Low-cost water treatment and recycling method for high-salinity gas field

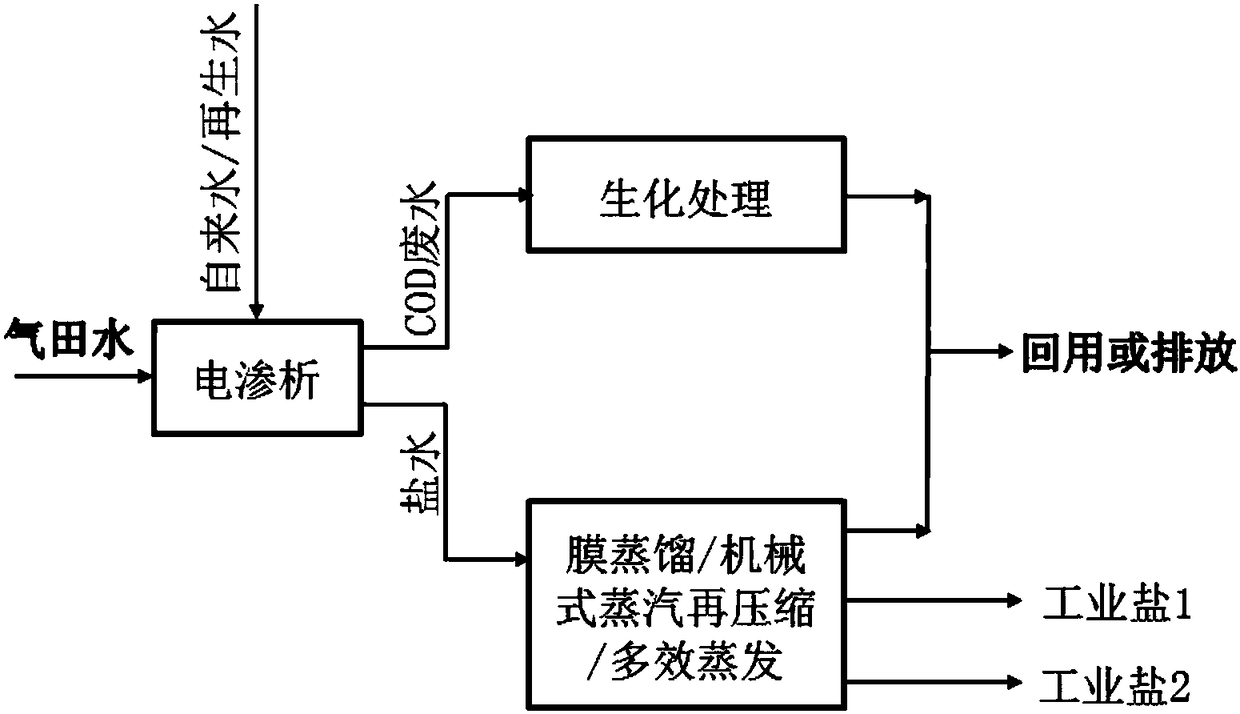

A technology of gas field water and high salt content, applied in the field of electrodialysis desalination, can solve the problems of difficulty in finding re-injection wells, high cost, affecting the development of new gas fields, etc., and achieve the effect of huge application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

