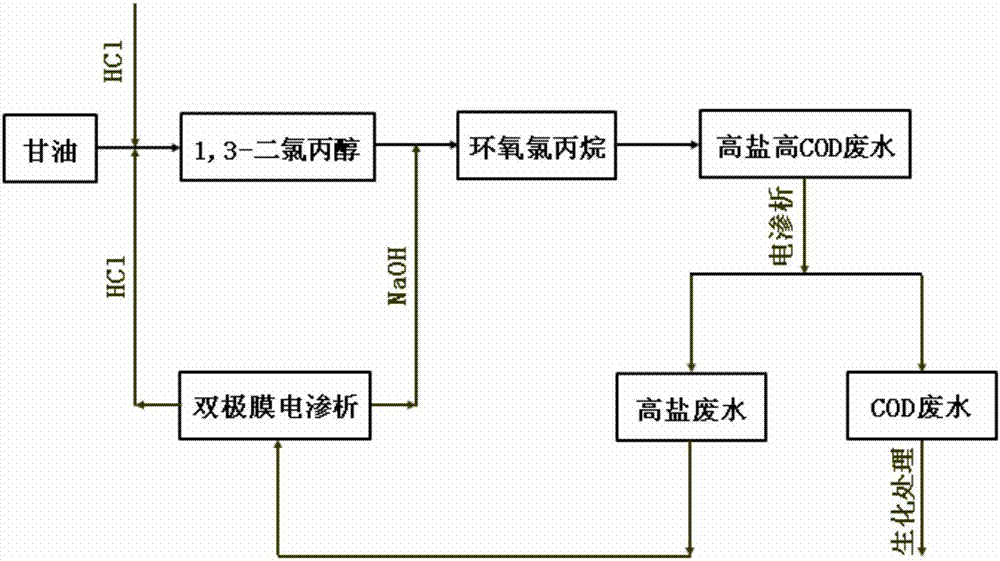

Clean process for preparing epoxy chloropropane by zero discharge glycerin method

An epichlorohydrin, zero-emission technology, applied in the field of cleaning processes, can solve the problems of salt deposition in biochemical systems, deterioration of sludge performance, and high cost, and achieve the effect of huge application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (laboratory scale)

[0031] In a 500ml four-necked flask, add 200g of glycerol, catalyzer (anhydrous acetic acid) 16g, put the stirrer in the mouth of the center, put the thermometer in the side mouth, and the other two mouths are the inlet pipe and the outlet of HCl respectively. React at about 100°C until the amount of HCl gas evolution no longer changes. The reaction yielded a yellow liquid product, which was evaporated to remove water and catalyst on a rotary evaporator to obtain relatively pure 1,3-dichloro-2-propanol (238 g, yield about 85%).

[0032] Mix 1,3-dichloro-2-propanol with NaOH solution (420g solution, 20wt.%), cyclization reaction occurs at about 70°C to generate epichlorohydrin, then distill to obtain crude epichlorohydrin, and rectify to obtain Pure epichlorohydrin (162 g, about 95% yield).

