Rock burst preventing method for blast and injection of water-coupled softened coal body

A technology for impacting rock pressure and coal mass, which is used in surface mining, earth-moving drilling, underground mining, etc. It can solve the problems of insufficient pressure relief effect, water injection effect, high impact risk, and easy water injection softening. , The pressure relief effect is good, and the water injection resistance is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

[0020] A method for preventing and controlling rock burst by coupling softening of coal body with blasting and water injection comprises the following steps.

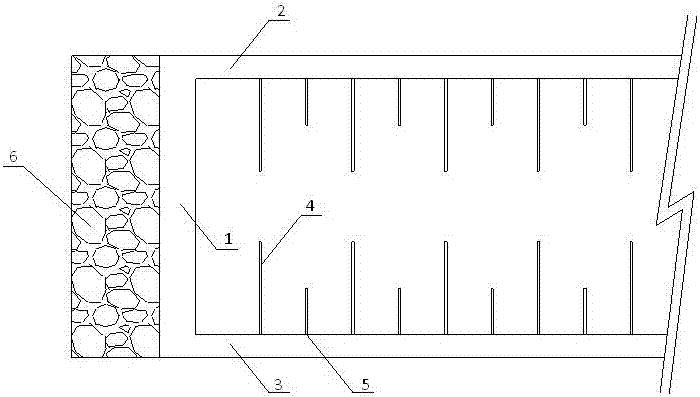

[0021] Step 1, laying out water injection holes: on the upper side of the upper lane and the upper side of the lower lane in the coal mining face of the coal mine, such as figure 1 As shown, several vertical water injection holes are evenly arranged along the propulsion direction.

[0022] The construction spacing of the water injection holes is preferably 20-30m, and the depth of the water injection holes is preferably 20-30m.

[0023] Step 2, arranging blast holes: a blast hole vertical to the side of the road is arranged in the middle between the two adjacent water injection holes of the lower side of the upper road and the upper side of the lower road, and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com