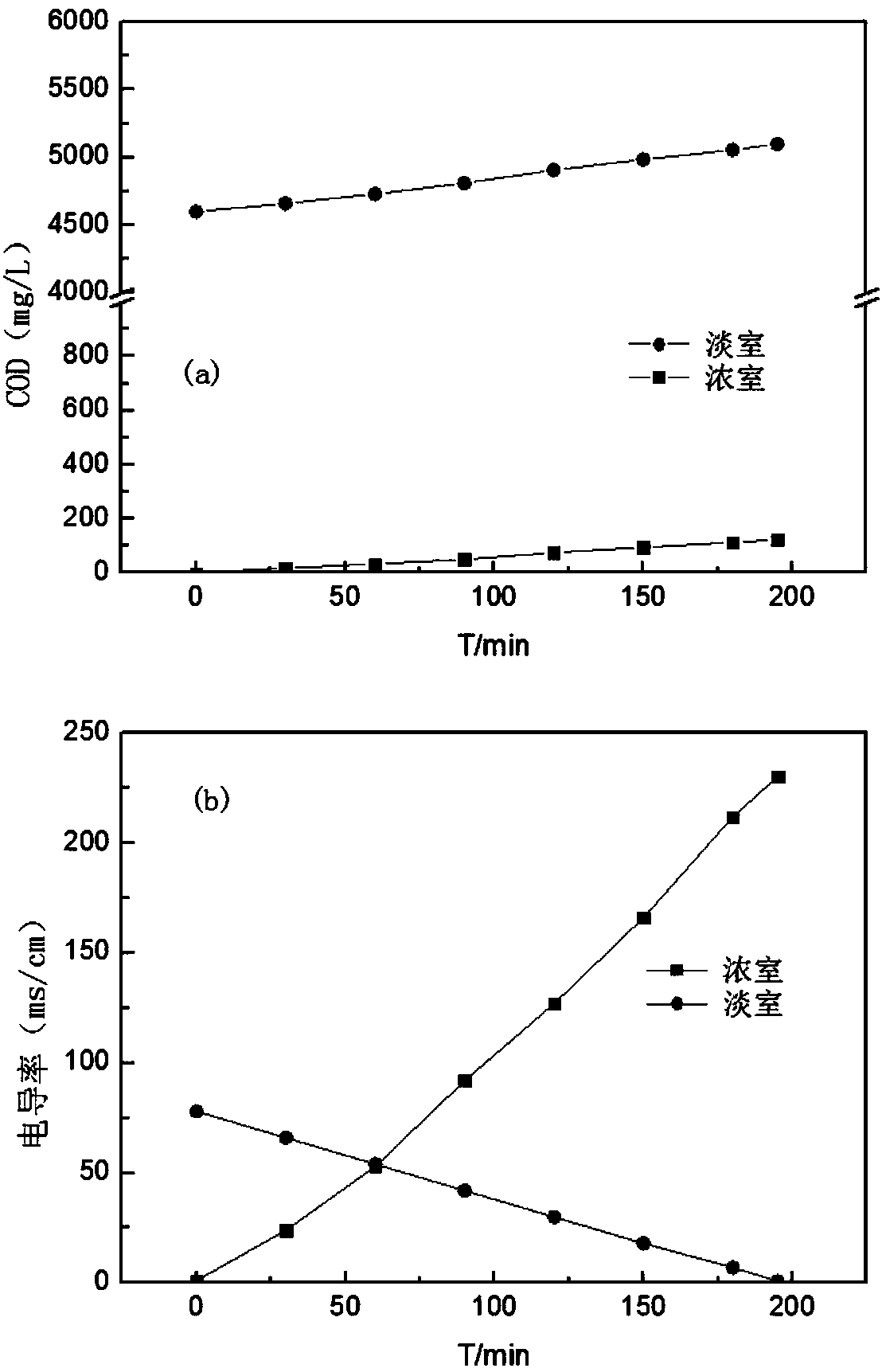

[0034] Embodiment 1 (high-salt high-COD gas field water)

[0035] The composition of gas field water is: NaCl content 5.2wt.%, COD 4600mg / L.

