A low-cost treatment and resource utilization method for high-salt gas field water

A gas field water and high salt content technology, applied in the field of electrodialysis desalination, can solve the problems of difficulty in finding reinjection wells, high cost, and affecting the production of established gas fields, and achieves the effect of huge application potential and solving the problem of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

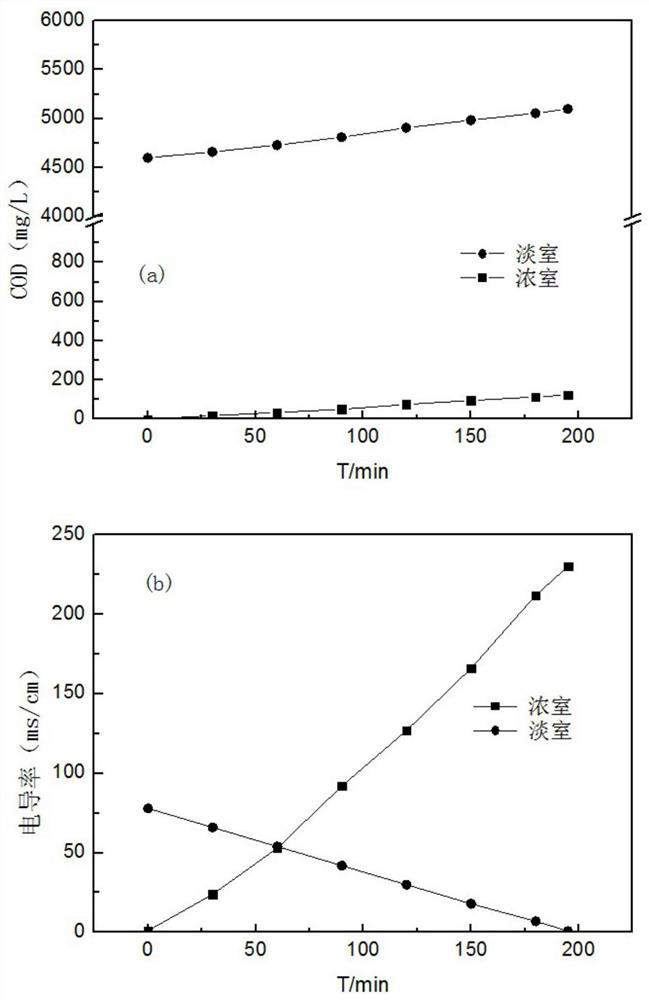

[0035] Example 1 (high-salt and high-COD gas field water)

[0036] The gas field water composition is as follows: NaCl content 5.2 wt.%, COD 4600 mg / L.

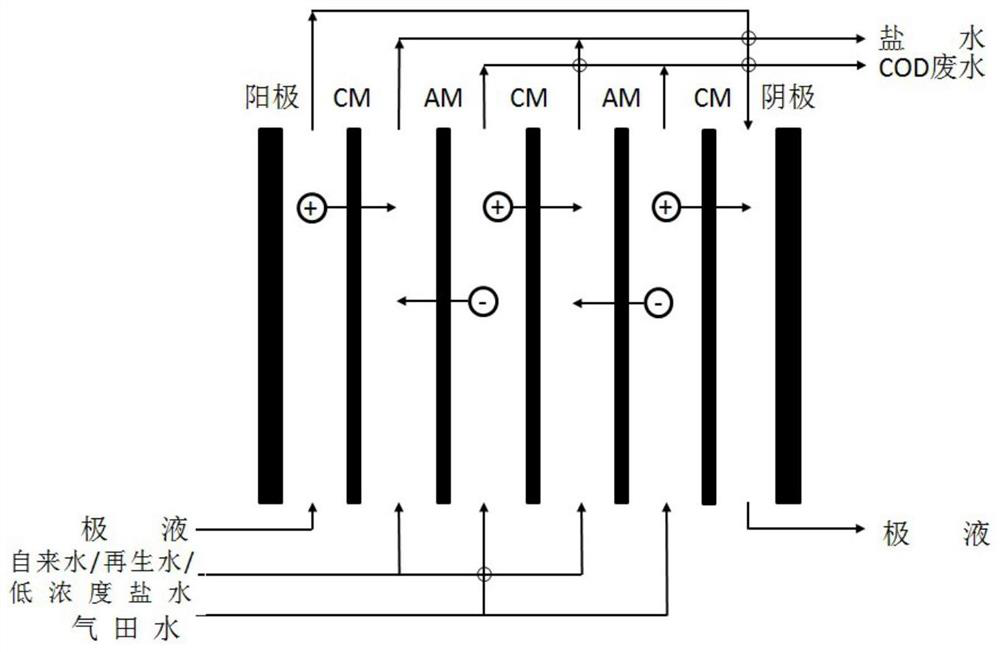

[0037] The electrodialyzer includes a pair of positive and negative plates, 2 anion exchange membranes, 3 cation exchange membranes, 2 separators between the cation exchange membrane and the plates, and 4 flow channels between the anion exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130 mm and a resistance of 9.9 Ω.cm 2 , with a water content of 25%; the anion membrane is a quaternary ammonium type homogeneous anion exchange membrane with a thickness of about 0.150 mm and a resistance of 11.6 Ω.cm 2 , the water content is 35%; the area of a single membrane is about 0.03 m 2 . The thickness of the separator and flow channel is about 0.5 mm, with 0.1 M Na 2 SO 4 The solution is polar liquid, a voltage of 1.12 V is applied between the two ...

Embodiment 2

[0040] Example 2 (high-salt gas field water prone to fouling, nanofiltration-electrodialysis)

[0041] The composition of gas field water is: NaCl content 5.8 wt.%, CaSO 4 The content is 1.36 g / L.

[0042] The operating pressure of the nanofiltration membrane separator is 12 bar, and the effective membrane area is 214.5 cm 2 , The recovery rate is about 76%. After nanofiltration, gas field water becomes retentate and permeate, the composition of which is shown in Table 1.

[0043] The electrodialyzer includes a pair of positive and negative plates, 10 anion exchange membranes, 11 cation exchange membranes, 2 separators between the cation exchange membrane and the plates, and 20 flow channels between the anion exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130 mm and a resistance of 9.9 Ω.cm 2 , with a water content of 25%; the anion membrane is a quaternary ammonium type homogeneous anion e...

Embodiment 3

[0048] Embodiment 3 (low COD-divalent ion wastewater)

[0049] The gas field water composition is as follows: NaCl content 6.6 wt.%, MgCl 2 Content 3.9 wt.%.

[0050] The electrodialyzer includes a pair of positive and negative plates, 11 cation exchange membranes, 11 bivalent selective cation exchange membranes, 10 anion exchange membranes, 2 separators between the ion exchange membrane and the plates, cation exchange 11 flow channels between the membrane and a divalent selective cation exchange membrane, 10 flow channels between a divalent selective cation exchange membrane and an anion exchange membrane, and 10 flow channels between a cation exchange membrane and an anion exchange membrane 10. The positive membrane is a heterogeneous cation exchange membrane with a thickness of about 0.40 mm and a resistance of 30 Ω.cm 2 , with a moisture content of 40%; the first and second valence selective cation exchange membranes are commercial products with a thickness of about 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com