Preparation method of nickel and aluminum-based multiphase alloy

A nickel-aluminum-based and alloy technology, applied in the chemical industry, can solve the problems of inability to obtain nickel-aluminum-based composite alloy blocks, poor fluidity, and difficulty in filling, and achieves overcoming a large number of irregular edges and corners, reducing risks, and internal density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Taking the preparation of a nickel-aluminum-based multiphase alloy with a component content of 30% nickel and 70% aluminum as an example, the following steps are included:

[0045] (1) Mold loading: Assemble a metal mold with a diameter of 5mm and a length of 5mm in the negative pressure suction casting system in the vacuum electric arc furnace;

[0046] (2) Sample loading: start the vacuum electric arc furnace, put high-purity Ni and high-purity Al (>99.9wt.%) with a nominal composition of 70Al-30Ni into the crucible of the vacuum electric arc furnace;

[0047] (3) Vacuuming: Open the vacuum valve and vacuumize until the vacuum degree is 2.0×10 -3 MPa, then tighten the vacuum valve;

[0048] (4) Gas filling: Pour argon gas into the sample chamber of the vacuum electric arc furnace until the vacuum degree is 0.5MPa;

[0049] (5) Repeat steps 3 to 4;

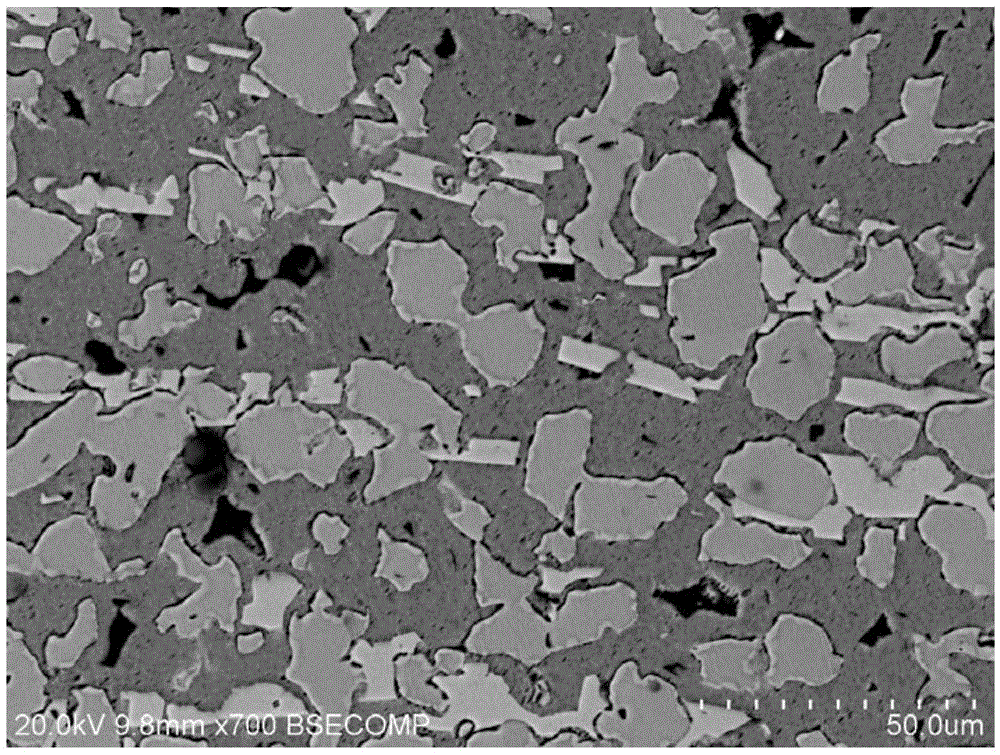

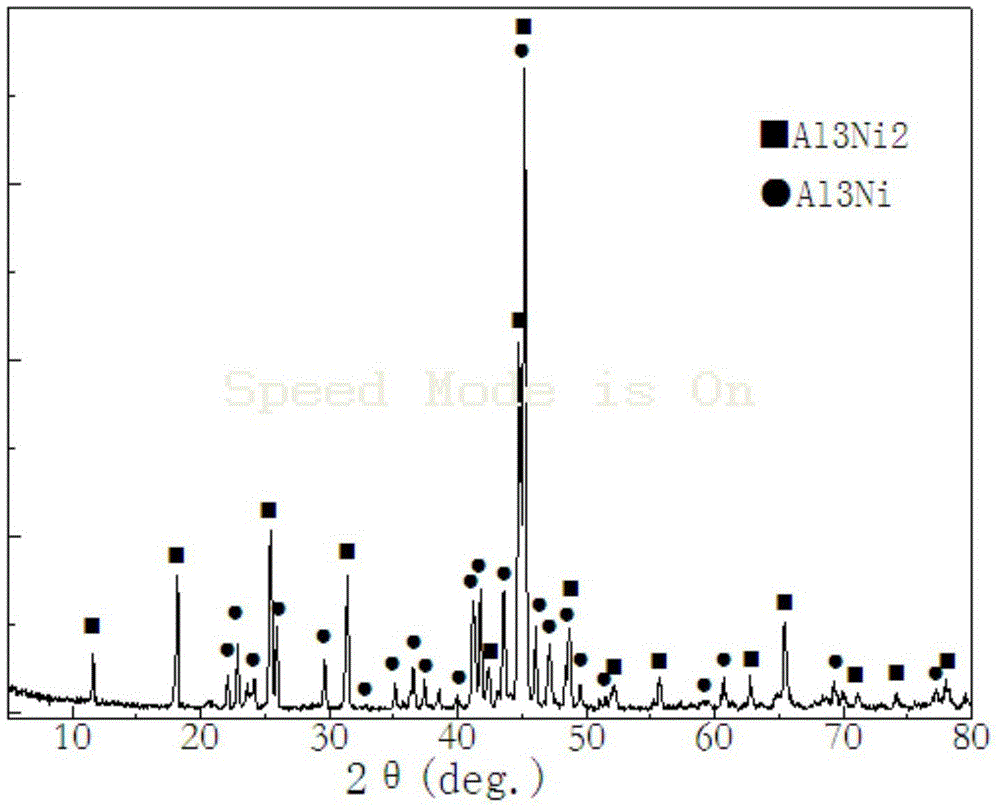

