Automatic supporting-plate-free cement brick stacking device and method and packing production line

A cement brick and production line technology, applied in the stacking, unstacking, transportation and packaging of objects, etc., can solve the problems of large pallet occupation, waste of human resources, waste of human and material resources, etc., to improve work efficiency, Realize automatic operation and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

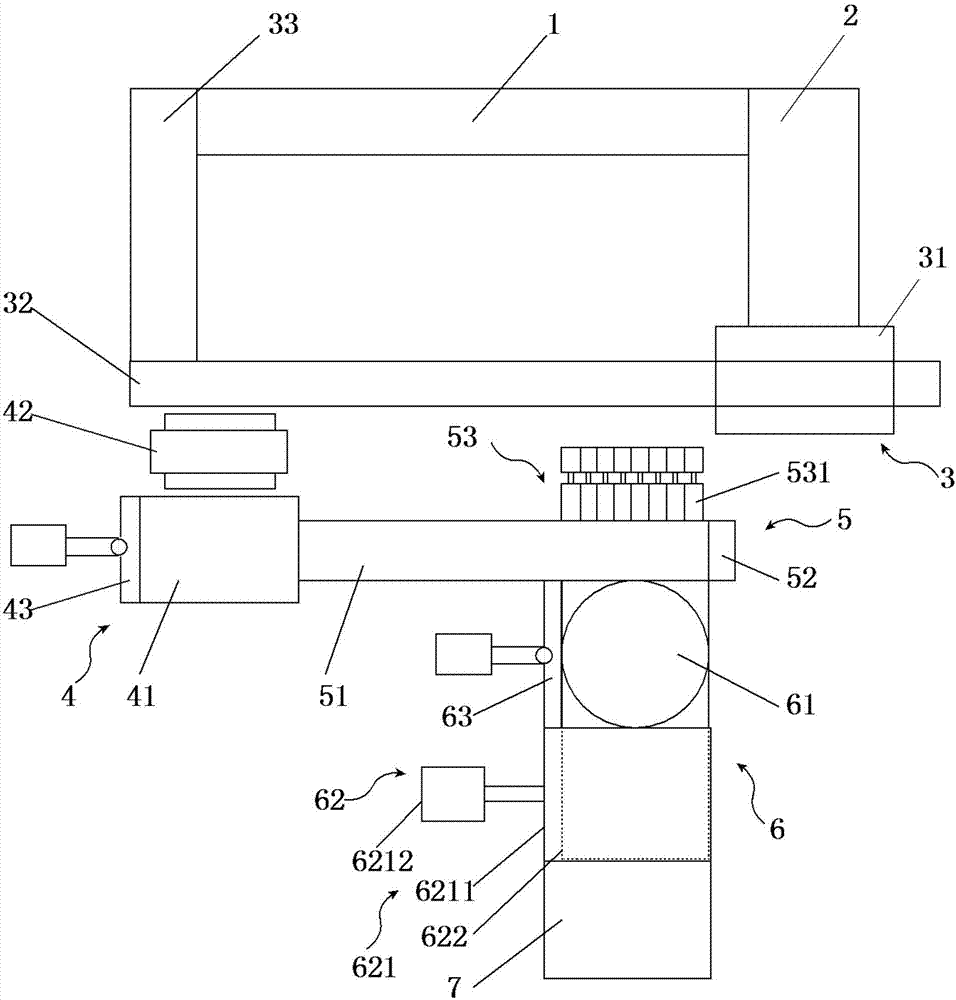

[0036] It includes: conveying brick pushing equipment 5 and empty palletizing equipment 6 arranged in sequence. The conveying brick pushing equipment 5 includes a conveyor 51. One side of the conveyor 51 is empty palletizing equipment 6, and the other side is empty palletizing equipment 6. The corresponding position of the equipment 6 is provided with a brick pusher 53, the brick pusher 53 includes several brick pusher manipulators 531 arranged side by side, and the empty stacking equipment 6 includes a turntable 61 arranged on one side of the conveyor 51, one part of the turntable 61 A palletizing device 62 is provided on the side.

[0037] The cement brick layer of the present invention passes successively through the conveying brick pushing equipment 5 and the empty stacking equipment 6, and under the cooperation of the turntable 61 and the brick pushing manipulator 531, the cement bricks are further arranged and combined according to the requirements, and the stacking devic...

