Low-odor and low-friction-coefficient injection-molding skin material and preparation method thereof

A low friction coefficient, skin material technology, applied in the field of thermoplastic elastomer material production and its blending modification, can solve the problems of affecting the service life of human health, the smell of the skin material, and the high cost of human and material resources, and achieve a delicate hand feel. Smooth, low friction coefficient, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment provides a kind of low smell, low coefficient of friction injection molded skin material, comprise the high fluidity polypropylene of 25 parts by weight, the graft EPDM of 20 parts by weight, the POE of 15 parts by weight, the paraffin oil of 35 parts by weight, 1.5 parts by weight Parts (relative to rubber) of peroxide, 3 parts by weight of self-lubricating agent, and 2 parts by weight of anti-wear agent.

[0022] Wherein, the grafted EPDM is silane-grafted EPDM made by the company, the POE is conventional POE, and the polypropylene is high-fluidity polypropylene with a fluidity ≥ 85 (230°C*2.16KG). The paraffin oil described above is preferably environment-friendly paraffin oil, the peroxide is one or more of powder DCP, liquid initiator, BPIC, TBIC, and the anti-wear agent is two-stage grafting reaction type anti-wear agent, and the self-lubricating agent is one or more of modified polyethylene wax, erucamide, and oleamide.

[0023] This embod...

Embodiment 2

[0029] The main difference between this embodiment and Example 1 is that the high fluidity polypropylene of 20 parts by weight of the formula, the grafted EPDM of 20 parts by weight, the POE of 20 parts by weight, the paraffin oil of 35 parts by weight, 1.5 parts of ( Relative rubber) peroxide, 3 parts by weight of self-lubricating agent, 2 parts by weight of wear-resistant agent.

Embodiment 3

[0031] The main difference between this embodiment and Example 1 is that the high-fluidity polypropylene of 30 parts by weight of the formula, the grafted EPDM of 15 parts by weight, the POE of 15 parts by weight, the paraffin oil of 35 parts by weight, 1.5 parts of ( Relative rubber) peroxide, 3 parts by weight of self-lubricating agent, 2 parts by weight of wear-resistant agent.

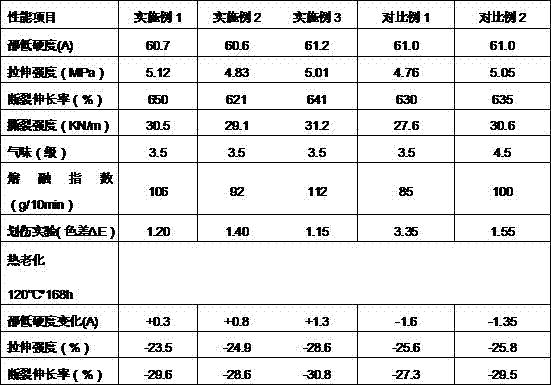

[0032] A group of comparative test examples are listed below to illustrate the beneficial effects of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com