Preparation method of metal phase molybdenum disulfide/two-dimensional carbon nitride photocatalytic material

A photocatalytic material, molybdenum disulfide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limited earth reserves, expensive platinum, etc., and achieve low cost and preparation Simple method, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

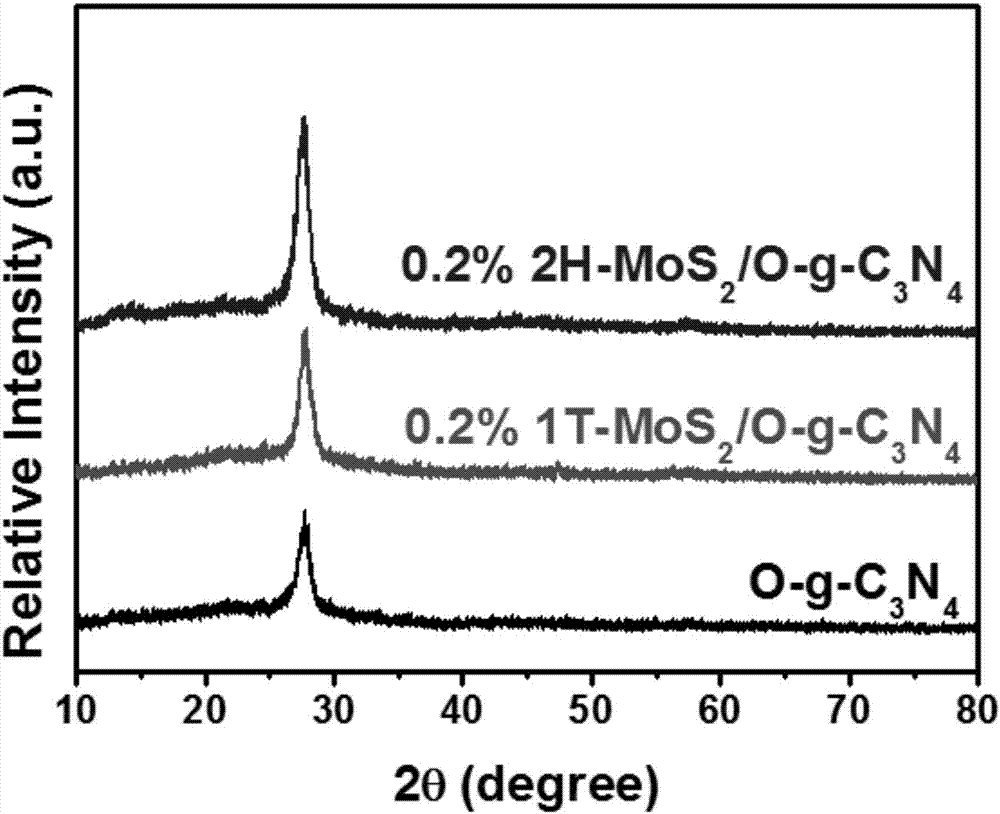

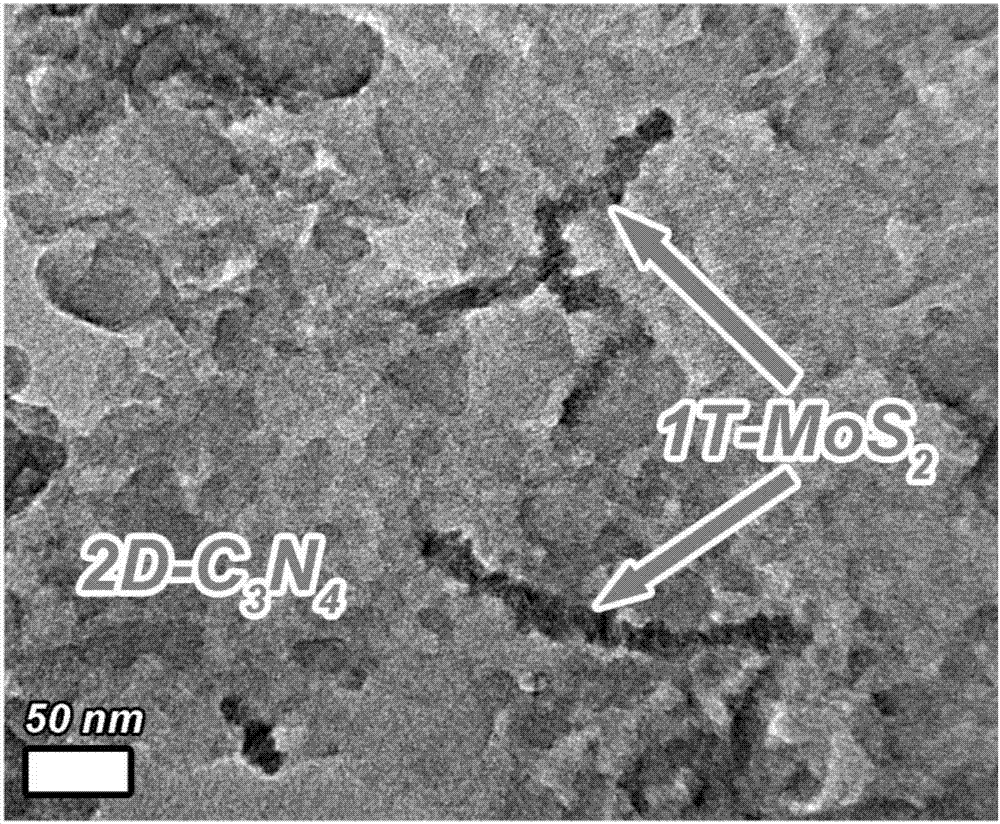

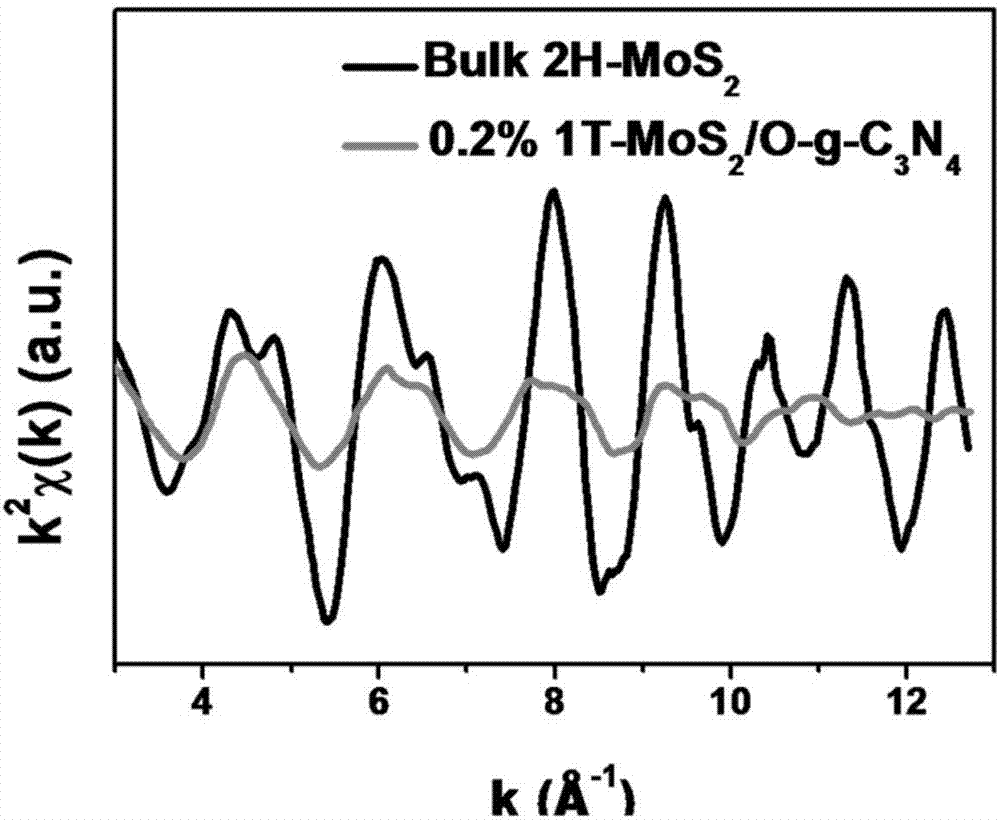

[0025] Embodiment 1: The preparation of metallic phase (1T) molybdenum disulfide / two-dimensional thin layer carbon nitride visible light composite photocatalyst comprises the following steps:

[0026] (1) Put melamine in a ceramic crucible with a cover, heat up to 550°C in a muffle furnace at a rate of 2°C / min and calcinate for 4h to obtain a yellow substance that is ground into powder, and then spread 500mg of the yellow powder on the ark In a muffle furnace, the temperature was raised to 550° C. for 1 h at a rate of 5° C. / min, and then the temperature was raised to 550° C. for 1 h at a rate of 2° C. / min to obtain two-dimensional carbon nitride.

[0027] (2) Add 30ml of dimethylformamide into the beaker, then add 100mg of carbon nitride, 0.0003g of molybdenum pentachloride, and 2.25g of thioacetamide into the beaker, stir for 30min, and disperse by ultrasonication for 30min.

[0028] (3) Transfer the mixed solution to a high-pressure reactor, and place the reactor in an oven ...

Embodiment 2

[0029] Embodiment 2: the preparation of metallic phase (1T) molybdenum disulfide / two-dimensional carbon nitride visible light composite photocatalyst comprises the following steps:

