Minitype extrusion spray head for mixed color printing

A miniature, color-mixing technology, applied in the field of 3D printing, can solve the problems of uneven silk material, nozzle spinneret fault, affecting the surface roughness of printed products, etc., to achieve stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

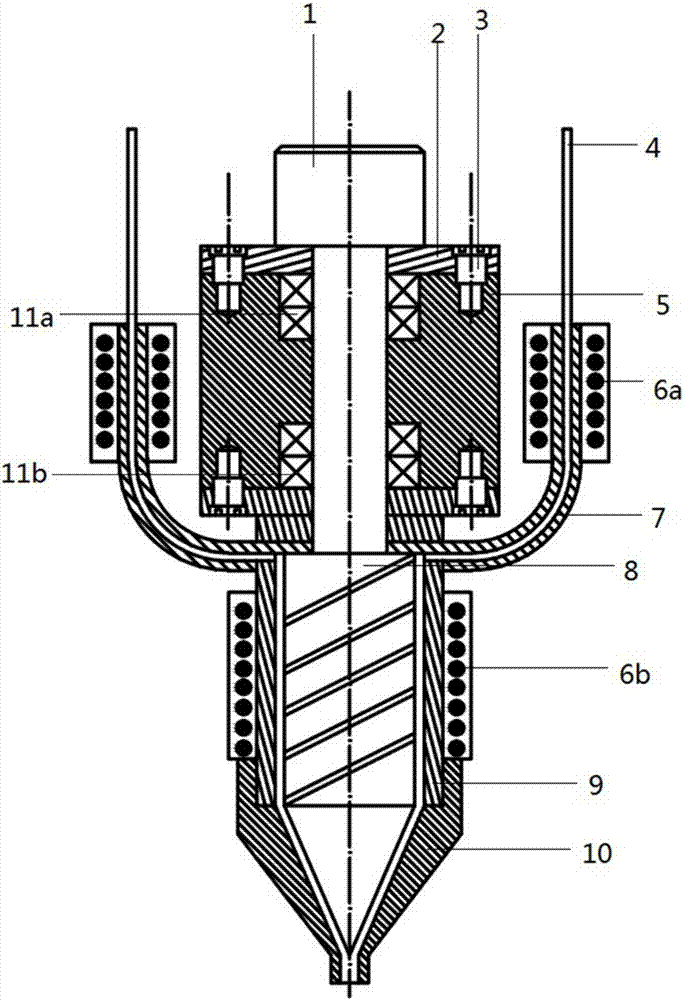

[0025] Such as figure 1 and figure 2 As shown, a micro-extrusion nozzle for color mixing printing with dual filament channels, including a driving motor 1, a motor end cover 2, a round nut 3, a thermoplastic filament 4, a bearing seat 5, a heating device 6a, a preheating device 6b, and a filament Channel 7, screw 8, barrel 9, nozzle 10, bearings 11a, 11b. Wherein the nozzle 10 is a conical nozzle, the nozzle 10 and the barrel 9 are connected by an internal thread, the outside of the barrel 9 is equipped with a heating device 6b, and the heating device 6b is an electromagnetic heater, and a heating device 6b is installed in the barrel 9. The screw 8 for extruding materials, wherein the tail end of the screw 8 is a shaft structure, the shaft at the tail end of the screw 8 is installed on the bearing housing 5 through two front and rear bearings 11a, 11b, and the middle part of the screw 8 is used for extrusion plasticization The thread structure is used for stirring, melting ...

