Matte finishing varnish

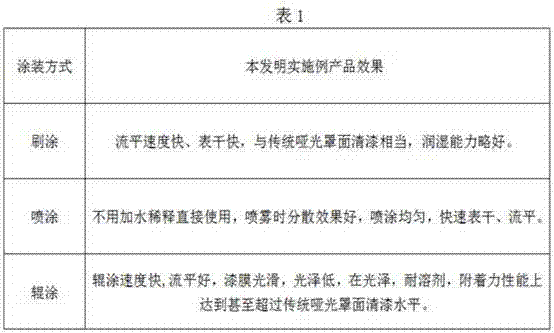

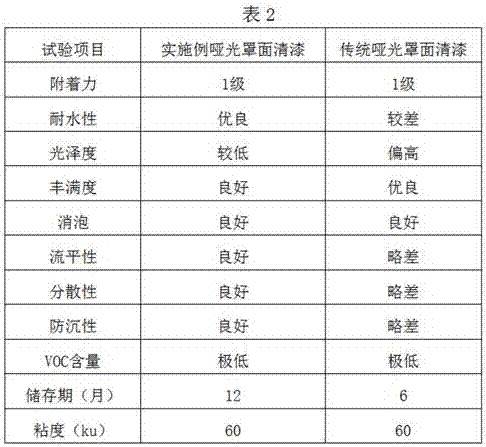

A finishing varnish and matte technology, applied in the direction of coating, etc., can solve the problems of not easy to form stratification and precipitation, whitening, matte powder and easy to mold, etc., and achieve good wetting ability, good storage stability and glossiness good low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A matte finish varnish, comprising the following components in parts by mass:

[0023] Water-Based Acrylic Matte Lotion 50 parts,

[0024] 30 parts of deionized water,

[0025] Substrate wetting agent 0.05 parts,

[0026] 0.1 part of defoamer,

[0027] 1 part propylene glycol,

[0028] 1 part of film-forming aid,

[0029] Thickener 0.2 parts.

[0030] In this example, the water-based acrylic emulsion used is CAP-4800 from Japan Showa, the substrate wetting agent used is one or a combination of 2432 from Haichuan Chemical Industry and BYK-033 from BYK, and the defoamer used is BASF For A10, the propylene glycol used is Sinopec’s propylene glycol, the film-forming aid used is American Eastman’s Alcohol Fat 12, and the thickener used is one or both of Rohm and Haas’s TT-935 and RM-8W The combination.

[0031] The preparation method of the present embodiment matte finish varnish comprises the steps:

[0032] (1) According to the above-mentioned component distributio...

Embodiment 2

[0036] A matte finish varnish, comprising the following components in parts by mass:

[0037] Waterborne Acrylic Matte Lotion 60 parts,

[0038] 46 parts of deionized water,

[0039] Substrate wetting agent 0.1 parts,

[0040] 0.2 part of defoamer,

[0041] 2 parts of propylene glycol,

[0042] 2 parts of film-forming aids,

[0043] Thickener 0.4 parts.

[0044] In this example, the water-based acrylic emulsion used is CAP-4800 from Japan Showa, the substrate wetting agent used is one or a combination of 2432 from Haichuan Chemical Industry and BYK-033 from BYK, and the defoamer used is BASF For A10, the propylene glycol used is Sinopec’s propylene glycol, the film-forming aid used is American Eastman’s Alcohol Fat 12, and the thickener used is one or both of Rohm and Haas’s TT-935 and RM-8W The combination.

[0045] The preparation method of the matte finish varnish of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0047] A matte finish varnish, comprising the following components in parts by mass:

[0048] Waterborne Acrylic Matte Lotion 55 parts,

[0049] 38 parts of deionized water,

[0050] Substrate wetting agent 0.08 parts,

[0051] 0.15 part of defoamer,

[0052] 1.5 parts of propylene glycol,

[0053] 1.5 parts of film-forming aids,

[0054] Thickener 0.3 part.

[0055] In this example, the water-based acrylic emulsion used is CAP-4800 from Showa Japan, the substrate wetting agent used is one or a combination of 2432 from Haichuan Chemical Industry and BYK-033 from BYK, and the defoamer used is BASF For A10, the propylene glycol used is Sinopec’s propylene glycol, the film-forming aid used is American Eastman’s Alcohol Fat 12, and the thickener used is one or both of Rohm and Haas’s TT-935 and RM-8W The combination.

[0056] The preparation method of the matte finish varnish of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com