Allium chinense cutting machine

A cutting machine and buckwheat head technology, which is applied in the field of food manufacturing and processing, can solve the problems of inconvenient hand pinching, finger injury, slipping, etc., and achieve the effect of fast cutting and reducing the possibility of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

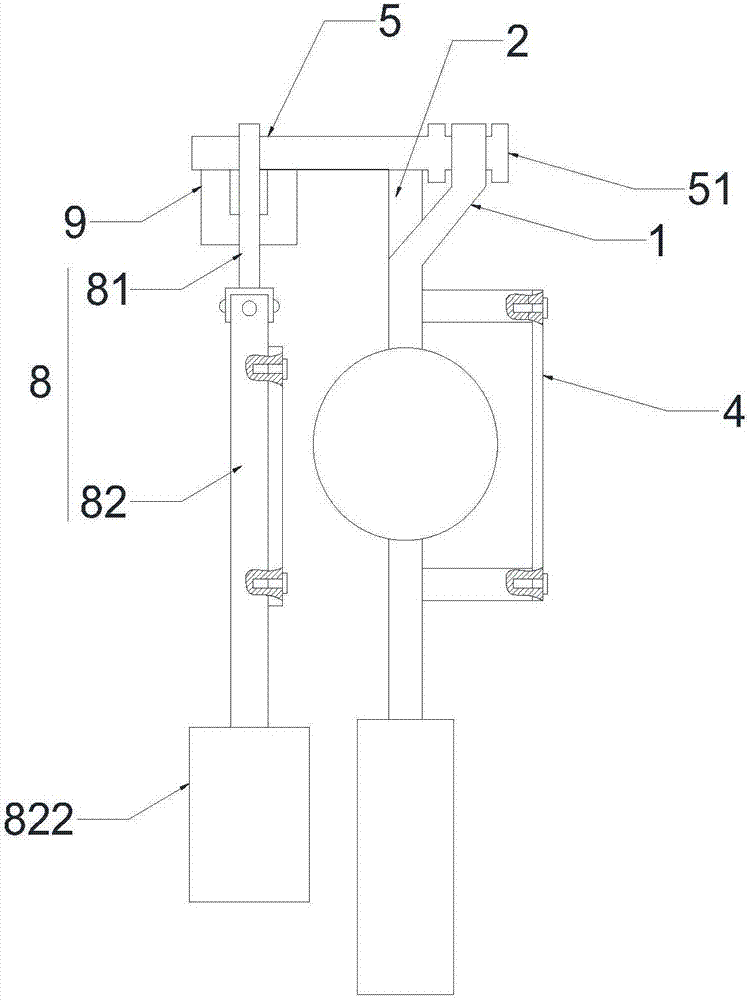

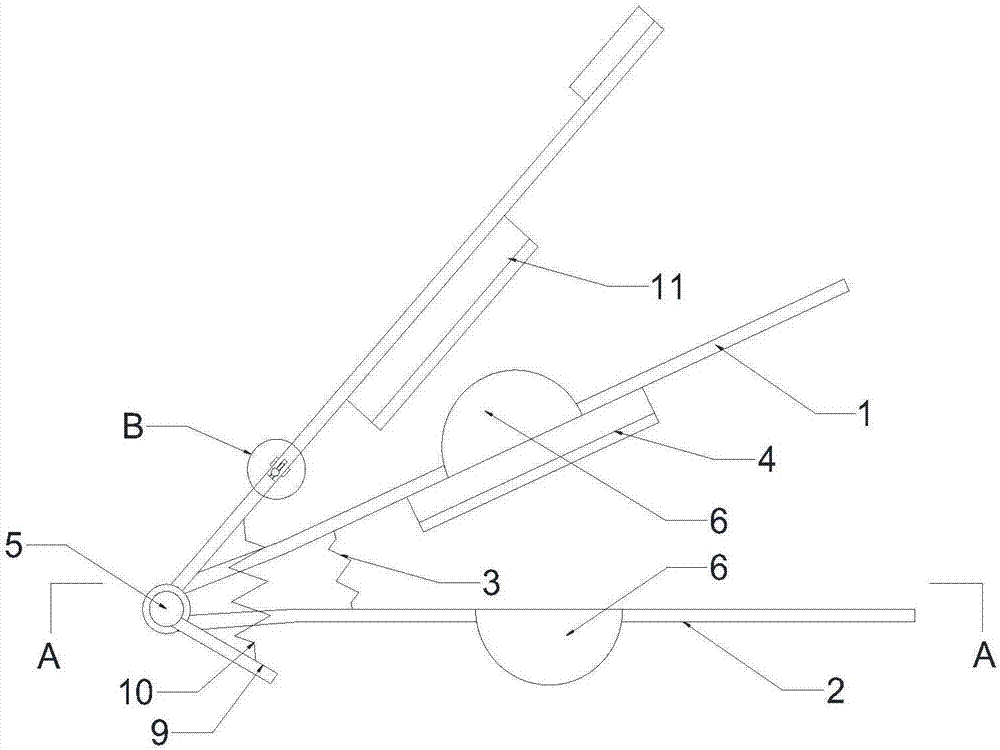

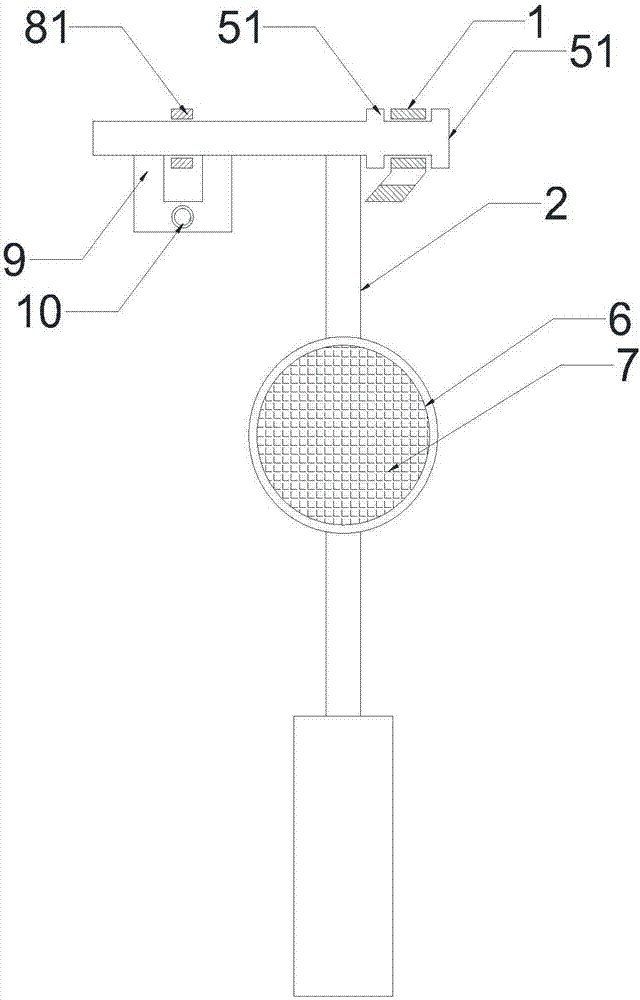

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the buckwheat cutting machine includes a first rod 1, a second rod 2, a first spring 3, a first blade 4, and a shaft rod 5; the middle part of the first rod 1 and the second rod 2 is provided with a groove 6; The groove 6 is provided with a sponge cushion 7; the first rod 1 is hinged with the shaft rod 5; the second rod 2 is fixedly connected with the shaft rod 5; Then, the grooves 6 on the first bar 1 and the second bar 2 are opposite; Parallel; the edge of the first blade 4 points to the second rod 2; the edge of the first blade 4 is opposite to the gap when the first rod 1 and the second rod 2 are closed. The buckwheat head is placed by setting the groove 6 on the first rod 1 and the second rod 2, and the buckwheat head is fixed by pressing, and the sponge cushion layer 7 is set in the groove 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com