld bead

An automatic electric welding, closed technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of unstable welding quality, low degree of automation, environmental and staff hazards, etc., to reduce welding quality and improve welding Quality, the effect of eliminating labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

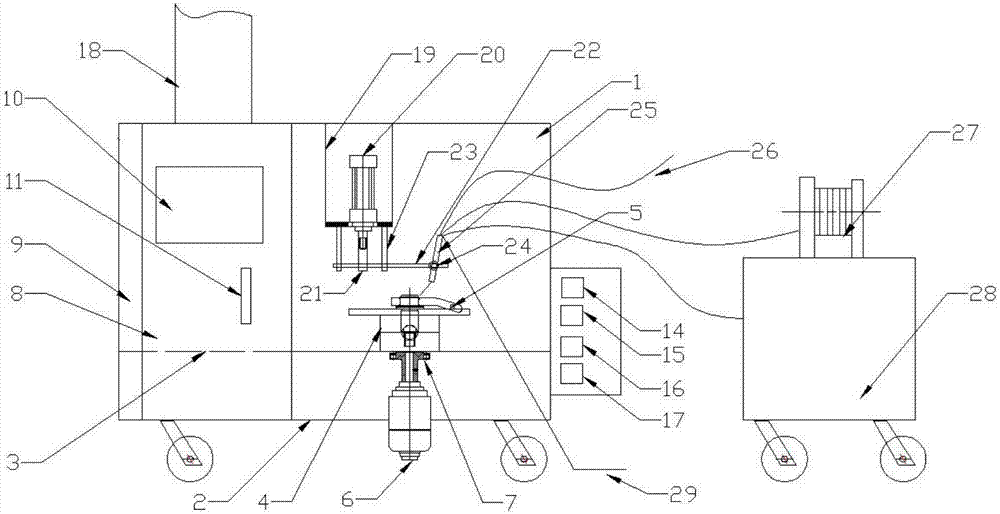

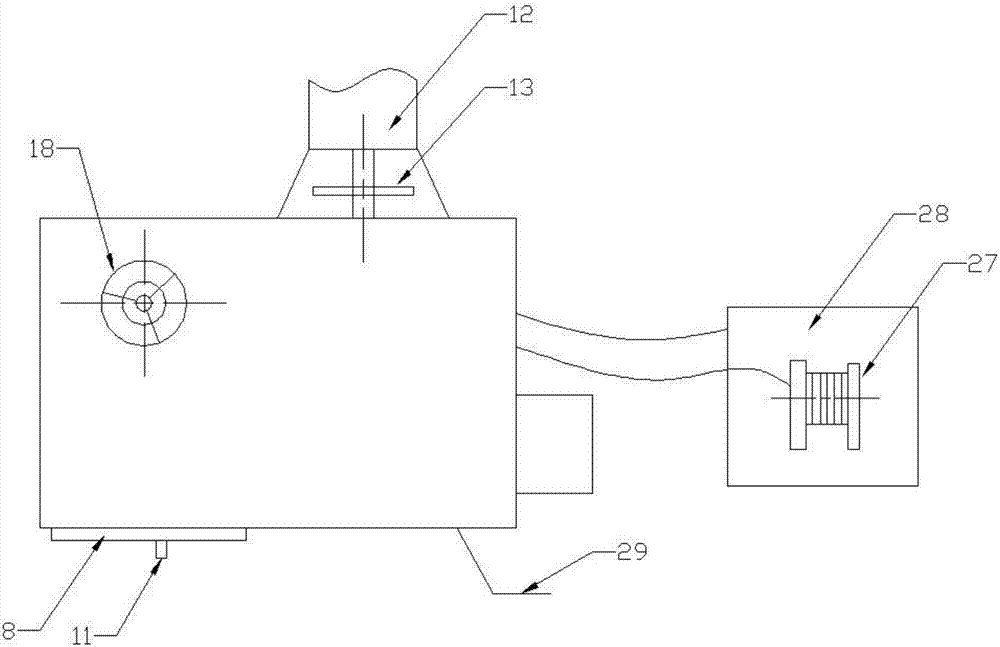

[0018] Such as figure 1 with 2 As shown, the main structure of the closed circular bead automatic electric welding machine involved in this embodiment includes a working room 1, a first insulating plate 2, a second insulating plate 3, a welding clamping device 4, a workpiece tooling plate 5, and a rotating drive Motor 6, motor connecting sleeve 7, movable baffle 8, fixed baffle 9, observation manhole 10, handle 11, smoke outlet 12, exhaust fan 13, welding gun extension length adjustment switch 14, welding gun height adjustment switch 15, welding gun Angle adjustment switch 16, rotary drive motor speed adjustment switch 17, intake pipe 18, U-shaped support frame 19, cylinder 20, telescopic rod 21, welding gun support arm 22, fixed rod 23, welding gun adjustment device 24, welding gun 25, carbon dioxide gas supply pipe 26. Wire feeding device 27, motor 28 and foot control switch 29; the second insulating plate 3 is fixedly arranged in the closed working room 1, the welding clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com