Graphene oxide/silver phosphate composite photocatalyst as well as preparation method and application thereof

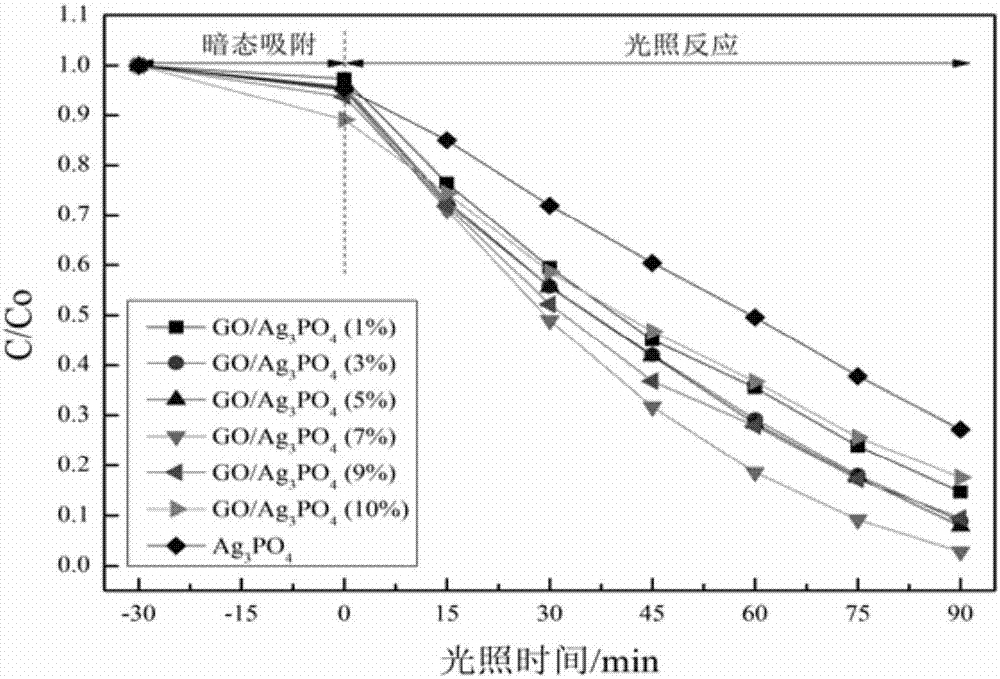

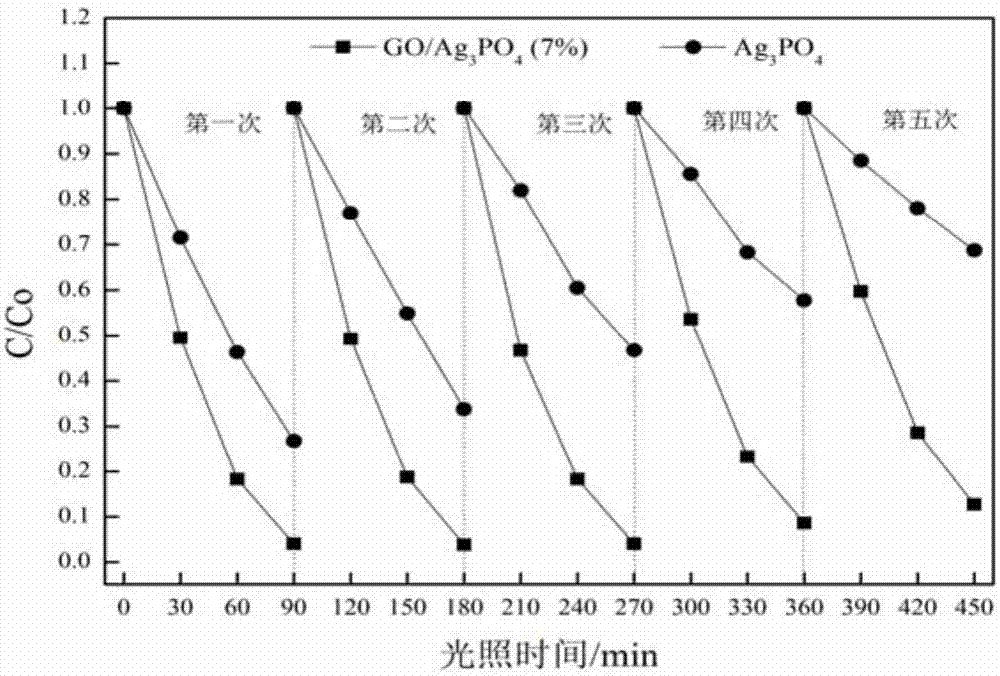

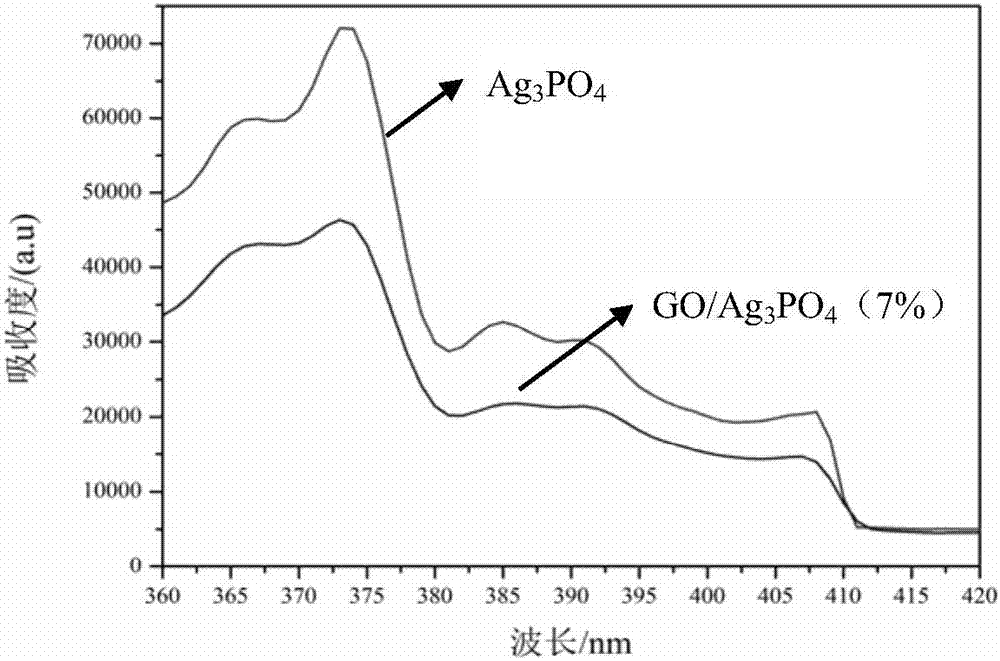

A silver phosphate, composite light technology, applied in the field of photocatalytic materials, can solve the problems of reducing structural stability, photocorrosion, etc., and achieve the effects of good stability, great development and application prospects, and good photocatalytic degradation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Measure 3 mL of GO solution with a concentration of 1 mg / mL in 10 mL of water, and ultrasonically disperse for 30 min in an ultrasonicator with P=100 W to obtain a GO dispersion;

[0032] (2) Weigh 1.02g AgNO 3 Dissolved in 10mL of water, then added dropwise to the GO dispersion in step (1), at a rate of 25 drops / min, and stirred for 1h (400r / min) in the dark at room temperature to obtain a mixed dispersion;

[0033] (3) Weigh 0.716g Na 2 HPO 4 12H 2 O was dissolved in 20mL of water, then added dropwise to the mixed dispersion in step (2), at a rate of 25 drops / min, and stirred for 4h (400r / min) in the dark at room temperature to form a precipitate;

[0034] (4) The precipitate obtained in step (3) was centrifuged, washed repeatedly with distilled water for 3 times, and dried in vacuum at 60°C for 12 hours to obtain GO / Ag 3 PO 4 (Because there will be mass loss in the actual preparation, by calculating the weight of GO as Ag 3 PO 4 1% by weight (w=1%) composi...

Embodiment 2

[0036] (1) Measure 9 mL of GO solution with a concentration of 1 mg / mL in 10 mL of water, and sonicate for 40 min in an ultrasonicator with P=100 W until GO is completely dispersed in water to obtain a GO dispersion;