[0050] (6) The vacuum electric arc furnace is energized to melt Ni and Al, and continues to heat until the metal is m...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is that the component content in the nickel-aluminum base multiphase alloy is 65% nickel and 35% aluminum, and the vacuum degree in step 3 is 5.0×10 -3 MPa, in step 4 and step 8, argon gas is flushed until the vacuum degree is 0.65MPa, in step 6, the heating temperature is 1620°C, in step 7, keep warm for 2 minutes, the output current of magnetic stirring is 15A, and suction cast into a regular block of φ15mm×15mm body.

[0057] The microstructure and phase analysis of the nickel-aluminum-based multiphase alloy prepared in this example are consistent with the results of Example 1, and will not be repeated here.

Embodiment 3

[0059] The difference between this embodiment and embodiment 1 is that the component content in the nickel-aluminum base multiphase alloy is 67% nickel and 33% aluminum, and the vacuum degree in step 3 is 3.0×10 -3 MPa, in step 4 and step 8, argon gas is flushed until the vacuum degree is 0.55MPa, in step 6, the heating temperature is 1610°C, in step 7, the temperature is kept for 1.5min, the output current of magnetic stirring is 10A, and the suction casting is φ12mm×12mm blocks.

[0060] The microstructure and phase analysis of the nickel-aluminum-based multiphase alloy prepared in this example are consistent with the results of Example 1, and will not be repeated here.

[0061] In summary, the nickel-aluminum-based multiphase alloy is prepared by the present invention, the raw material is not powder, the incidence of safety accidents is reduced, and the surface quality of the nickel-aluminum-based multiphase alloy is good, the size and shape of the block are regular, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com