A magnesium oxysulfate cement foam concrete sand stabilizing plate and a preparing method thereof

A technology of magnesium oxysulfate cement and foam concrete, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of short service life, secondary pollution and high cost of sand control and sand fixation materials, and achieve excellent performance advantages, production and installation. Convenient and fast, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

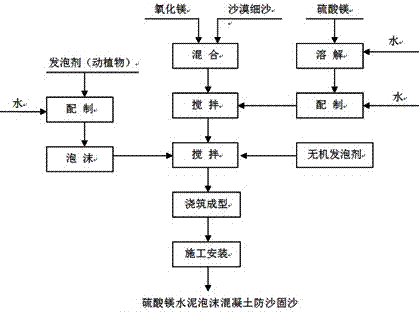

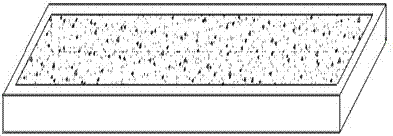

[0029] A magnesium oxysulfide cement-based material is characterized in that it consists of the following components: magnesium sulfate, magnesium oxide, fine sand, water and foam made from plant foaming agents.

[0030] For the magnesium oxysulfide cement-based material, the weight ratio of magnesium oxide and fine sand is 1:8, the concentration of magnesium sulfate solution is 22Be', and the weight ratio of mixture (magnesium oxide, fine sand) and magnesium sulfate solution is 1:4 , the foam that animal and plant foaming agent makes and magnesium oxysulfide cement concrete slurry are 0.08: 1 by weight. A kind of preparation method of magnesium oxysulfide cement foam concrete sand-fixing board comprises the following steps:

[0031] S1, magnesium sulfate (MgSO 4 ) and water (H 2 O) Prepare a magnesium sulfate solution with a concentration of 22 Be'; fully mix magnesium oxide and fine sand in a weight ratio of 1:8.

[0032] S2. Mixing the magnesium sulfate solution obtained ...

Embodiment 2

[0037] A magnesium oxysulfide cement-based material is characterized in that it consists of the following components: magnesium sulfate, magnesium oxide, fine sand, water and foam made from plant foaming agents.

[0038] For the magnesium oxysulfate cement-based material, the weight ratio of magnesium oxide and fine sand is 1:1, the concentration of magnesium sulfate solution is 15Be', and the weight ratio of mixture (magnesium oxide, fine sand) and magnesium sulfate solution is 1:1 , the foam that animal and plant foaming agent makes and magnesium oxysulfide cement concrete slurry are 0.01:1 by weight. A kind of preparation method of magnesium oxysulfide cement foam concrete sand-fixing board comprises the following steps:

[0039] S1, magnesium sulfate (MgSO 4 ) and water (H 2 O) Prepare a magnesium sulfate solution with a concentration of 15 Be’; fully mix magnesium oxide and fine sand in a weight ratio of 1:1.

[0040] S2. Mix the magnesium sulfate solution obtained in s...

Embodiment 3

[0045] A magnesium oxysulfide cement-based material is characterized in that it consists of the following components: magnesium sulfate, magnesium oxide, fine sand, water and foam made from plant foaming agents.

[0046] For the magnesium oxysulfide cement-based material, the weight ratio of magnesium oxide and fine sand is 1:30, the concentration of magnesium sulfate solution is 32Be', and the weight ratio of mixture (magnesium oxide, fine sand) and magnesium sulfate solution is 1:20 , the foam made of animal and plant foaming agents and magnesium oxysulfide cement concrete slurry are in a weight ratio of 0.3:1.

[0047] A kind of manufacture method of magnesium oxysulfate cement foam concrete sand-fixing board, comprises the following steps:

[0048] S1, magnesium sulfate (MgSO 4 ) and water (H 2 O) Prepare a magnesium sulfate solution with a concentration of 32 Be'; fully mix magnesium oxide and fine sand at a weight ratio of 1:30.

[0049] S2. Mixing the magnesium sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com