Wafer box transmission device

A technology for conveying devices and wafer boxes, which is applied in the direction of conveyor objects, transportation and packaging, semiconductor devices, etc., can solve the problems of increased use cost, large power consumption, and high cost, and achieve cost reduction, efficiency improvement, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations. The invention described herein is not limited to handling wafer cassettes, for example, various embodiments of the present invention may also be applied and / or adapted to handle standard mechanical interface cassettes, raster cassettes, flat panel displays, or any other container or processing equipment . The container is defined as any type of structure for carrying items including, but not limited to, wafers. For the purpose of describing the invention, reference will be made only to cassettes for transporting wafers.

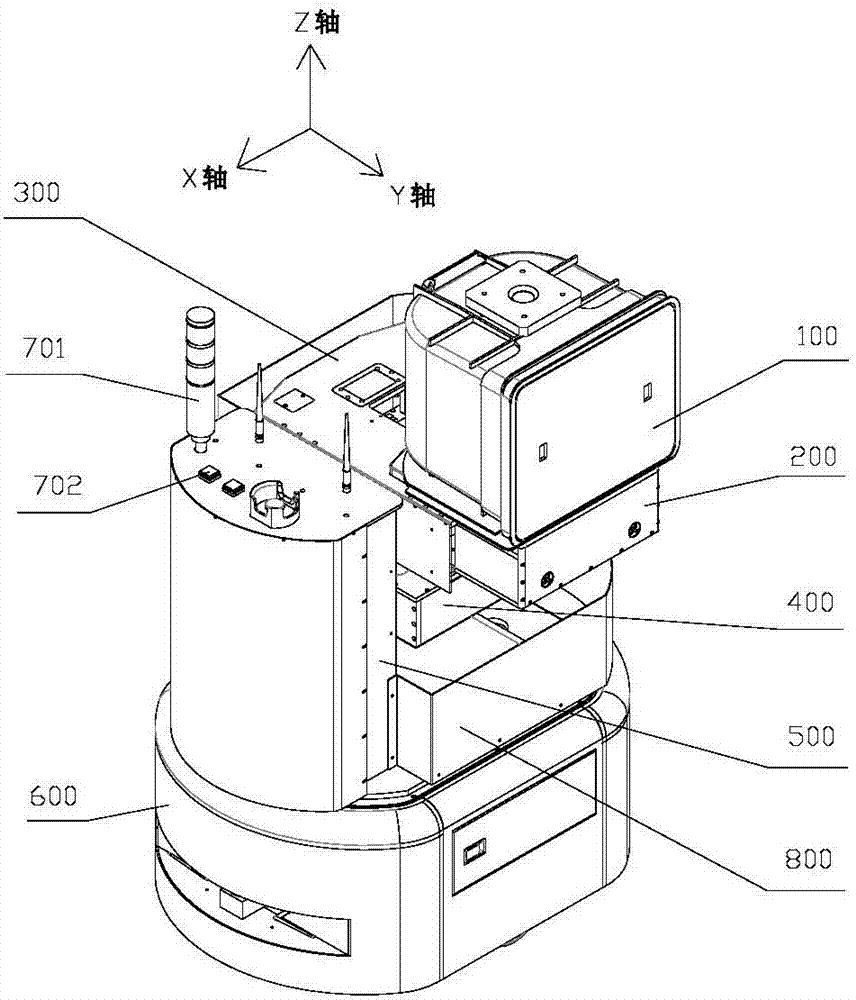

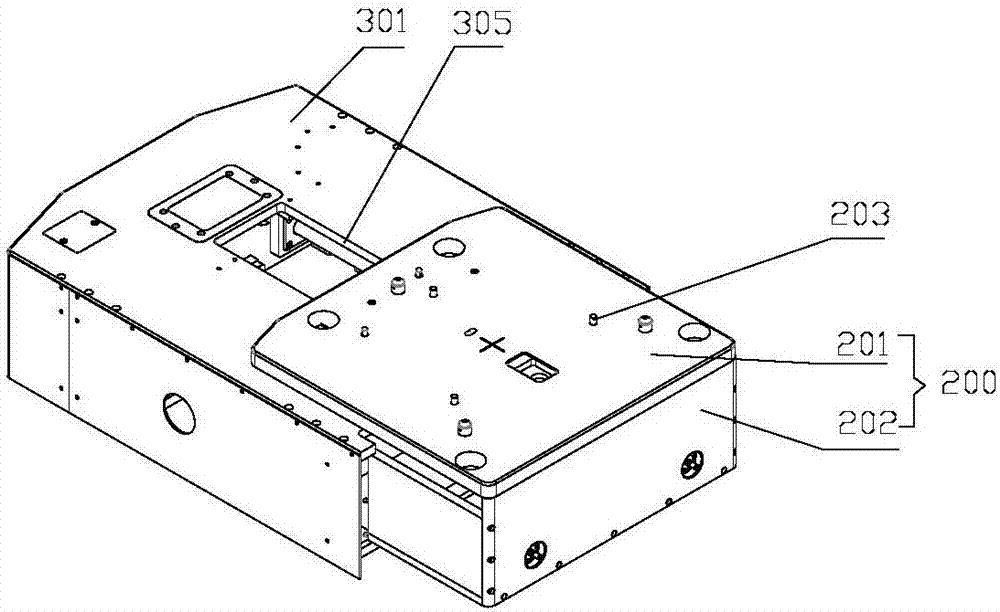

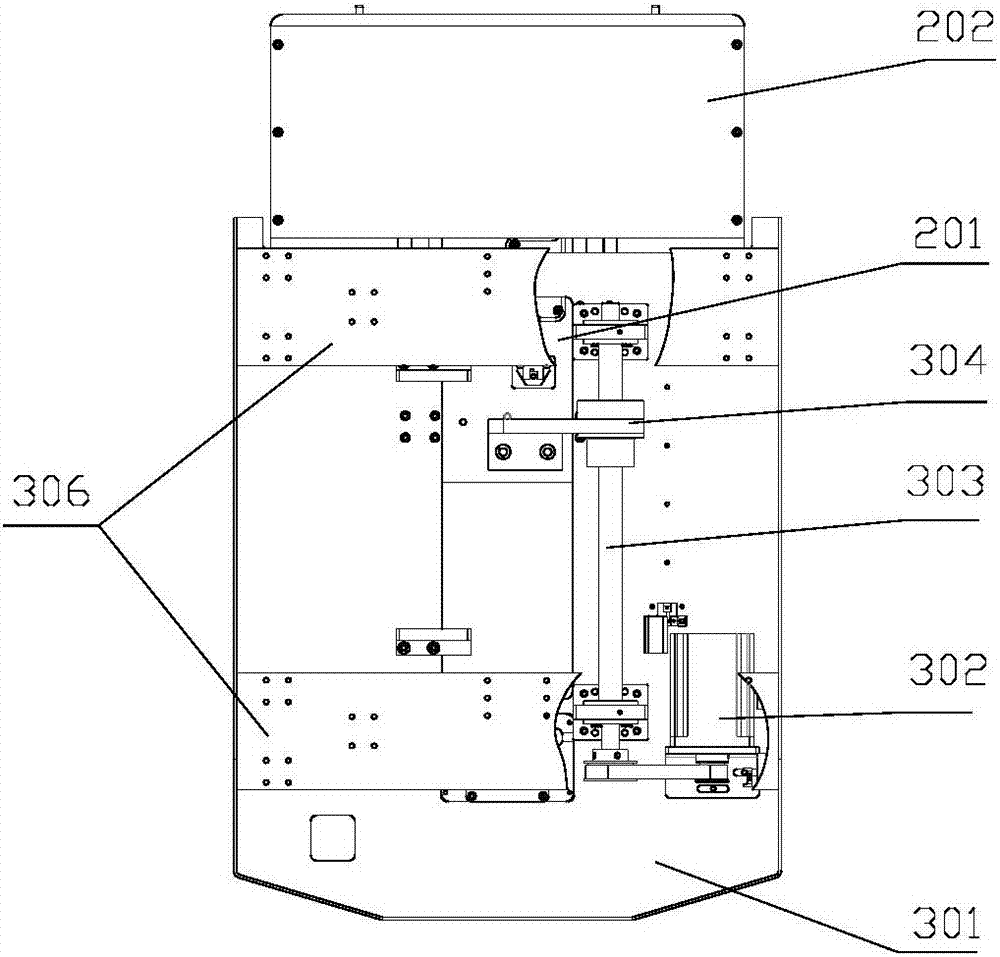

[0046] refer to figure 1, shows a wafer cassette conveying device according to a preferred embodiment of the present invention, including a carrying mechanism 200, a translation mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com