Method for manufacturing viscoelastic cushion and method for grinding plane of thin-sheet workpiece

A production method and viscoelastic technology, applied in the field of grinding processing, can solve problems such as workpiece deformation, and achieve the effects of reducing deformation problems, good fit, and good resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The shear thickening fluid is liquid under normal conditions and has fluidity. When it is loaded at a high speed, it shows a hard solid state. In addition, Kevlar, aramid fiber cloth product, has high strength properties. The combination of the two is especially suitable for the preparation of The viscoelastic pad required by the present invention is used in the grinding of thin-plate workpieces on horizontal axis and rectangular table surface grinders to reduce the clamping deformation of the workpiece and suppress the grinding vibration, thereby improving the flatness and surface quality of the processed workpiece .

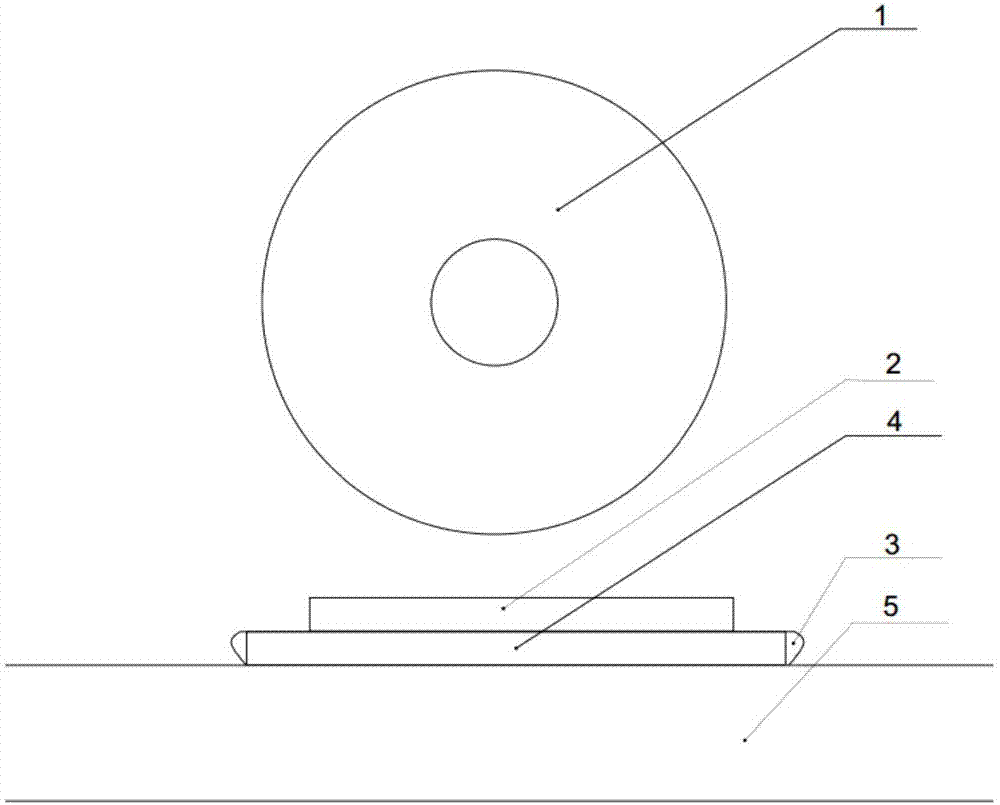

[0027] Such as figure 1 As shown, before the experiment, a three-layer Kevlar cloth 4 with a thickness of less than 1.5mm soaked in a polyethylene waterproof sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com