Embodiment 2

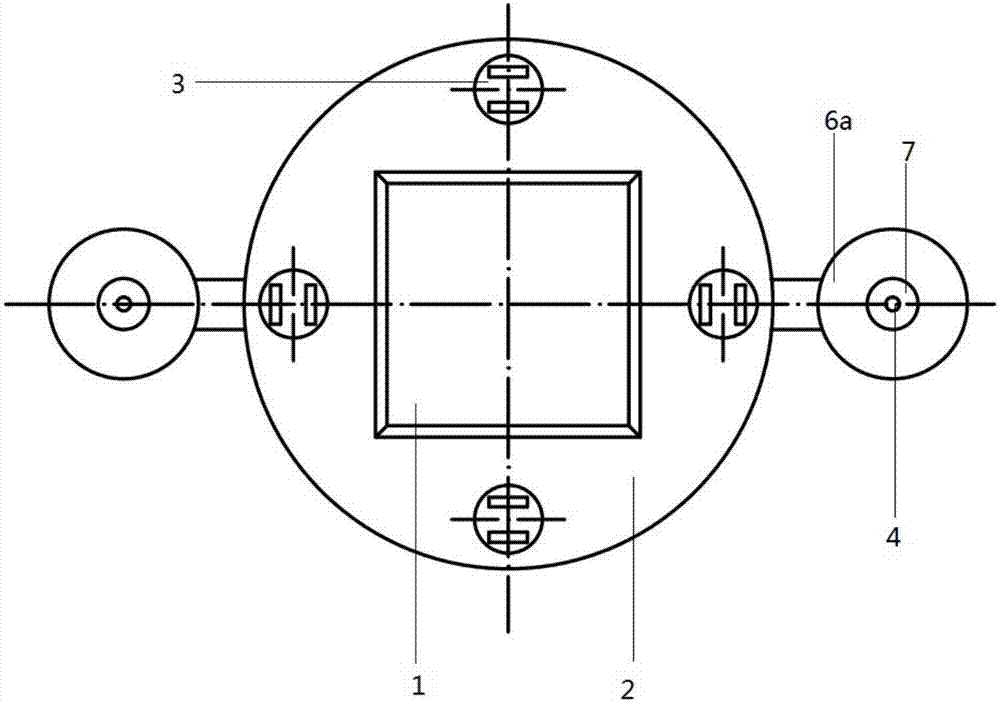

[0031] Embodiment 2 is the same as other structures of Embodiment 1, and the difference is that there are three filament passages 7 in Embodiment 2 (such as image 3 shown) in order to achieve mixed printing of three kinds of thermoplastic materials. Since the general color adopts the RGB three-color principle, it is more common to use three filament channels 7, and each filament channel 7 enters a thermoplastic material of one color, which can realize arbitrary Color matching.

Embodiment 3

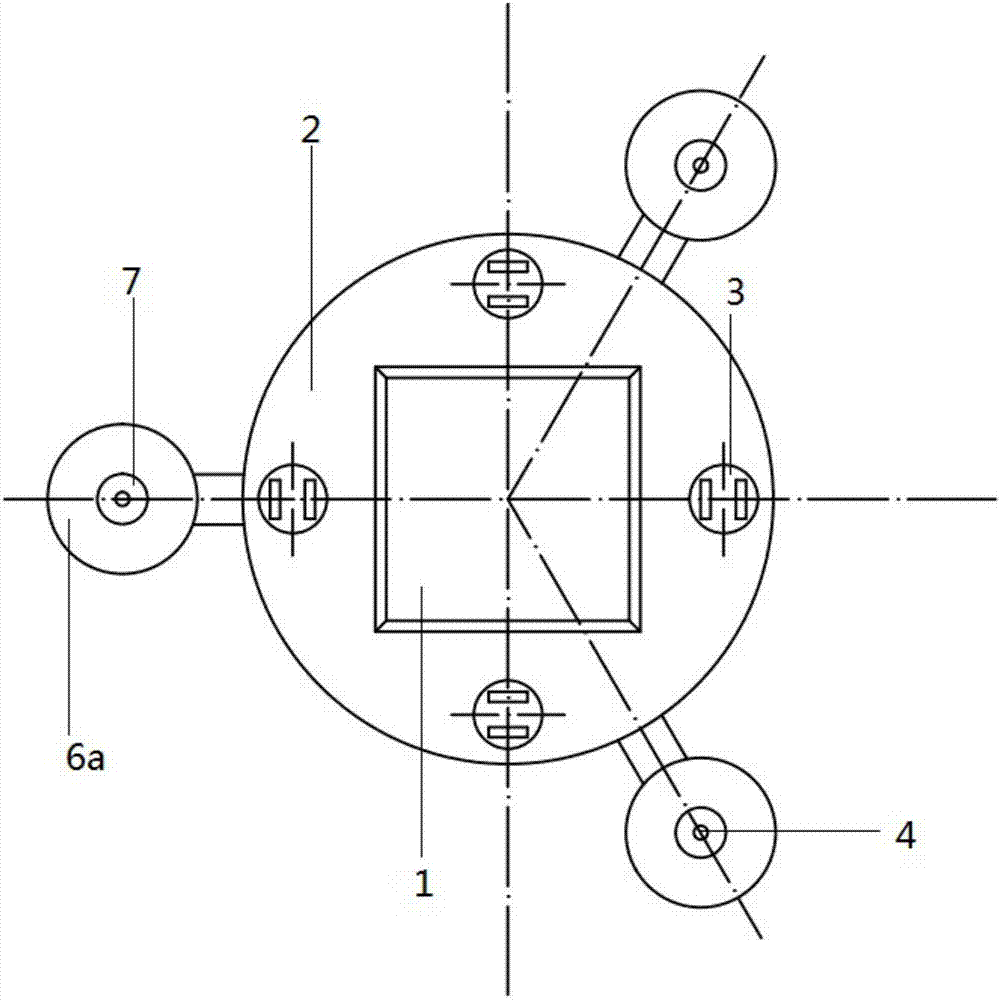

[0033] Embodiment 3 is the same as other structures of Embodiment 1, and the difference is that there are four filament passages 7 in Embodiment 3 (such as Figure 4 shown) in order to realize mixed printing of four kinds of thermoplastic materials, suitable for mixed printing of thermoplastic materials with various properties and colors, one or two of the four filament passages 7 in this embodiment 3 can also be used as spare filament passages 7 , to prevent other wire passages 7 from being blocked.

[0034] In order to solve the feed ratio problem of different colors or types of thermoplastic materials, a circle of wire channels 7 of different sizes can be arranged around the tail end of the barrel. When in use, thermoplastic wires 4 of different diameters are used to pass through the thermoplastic wires Diameter selection to choose feed rate and proportion.

[0035] Compared with the prior art, this patent can feed the thermoplastic filament into the barrel with a smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com