Remote integrated control system for industrial 4.0 coal-fired flue gas pollution control facility

A coal-fired flue gas and pollution control technology, which is applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problems of not being able to analyze potential problems in time, increasing operating costs, and not being able to check the operation status of each project in real time. , to achieve the effect of saving personnel expenses, reducing operating costs and reducing staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

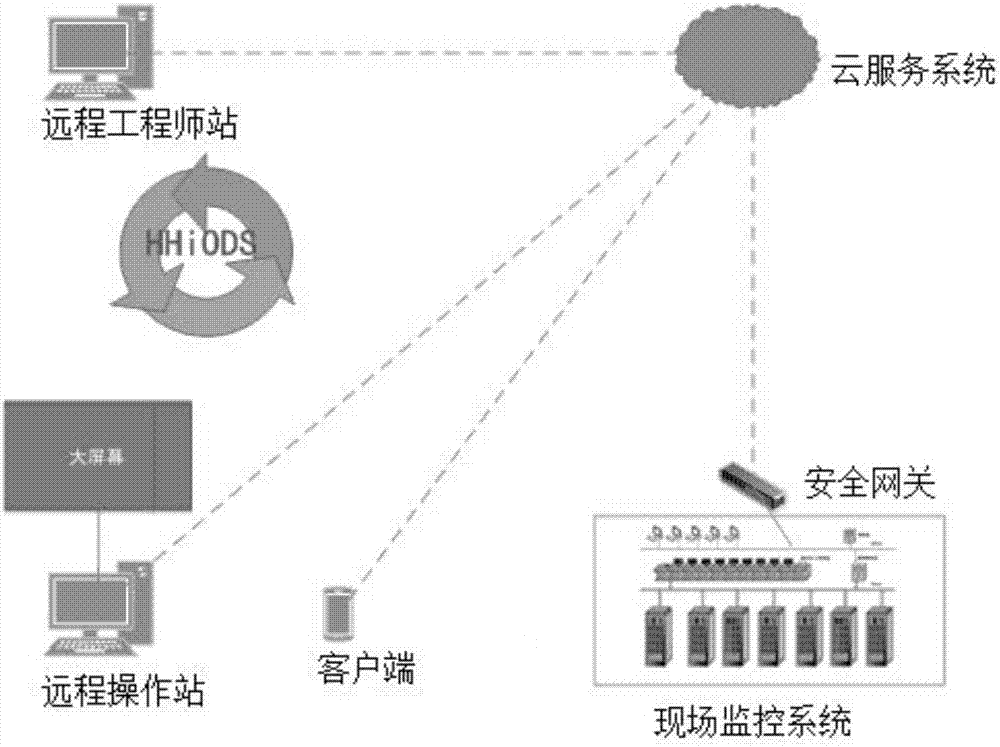

[0036] Such as figure 1 As shown, the remote integrated control system of industrial 4.0 coal-fired flue gas pollution control facilities, including

