Microelectronic package lead frame in matrix form

A technology for encapsulating leads and microelectronics, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of poor lead frame precision, low density, lack of refinement of external pins, etc., to improve the processing level and promote renewal. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained in detail below in conjunction with the examples, and the examples are only for explanation and are not intended to limit the present invention.

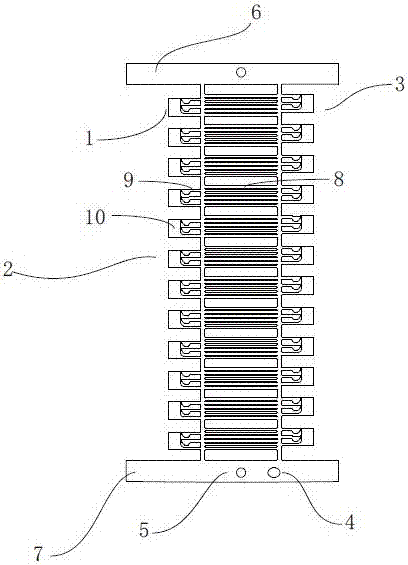

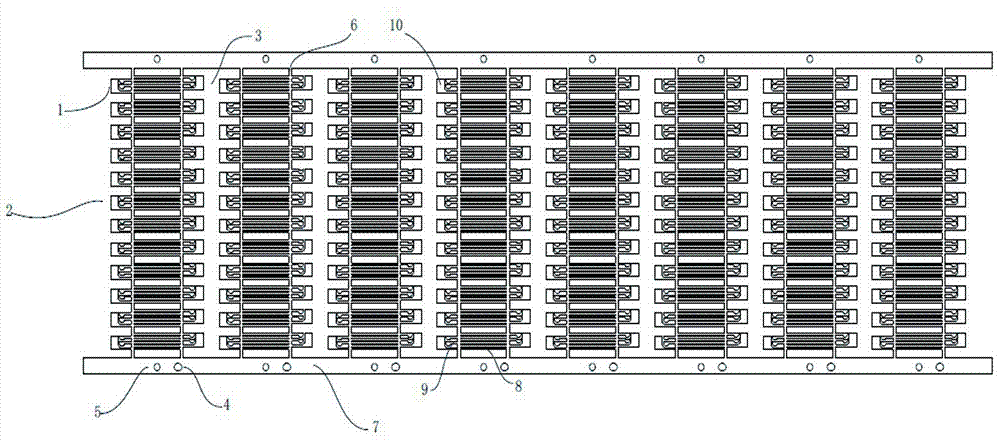

[0023] like figure 2 As shown, a matrix-arranged microelectronic package lead frame according to an embodiment of the present invention, the lead frame as a whole includes a package window unit (1), a package array unit (2), a cross-symmetrical unit (3), and process calibration holes (4 ), mechanical transmission positioning holes (5), connecting middle ribs (6), and lateral positioning guiding main ribs (7); the package array unit (2) is composed of a basic package window unit (1), and the cross-symmetrical unit (3) It is composed of the package array unit (2) rotated and connected, the connecting rib (6) plays a role in connecting and fixing the package window unit (1), package array unit (2) and cross-symmetrical unit (3), and the lateral positioning guide The main reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com