[0037] (2) Weigh 1.02g AgNO3 Dissolved in 10mL of water, then added dropwise to the GO dispersion in step (1), at a rate of 25 drops / min, and stirred for 1h (400r / min) in the dark at room temperature to obtain a mixed dispersion;

[0038] (3) Weigh 0.716g Na 2 HPO 4 12H 2 O was dissolved in 20mL of water, then added dropwise to the mixed dispersion in step (2), at a rate of 25 drops / min, and stirred for 4h (400r / min) in the dark at room temperature to form a precipitate;

[0039] (4) The precipitate obtained in step (3) was centrifuged, washed repeatedly with distilled water 4 times, and dried in vacuum at 65°C for 12 hours to obtain GO / Ag 3 PO 4 (The weight of GO is Ag 3 PO 4 3% by weight (w=3%) composite photocatalyst namely GO / Ag 3 PO 4 (3%).

Embodiment 3

[0041] (1) Measure 15 mL of GO solution with a concentration of 1 mg / mL in 10 mL of water, and sonicate for 40 min in an ultrasonicator with P=100 W until GO is completely dispersed in water to obtain a GO dispersion;

[0042] (2) Weigh 1.02g AgNO 3 Dissolved in 10mL of water, then added dropwise to the GO dispersion in step (1), at a rate of 25 drops / min, and stirred for 1h (400r / min) in the dark at room temperature to obtain a mixed dispersion;

[0043] (3) Weigh 0.716g Na 2 HPO 4 12H 2 O was dissolved in 20mL of water, then added dropwise to the mixed dispersion formed in step (2), at a rate of 25 drops / min, and stirred for 4h (400r / min) in the dark at room temperature to form a precipitate;

[0044] (4) The precipitate obtained in step (3) was centrifuged, washed repeatedly with distilled water for 5 times, and dried in vacuum at 60°C for 12 hours to obtain GO / Ag 3 PO 4 (The weight of GO is Ag 3 PO 4 5% by weight (w=5%) composite photocatalyst namely GO / Ag 3 PO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com