Making technology of half-dried quick-frozen chilled noodles

A production process and cold fresh noodle technology, which is applied in the field of semi-dry quick-frozen fresh noodle production process, can solve problems such as difficult shelf life of products, and achieve the effects of low device cost, improved ripening, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

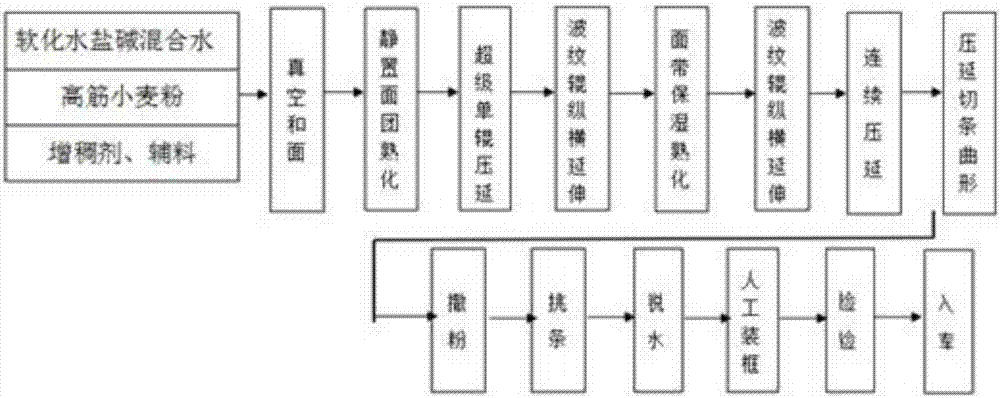

[0029] like figure 1 Shown, a kind of semi-dry quick-frozen fresh noodle making process comprises the steps:

[0030] (1) Vacuum kneading is carried out in a vacuum kneading machine, wherein the kneading time is 900 seconds, the vacuum kneading machine pressure is 70-80kpa, and the water level in the vacuum pump water tank is 40cm;

[0031] (2) Place the dough out of the vacuum dough mixer in a sterile room and let it stand for 30 minutes to ripen;

[0032] (3) Roll the matured dough into a dough cake with a super single roller;

[0033] (4) Extend the dough cake vertically and horizontally with a corrugated roller to obtain a dough strip;

[0034] (5) Place the obtained noodle strips in an environment with a relative humidity of 75-95% and a temperature of 18-25° C. for another 30 minutes;

[0035] (6) Further vertically and horizontally extend the matured noodle strips with corrugated rollers;

[0036] (7) Repeat steps (3)-(6) one to two times;

[0037] (8) the noodle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com