Method for comprehensively treating construction waste materials

A construction waste, comprehensive treatment technology, applied in construction waste recycling, sustainable waste treatment, solid waste management, etc. The effect of low processing cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

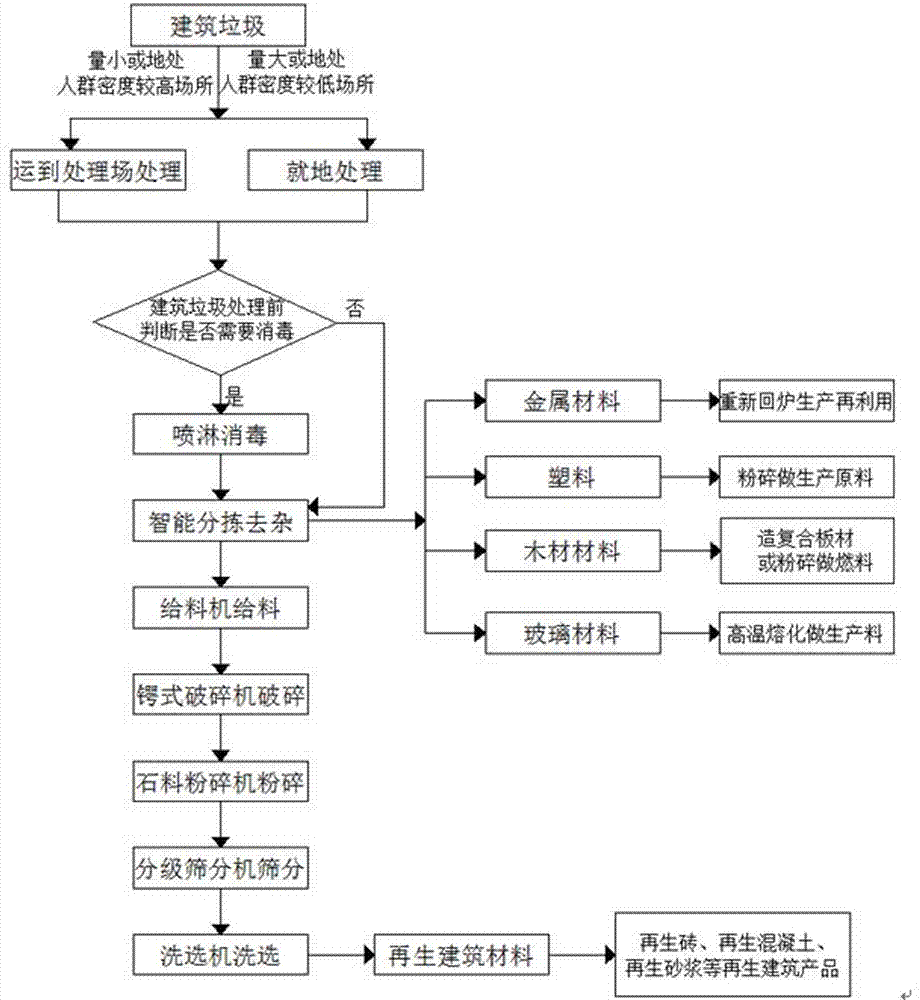

[0023] A kind of method that the present invention proposes carries out comprehensive treatment to construction waste material, comprises the following steps:

[0024] S1. According to the amount or location of construction waste, choose to transport the construction waste to the treatment site for treatment or to process it locally. For construction waste with a small amount of construction waste, choose to transport it to the treatment site for treatment. For construction waste with a large amount, choose to transport it to the treatment site for treatment. Construction waste can be recycled and processed on site by using mobile crushing station and mobile brick making machine;

[0025] S2. Determine whether disinfection treatment is required before construction waste treatment, and put hospital construction waste, virus research construction waste, microbiology research construction waste, earthquake collapse construction waste and abnormal collapse construction waste into t...

Embodiment 2

[0030] A kind of method that the present invention proposes carries out comprehensive treatment to construction waste material, comprises the following steps:

[0031] S1. According to the amount or location of construction waste, choose to transport the construction waste to the treatment site for treatment or treat it on-site. The construction waste in places with low crowd density can be recycled on-site by using mobile crushing stations and mobile brick making machines;

[0032] S2. Determine whether disinfection treatment is required before construction waste treatment, and put hospital construction waste, virus research construction waste, microbiology research construction waste, earthquake collapse construction waste and abnormal collapse construction waste into the spraying equipment, According to the mass ratio of 1:5.8, mix the mixed infusions of Asarum, Bupleurum, Folium Folium, Artemisia argyi, Cyanorrhizae, Zanthoxylum bungeanum, and Prunella vulgaris with 75% et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com