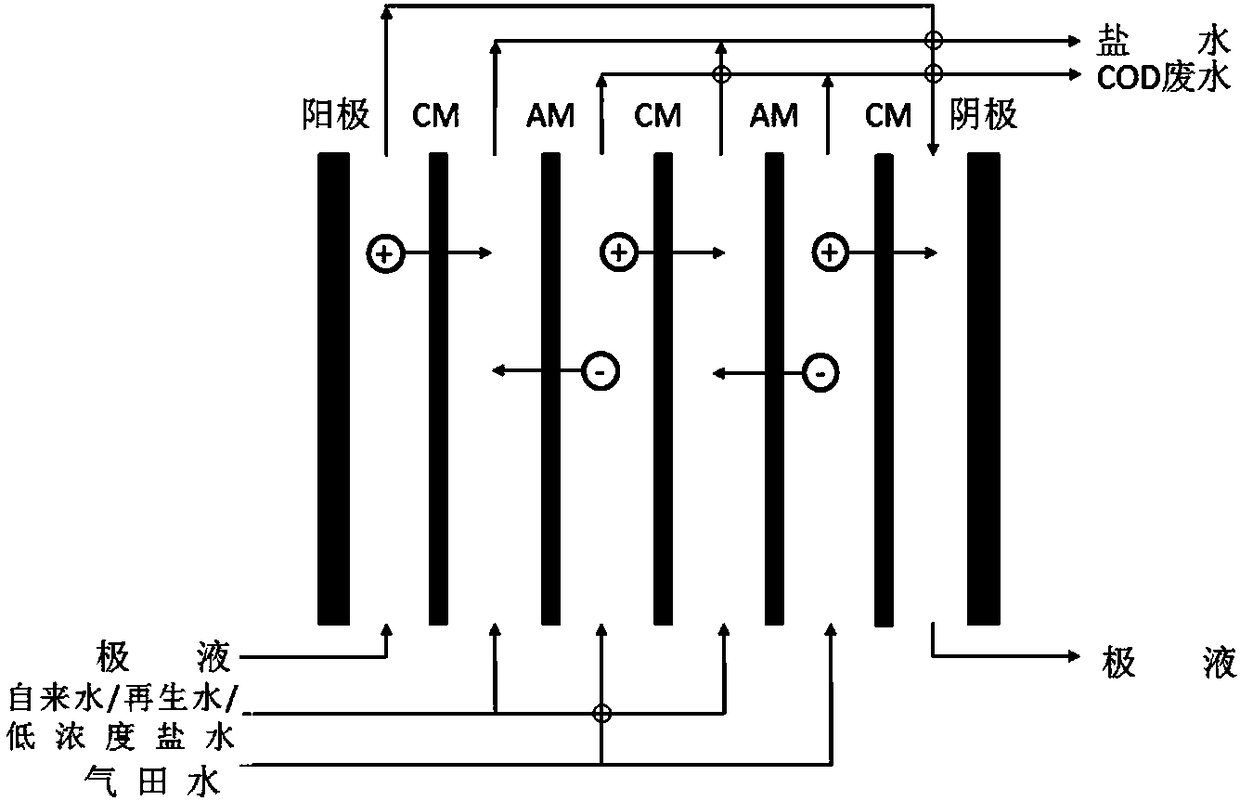

[0036] The electrodialyzer includes a pair of positive and negative plates, 2 anion exchange membranes, 3 cation exchange membranes, 2 separators between the cation exchange membrane and the plates, and 4 flow channels between the anion exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130mm and a resistance of 9.9Ω.cm 2 , the water content is 25%; the anion membrane is a quaternary ammonium type homogeneous anion exchange membrane, the thickness is about 0.150mm, and the resistance is 11.6Ω.cm 2 , the water content is 35%; the area of a single membrane is about 0.03m 2 . The thickness of the separator and flow channel is about 0.5mm, with 0.1M Na 2 SO 4 The solution is polar liquid, a voltage of 1.12V is applied between the two plates of the electro...

Embodiment 2

[0039] Example 2 (gas field water with high salt and easy scaling, nanofiltration-electrodialysis)

[0040] The composition of gas field water is: NaCl content 5.8wt.%, CaSO 4 Content 1.36g / L.

[0041] The operating pressure of the nanofiltration membrane separator is 12bar, and the effective membrane area is 214.5cm 2 , the recovery rate is about 76%. After nanofiltration, gas field water becomes retentate and permeate, the composition of which is shown in Table 1.

[0042] The electrodialyzer includes a pair of positive and negative plates, 10 anion exchange membranes, 11 cation exchange membranes, 2 separators between the cation exchange membrane and the plates, and 20 flow channels between the anion exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130mm and a resistance of 9.9Ω.cm 2 , the water content is 25%; the anion membrane is a quaternary ammonium type homogeneous anion exchange mem...

Embodiment 3

[0047] Embodiment 3 (low COD-divalent ion wastewater)

[0048] The composition of gas field water is: NaCl content 6.6wt.%, MgCl 2 Content 3.9wt.%.

[0049] The electrodialyzer includes a pair of positive and negative plates, 11 cation exchange membranes, 11 bivalent selective cation exchange membranes, 10 anion exchange membranes, 2 separators between the ion exchange membrane and the plates, cation exchange 11 flow channels between the membrane and a divalent selective cation exchange membrane, 10 flow channels between a divalent selective cation exchange membrane and an anion exchange membrane, and 10 flow channels between a cation exchange membrane and an anion exchange membrane 10. The positive membrane is a heterogeneous cation exchange membrane with a thickness of about 0.40mm and a resistance of 30Ω.cm 2 , with a moisture content of 40%; the first and second valence selective cation exchange membranes are commercial products with a thickness of about 0.2mm and a res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com