Method for rectification dehydration of 2-methylpyridine

A methylpyridine and rectification technology, applied in fractionation, distillation regulation/control, organic chemistry, etc., can solve problems such as resource waste, environmental pollution, and inability to separate mixtures, and achieve simple equipment, good separation effect, and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

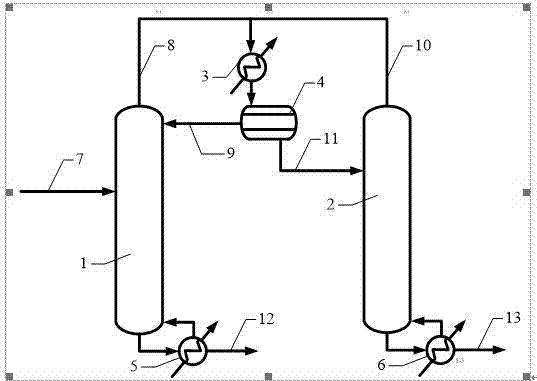

[0022] The azeotropic rectification tower is a tray tower with a diameter of 1200mm and a height of 5 meters. There are 8 trays inside. The mixture of raw materials 2-picoline and water enters the tower from the second tray at a flow rate of 10000 kg / h. The mass fraction of 2-picoline in the raw material mixture is 90%, and the water is 10%. The operating pressure of the azeotropic distillation tower is 1 atm. In the azeotropic distillation tower, since 2-picoline and water form the lowest azeotrope, the steam close to the azeotropic composition will be drawn from the top of the tower, and the temperature at the top of the tower is 95- 96 ° C, cooled to 40-45 ° C by the top condenser 3, then enters the stratifier 4, and is divided into two liquid phases at 4, one is an organic phase (containing a large amount of organic phase return pipe and a small amount of water), and the other is water Phase (containing a large amount of water and a small amount of 2-picoline). The organi...

Embodiment 2

[0025] The azeotropic rectification tower is a tray tower with a diameter of 1200mm and a height of 6 meters. There are 10 trays inside. The mixture of raw materials 2-picoline and water enters the tower from the third tray at a flow rate of 10000 kg / h. The mass fraction of 2-picoline in the raw material mixture is 95%, and the water is 5%. The operating pressure of the azeotropic distillation column 1 is 0.8 atm. In the azeotropic distillation column 1, since 2-picoline and water form the lowest azeotrope, the steam close to the azeotropic composition will be drawn from the top of the column, and the temperature at the top of the column will be It is 88-89°C, cooled to 40-45°C by the top condenser 3, and then enters the stratifier 4, where it is divided into two liquid phases, one is an organic phase (containing a large amount of organic phase reflux pipe and a small amount of water), The other is the aqueous phase (containing a large amount of water and a small amount of 2-p...

Embodiment 3

[0028] The azeotropic rectification tower is a plate tower with a diameter of 1000mm and a height of 5 meters. There are 16 trays inside. The mixture of raw materials 2-picoline and water enters the tower from the fifth plate at a flow rate of 10000 kg / h. The mass fraction of 2-picoline in the raw material mixture is 93%, and the water is 7%. The operating pressure of the azeotropic distillation tower is 1 atm. In the azeotropic distillation tower, since 2-picoline and water form the lowest azeotrope, the steam close to the azeotropic composition will be drawn from the top of the tower, and the temperature at the top of the tower is 95- 96 ° C, cooled to 40-45 ° C by the top condenser 3 and then enters the stratifier 4, where it is divided into two liquid phases, one is the organic phase (containing a large amount of organic phase return pipe and a small amount of water), and the other is Aqueous phase (contains a large amount of water and a small amount of 2-picoline). The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com