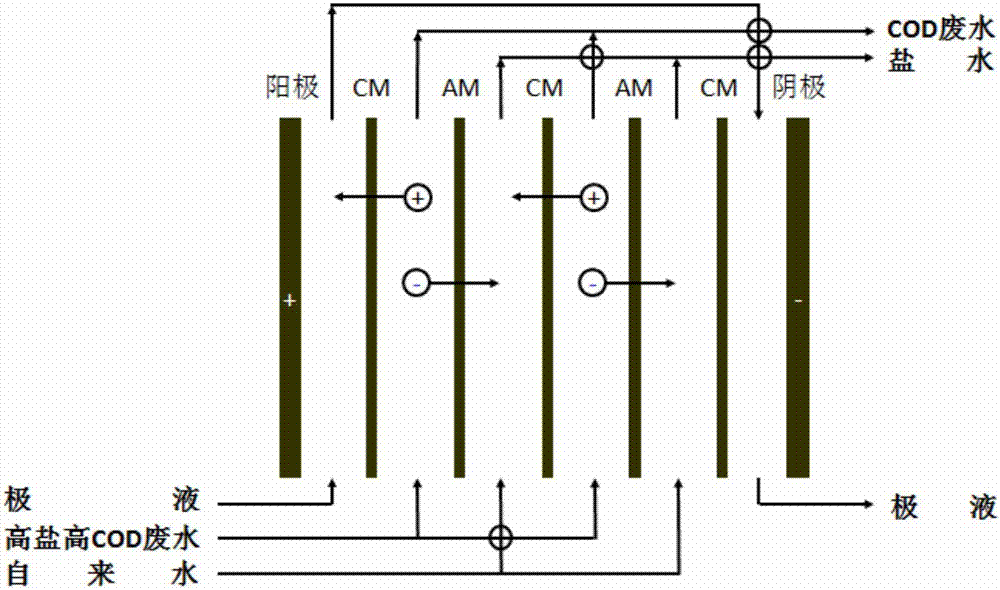

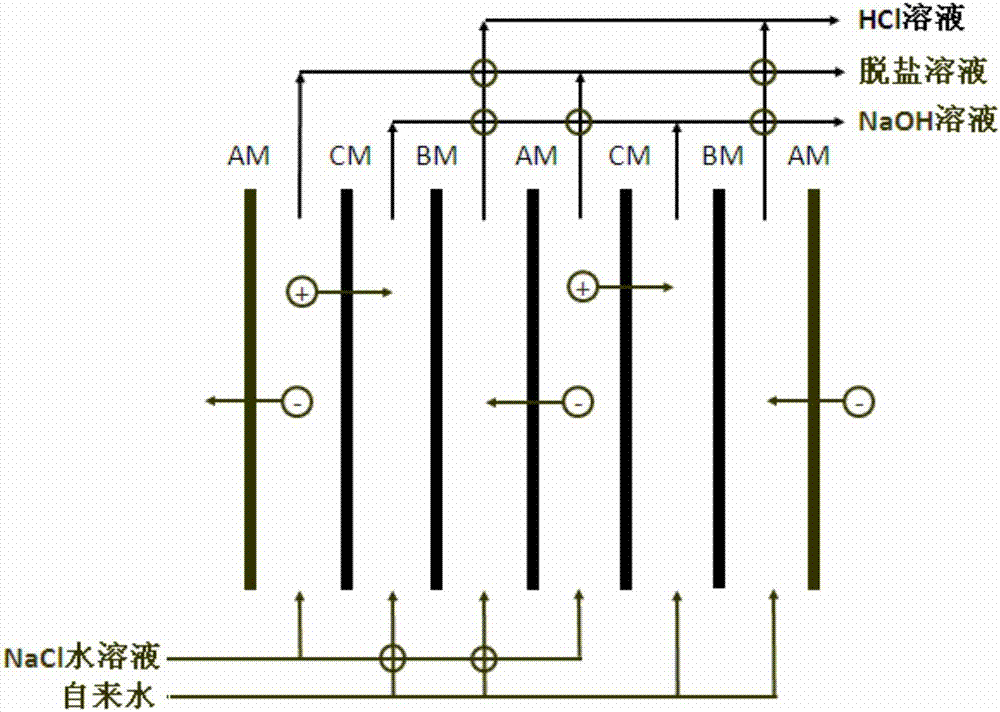

[0033] Add hydrochloric acid into the cyclization wastewater (adding a small amount can remove the excess NaOH in the cyclization reaction and th...

Embodiment 2

[0037] Embodiment 2 (industrial scale, epichlorohydrin output is 10kt / y)

[0038] Glycerin 1555kg / h from the glycerin storage tank is preheated by the glycerin preheater and then enters the chlorination reactor; HCl gas 1666kg / h from the hydrochloric acid synthesis unit is passed into the chlorination reactor for chlorination reaction, and the reaction temperature is 90-105°C , the reaction pressure is a slight positive pressure. In the early stage of the reaction, steam should be passed into the interlayer of the reaction kettle for heating. temperature.

[0039] After the reaction is finished, the reactant dichloropropanol is distilled by means of external circulation heating, and the steamed crude dichloropropanol (containing about 1854kg / h of dichloropropanol) is transported to the transfer tank through a pump, and the excess HCl gas is pumped into another tank. The glycerol in the chlorination reactor is absorbed, and the HCl that is still not fully reacted enters the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com