Ultra abrasion resistant and adhesion resistant conveyer belt and preparation method thereof

An anti-adhesion and super wear-resistant technology, applied in the field of conveyor belts, can solve the problems of worn belts, decreased transportation efficiency, material accumulation on transportation lines, etc., to maximize service life, reduce cleaning costs, and improve transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

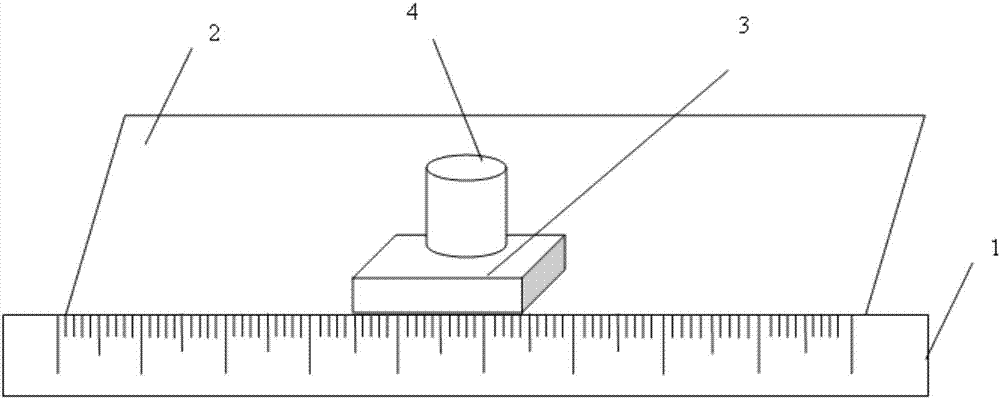

Image

Examples

Embodiment 1

[0028] 95 parts of butadiene rubber; 5 parts of natural rubber; 35 parts of carbon black N234; 25 parts of N115; 0.3 parts of sulfur; 2 parts of sulfenamide accelerator CZ; 1 part; 2 parts of anti-aging agent RD; 2 parts of anti-aging agent 4020NA; 2 parts of microcrystalline wax; 2 parts of dispersant FS-12;

[0029] The preparation method of the super wear-resistant anti-adhesion conveyor belt, the steps are as follows in parts by weight:

[0030] (1) One-stage mixing: put butadiene rubber and plastic-trained natural rubber into the internal mixer, mix at a speed of 30r / min for 80s; then add carbon black and continue mixing for 30s, then add vulcanization activator, Anti-aging agent, dispersant, softener, surface slipping agent, mixed for 2 minutes; the temperature is 130 ℃ deglue, parked for 18 hours, to obtain a section of mixed rubber;

[0031] (2) Two-stage mixing: Take the first-stage mixed rubber prepared in step (1), add anti-scorch agent CTP, vulcanizing agent sulfu...

Embodiment 2

[0037] 85 parts of butadiene rubber; 15 parts of natural rubber; 35 parts of carbon black N234; 25 parts of N115; 0.3 parts of sulfur; 2 parts of vulcanization accelerator accelerator NS; 1 part; 1.5 parts of anti-aging agent RD; 2 parts of anti-aging agent 4020NA; 1.5 parts of microcrystalline wax; 2 parts of dispersant AT-P;

[0038] The preparation method of the super wear-resistant anti-adhesion conveyor belt, the steps are as follows in parts by weight:

[0039] (1) One-stage mixing: put butadiene rubber and plastic-trained natural rubber into the internal mixer, and mix at a speed of 40r / min for 60s; then add carbon black and continue mixing for 40s, and then add vulcanization activator, Anti-aging agent, dispersant, softener, surface slipping agent, mixed for 1min; the temperature is 135°C, deglue, parked for 21 hours, to obtain a section of mixed rubber;

[0040] (2) Two-stage mixing: Take the first-stage mixed rubber prepared in step (1), add anti-scorch agent CTP, v...

Embodiment 3

[0046] 75 parts of butadiene rubber; 25 parts of natural rubber; 30 parts of carbon black N234; 20 parts of N115; 0.3 parts of sulfur; 2 parts of vulcanization accelerator DTDM; 2 parts of anti-aging agent RD; 1.5 parts of anti-aging agent 4020NA; 1.5 parts of microcrystalline wax; 1.5 parts of dispersant AT-P;

[0047] The preparation method of the super wear-resistant anti-adhesion conveyor belt, the steps are as follows in parts by weight:

[0048] (1) One-stage mixing: put butadiene rubber and plastic-trained natural rubber into the internal mixer, mix at a speed of 50r / min for 40s; then add carbon black and continue mixing for 30s, then add vulcanization activator, Anti-aging agent, dispersant, softener, surface slipping agent, mixed for 1min; the temperature is 140 ℃ deglue, parked for 18 to 24 hours, to obtain a mixed rubber;

[0049](2) Two-stage mixing: Take the first-stage mixed rubber prepared in step (1), add anti-scorch agent CTP, vulcanizing agent sulfur, and vu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com