Embodiment 2

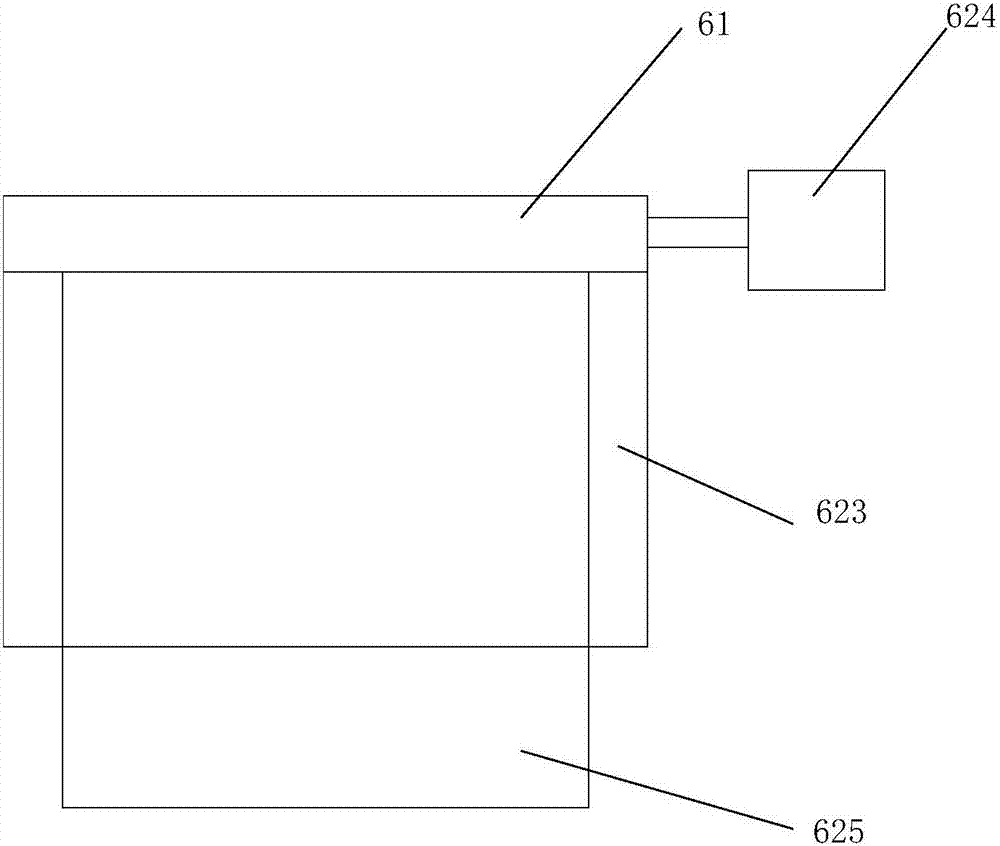

[0045] The palletizing device 62 includes a lifting device 623 connected to the turntable 61, and a power unit 624 that moves the turntable 61 horizontally. The power unit 624 is a rodless cylinder, and a palletizer 625 is arranged below the turntable 61. Others are the same as in the first embodiment.

[0046] After the turntable 61 of the present invention adjusts the position of each layer of cement bricks, the lifting device is used to move down to the stacker, and the turntable 61 is horizontally drawn away by the power device, and the cement bricks fall to the pallet below under the action of inertia on board.

[0047] A pallet-free automatic palletizing method for cement bricks, comprising the following steps:

[0048] 1) Stack cement bricks less than N layers in turn, and N is an integer greater than or equal to 1;

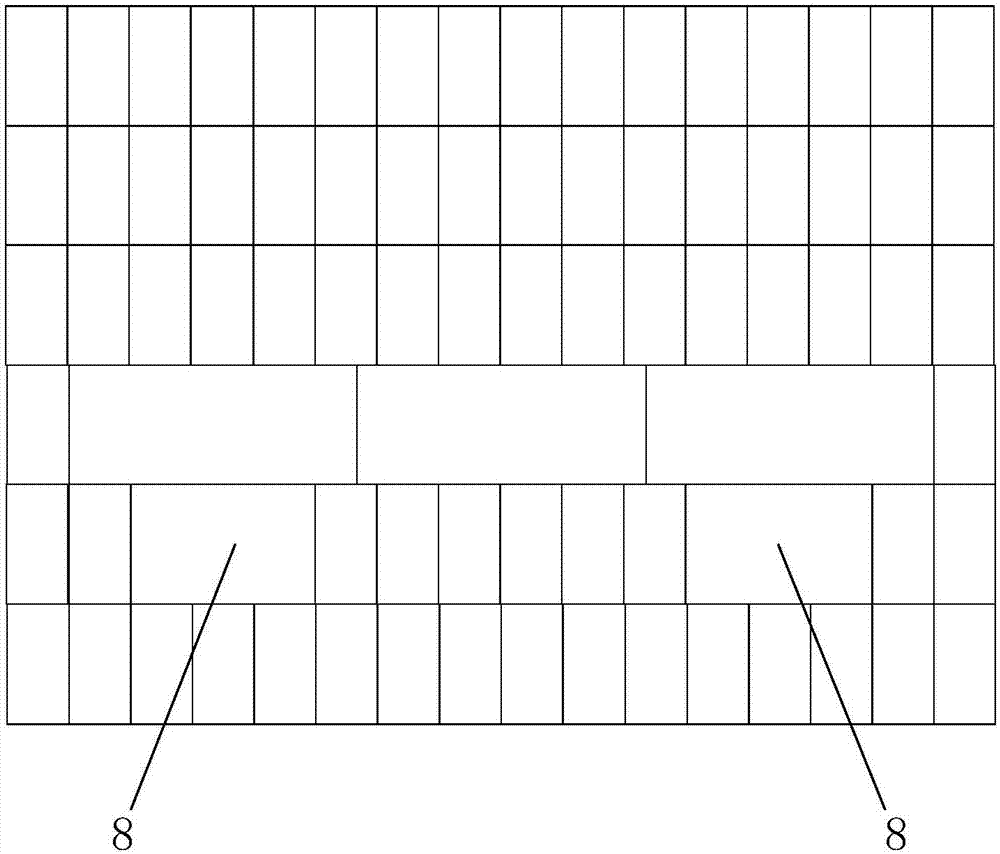

[0049] 2) There is an empty structure 8 in the Nth layer of cement bricks, and several columns of cement bricks other than the empty structure 8 in the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com