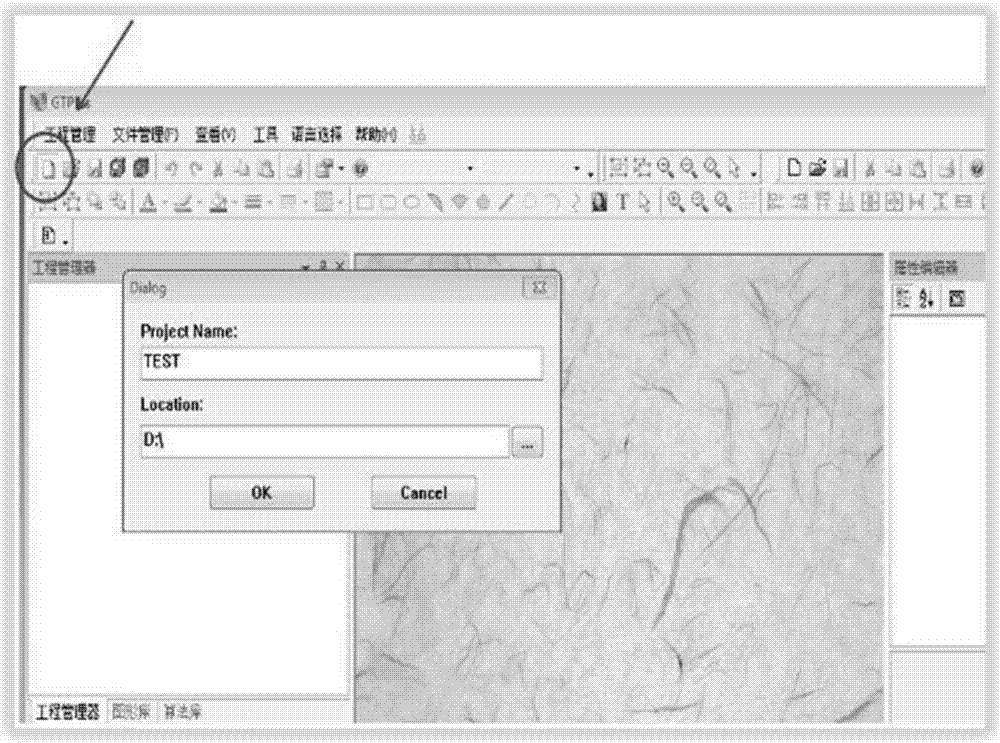

[0037] Remote engineer station for completing system database, history library, graphics, control language configuration and downloading functions; and,

[0038] A remote operation station for calling and displaying configuration graphics, displaying real-time data and status on site, displaying historical data, and completing control adjustment, trend display, and alarm display functions; and,

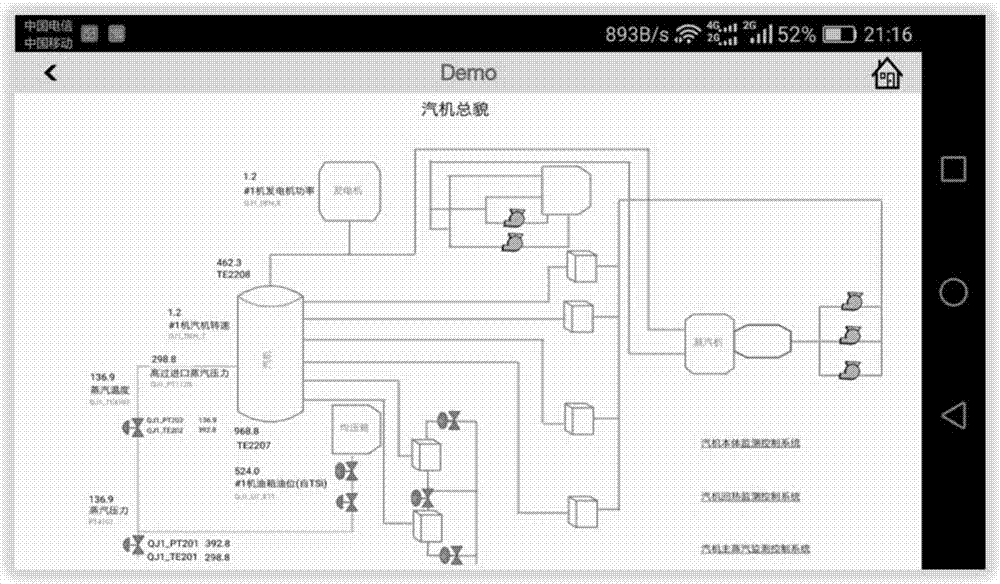

[0039] A client for invoking and displaying configured graphics, displaying on-site real-time data, device status, trend display, and alarm display functions; and,

[0040] A cloud service system for fulfilling client data requests and real-time data push tasks; and,

[0041] An on-site monitoring system for monitoring various types of equipment on site; and,

[0042]It is used to realize the communication with various fieldbus instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com