Intelligent monitoring system for high and low temperature heat exchange in dilute acid concentrating process

An intelligent monitoring, high and low temperature technology, applied to the parts of thermometers, thermometers, measuring devices, etc., can solve problems such as high production costs, heat exchanger blockage, and no monitoring of intake air temperature, and achieve the effect of industrial production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

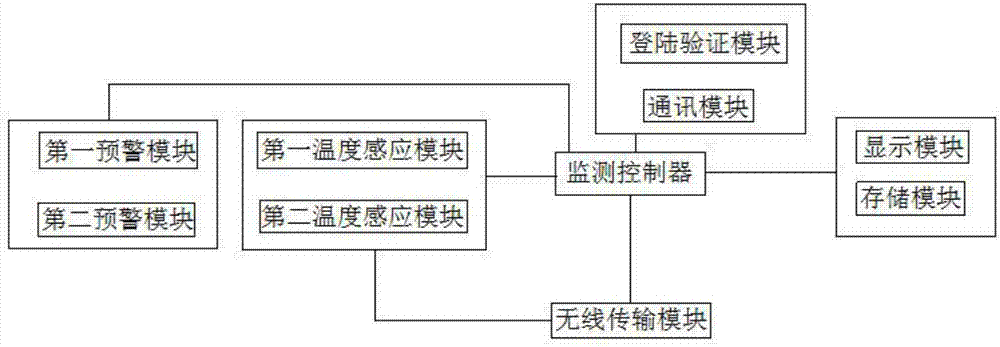

[0023] see figure 1 , an intelligent monitoring system for high and low temperature heat exchange in the dilute acid concentration process, including a monitoring controller, a first temperature sensing module, a second temperature sensing module, a storage module, a wireless transmission module, a first early warning module, a second Early warning module, display module, login verification module and communication module;

[0024] The monitoring controller, located in the general control, is responsible for receiving information sent by other modules in the system, setting the temperature threshold at the inlet and exhaust ports of the heat exchanger, and sending the first warning module and the second warning module to the first warning module and the second warning module according to the received information. A warning message is issued; a display module is connected to the monitoring controller, and the display module is responsible for displaying temperature information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com