Prepreg compound and method for preparing honeycomb core through prepreg compound

A technology of prepreg and honeycomb core, which is applied in the field of honeycomb core, can solve serious problems such as uneven glue coating and less glue at the glue strip, and achieve the effects of easy large-scale production, simple preparation method, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of prepreg

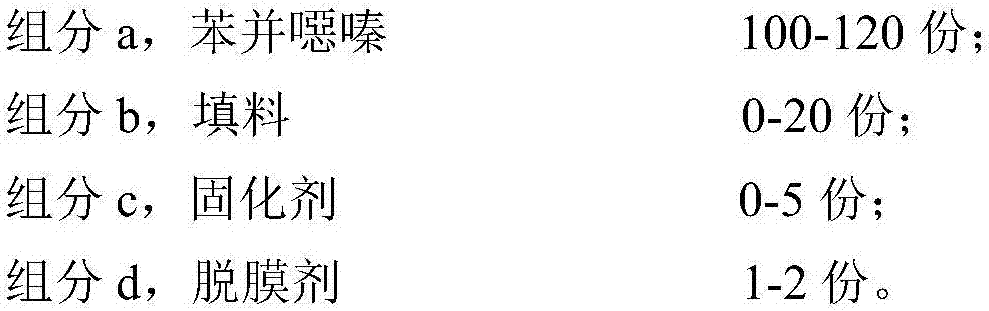

[0054] Add 1 part of release agent to 100 parts of phenol-diaminodiphenylmethane type benzoxazine at 120° C., mix well to prepare a benzoxazine resin system mixture.

[0055] At 120°C, using a melting normal thickness of 0.1mm and a density of 100m 2 Impregnate the benzoxazine resin system mixture on the glass cloth of warp yarn 16 and weft yarn 15 to obtain the prepreg, control the content of the benzoxazine resin system in the prepreg after dipping to be 42wt% .

[0056] (2) Preparation of honeycomb core

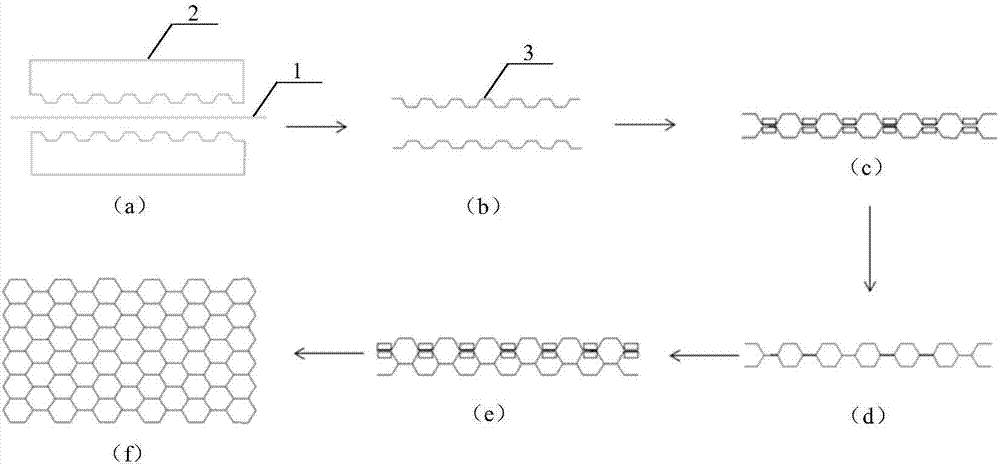

[0057] like figure 1 Shown is a schematic flow chart of the preparation method of the honeycomb core. The preparation method of described honeycomb core comprises the steps:

[0058] I, the prepreg 1 (multi-layer) is laid between two protruding molds 2, such as figure 1 As shown in (a), apply a pressure of 0.5 MPa to the mold, mold it at 120°C for 1 hour, and get out of the semi-regular hexagonal corrugated structure honeycomb pane...

Embodiment 2

[0063] The preparation of the prepreg and the preparation of the honeycomb core were the same as in Example 1, except that the size of the mold was adjusted to prepare a honeycomb core with a honeycomb aperture of 9.6 mm. The test results of density and mechanical properties are shown in Table 1.

Embodiment 3

[0065] (1) Preparation of prepreg

[0066] Add 1 part of release agent and 10 parts of aluminum hydroxide to 100 parts of bisphenol A-aniline benzoxazine at 120° C., mix well to prepare a benzoxazine resin system mixture.

[0067] At 120°C, using a melting normal thickness of 0.1mm and a density of 100m 2 Impregnate the benzoxazine resin system mixture on the glass cloth of warp yarn 16 and weft yarn 15 to obtain the prepreg, control the content of the benzoxazine resin system in the prepreg after dipping to be 45wt% .

[0068] (2) Preparation of honeycomb core

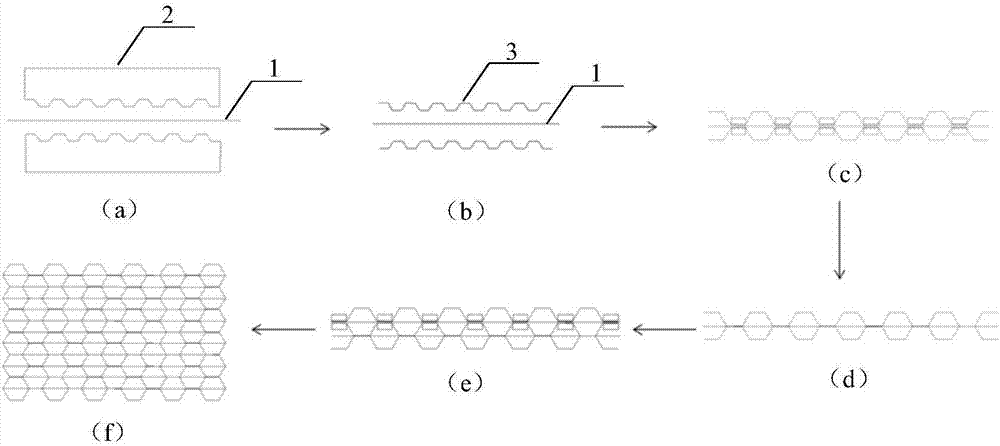

[0069] like figure 2 Shown is a schematic flow chart of the preparation method of the honeycomb core. The preparation method of described honeycomb core comprises the steps:

[0070] I, the prepreg 1 (multi-layer) is laid between two protruding molds 2, such as figure 2 As shown in (a), apply a pressure of 0.5 MPa to the mold, mold it at 120°C for 1 hour, and get out of the semi-regular hexagonal corrugated st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com