Sponge city low-lying land multistage cascading rotary purification system

A sponge city and purification system technology, applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of rainwater purification collection and utilization, limited runoff reduction, and impact on the regional environment, so as to reduce the cost of artificial irrigation and reduce Eutrophication and good landscape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

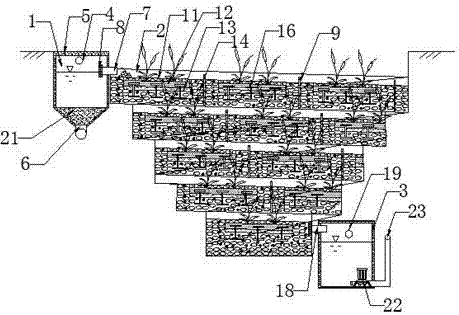

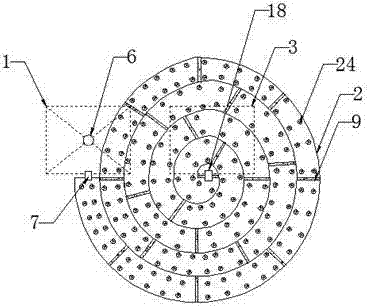

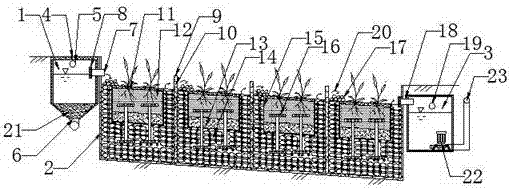

[0023] see Figure 1-Figure 4 , the present invention is a multi-level stacked water rotary purification system for low-lying areas in sponge cities, including a sediment collection tank 1, a rotary purification channel 2 and a reservoir 3, the sediment collection tank 1 is set on the top of the low-lying land, and the sand collection tank 1 The top is provided with an inspection cover 2, the upper part is provided with the inlet hole 5 of the sand settling pool, the middle part is provided with the outlet hole 7 of the sand settling pool, the outlet hole 7 of the sand setter pool is provided with a trash rack 8, and the lower part is a funnel-shaped The sand outlet 6, the sand outlet 6 is connected with the sand outlet pipe; the rotary purification channel 2 is arranged in a spiral downward along the surrounding of the low-lying land, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com