[0030] (1) Put melamine in a ceramic crucible with a cover, heat up to 550°C for 4 hours in a muffle furnace at a rate of 2°C / min and calcinate to obtain a yellow substance that is ground into powder, and then spread 400 mg of the yellow powder in the ark In a muffle furnace, the temperature was raised to 550° C. for 1 h at a rate of 5° C. / min, and then the temperature was raised to 550° C. for 1 h at a rate of 2° C. / min to obtain two-dimensional carbon nitride.

[0031] (2) Add 30ml of dimethylformamide into the beaker, then add 100mg of carbon nitride, 0.0007g of molybdenum pentachloride, and 2.25g of thioacetamide into the beaker, stir for 30min, and disperse by ultrasonication for 30min.

[0032] (3) Transfer the mixed solution to a high-pressure reactor, and place the reactor in an oven at 20...

Embodiment 3

[0033] Embodiment 3: the preparation of metallic phase (1T) molybdenum disulfide / two-dimensional carbon nitride visible light composite photocatalyst comprises the following steps:

[0034] (1) Put melamine in a ceramic crucible with a cover, heat up to 550°C in a muffle furnace at a rate of 2°C / min and calcinate for 4h to obtain a yellow substance that is ground into powder, and then spread 500mg of the yellow powder on the ark In a muffle furnace, the temperature was raised to 550° C. for 1 h at a rate of 5° C. / min, and then the temperature was raised to 550° C. for 1 h at a rate of 2° C. / min to obtain two-dimensional carbon nitride.

[0035] (2) Add 30ml of dimethylformamide into the beaker, then add 100mg of carbon nitride, 0.0017g of molybdenum pentachloride, and 2.25g of thioacetamide into the beaker, stir for 30min, and disperse by ultrasonication for 30min.

[0036] (3) Transfer the mixed solution to a high-pressure reactor, and place the reactor in an oven at 200° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com