Efficient inorganic vacuum heat-insulation plate

A vacuum insulation panel, inorganic technology, applied in the direction of insulation improvement, climate change adaptation, building components, etc., can solve the problems of reduced vacuum degree, need to improve thermal insulation effect, large thermal conductivity, etc., to reduce the rate of gas leakage , Good thermal insulation effect, reliable thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

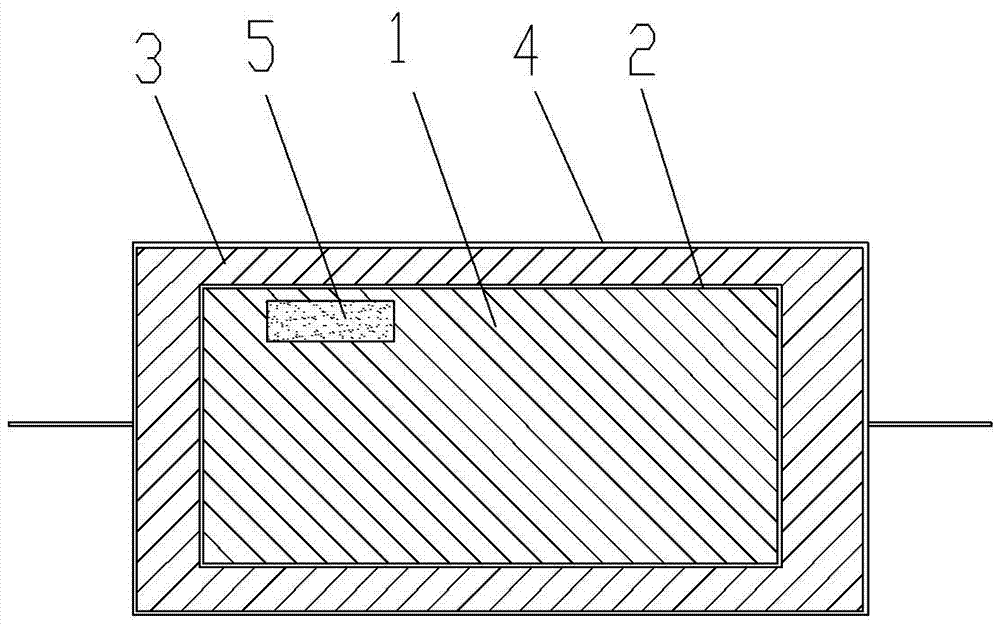

[0015] Such as figure 1 As shown, a high-efficiency inorganic vacuum insulation panel provided by the present invention includes a core panel 1, an inner barrier bag 2 is sealed and wrapped outside the core panel 1, an outer barrier bag 4 is sealed and wrapped outside the inner barrier bag 2, and an outer barrier bag 4 is sealed and wrapped outside the outer barrier bag 2. The outside of the bag 4 is also coated with PVDC, PVA, SiO X or Al 2 o 3 . A getter 5 is arranged between the core board 1 and the barrier bag 2, and a transitional vacuum layer 3 is filled between the inner barrier bag 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap