Chimney for eliminating wet method desulfurization white smoke

A wet desulfurization and chimney technology, applied in the field of flue gas whitening chimneys, can solve the problems of large project investment and sharp increase of total flue gas volume, and achieve the effect of small renovation works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

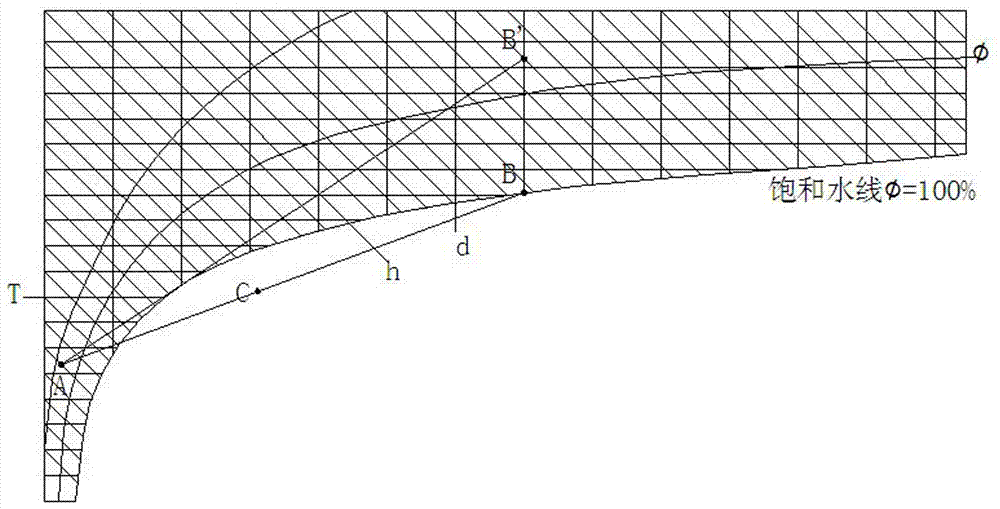

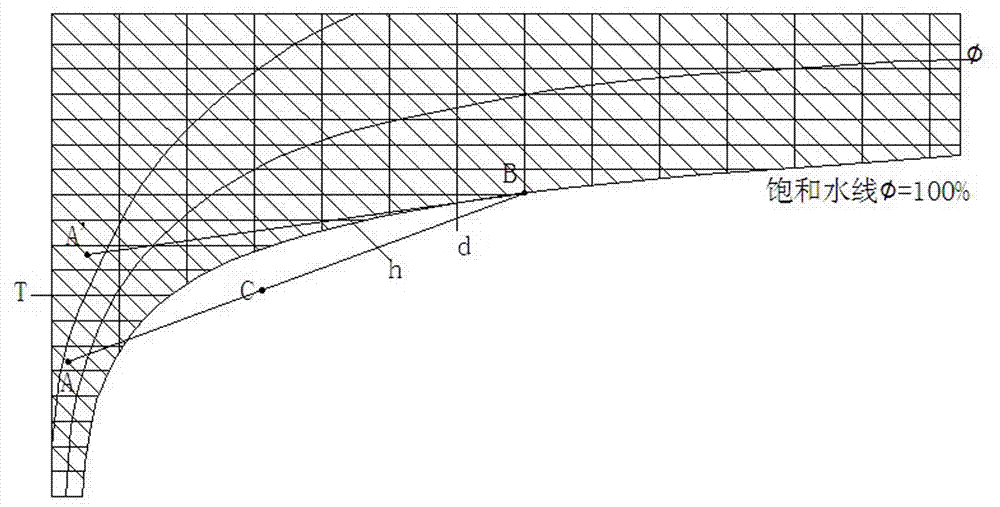

Method used

Image

Examples

Embodiment 1

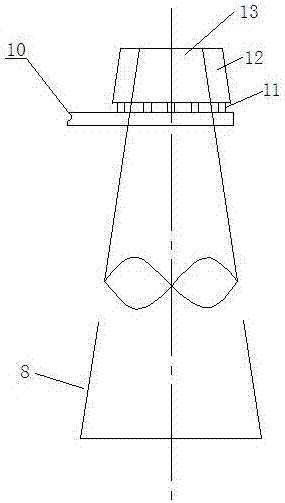

[0033] Such as image 3 and Figure 4 As shown, a chimney for eliminating wet desulfurization white smoke is provided with a chimney jacket 12 on the top of the chimney body 8, and the annular interlayer of the chimney jacket 12 is a hot air outlet channel, and the top of the annular interlayer is open for hot air. The air outlet is closed at the bottom and communicates with the hot air main pipe 10 through the hot air branch pipe 11 , and the hot air branch pipe 11 is evenly arranged around the chimney body 8 .

[0034] In the wet desulfurization process, the flue gas generated by the combustion of the boiler or other heating device 1 passes through the denitrification tower 2 to remove nitrogen oxides, then passes through the air preheater 3 for cooling and cooling, and then removes dust in the electrostatic precipitator 4, cooling and dust removal The final flue gas is desulfurized in the wet desulfurization tower 5, and the temperature of the wet flue gas after desulfuriz...

Embodiment 2

[0036] Such as Figure 5 and Figure 6 As shown, a chimney for eliminating white smoke from wet desulfurization, hot air branch pipes 11 are evenly arranged around the top of the chimney as hot air outlet channels, the bottom of the hot air branch pipes 11 communicates with the hot air main pipe 10, and the hot air passes through the hot air The branch pipe 11 is directly discharged into the atmosphere, and is contacted and mixed with the wet flue gas discharged from the chimney body, and wrapped on the surface of the wet flue gas to achieve the purpose of eliminating white smoke and chimney rain.

[0037] The hot air entering the hot air main pipeline 10 in this embodiment can be produced by other processes different from those in Embodiment 1, such as cold air and high-temperature flue gas heat exchange before desulfurization, and the cold air is directly generated by electric heating , or hot air generated by other methods such as cold air and steam heat exchange;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com